Basic Info.

Model NO.

Pipes110-01

Usage

Water Supply Pipe, Dredger

Length

5.8m, 11.5m, Customized Length

Working Pressure

0.6MPa ~ 1.5MPa

Flanges

Loose Flanges at Both Ends

End

Flared Ends, No Welding

Application

Dredging, Sea Oil, Port Construction, etc.

Standard Size

DN100mm

SDR

SDR26~SDR11

Transport Package

in Nude or in Steel Frames

Specification

DN100mm

Trademark

Xincheng

Origin

China

HS Code

3917210000

Production Capacity

200000ton/Year

Product Description

110mm HDPE Dredge Pipe with Flange for Dredging Project

HDPE pipe is made from wear resistant HDPE mixed with anti-UV material by extrusion molding technology.Shandong Xincheng Pipe Co., Ltd. is a professional manufacture of dredging HDPE pipes with 10years up experiences. HDPE pipes have exceptional properties such as corrosion resistance and light weight that makes them the best choice for dredging contractores.

110mm HDPE Dredge Pipe with Flange for Dredging Project

Place of Origin: Shandong, China (Mainland)

Color: Black or customized

Material: 100% virgin PE 100

Outer Diameter: 100mm

Length: 5.8m or 11.5m to fit shipping containers, certain length also available.

Working Pressure: 0.6MPa~1.5MPa

Wall Thickness: 4.2mm~10mm for different working pressure.

Accessories: carbon steel flanges rings, rubber gaskets, bolts-nuts-washers.

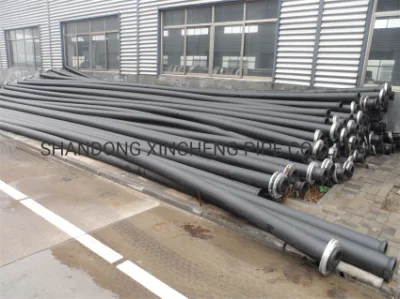

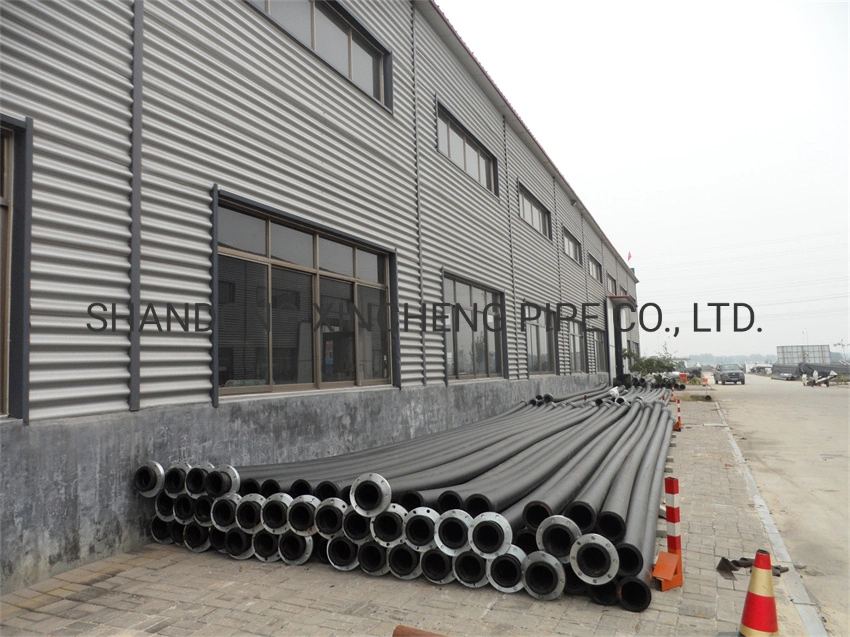

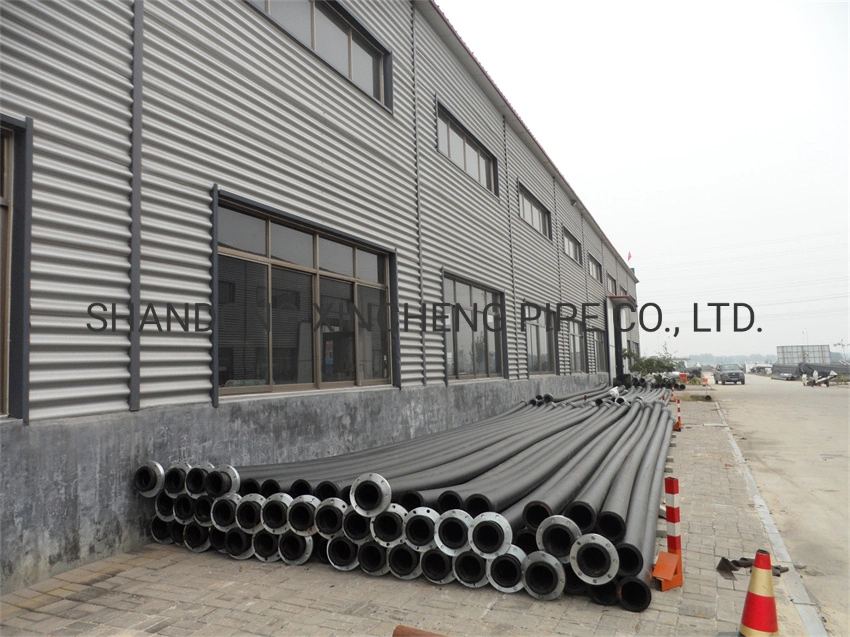

Discharge pipes in our factory

Structure and Connection of Dredging HDPE Pipes

HDPE PIPE WORKSHOP

Testing in progress for HDPE PIPE

Delivery pictures

Advantages of Discharge Pipes

1. Light weight, easy for transportaion and installation.

2. Good flexibility, tensille force and strength.

3. Strong wear resistance & corrosion resistance

4. Flared ends, no welding, loose flanges at both ends.

5. Smooth inner wall, small friction coefficient.

6. Enviromental friendly.

Xincheng manufactures dredging HDPE pipe from OD110mm to 1000mm, the sizes are as following:

Our factory Certificte

HDPE pipe is made from wear resistant HDPE mixed with anti-UV material by extrusion molding technology.Shandong Xincheng Pipe Co., Ltd. is a professional manufacture of dredging HDPE pipes with 10years up experiences. HDPE pipes have exceptional properties such as corrosion resistance and light weight that makes them the best choice for dredging contractores.

110mm HDPE Dredge Pipe with Flange for Dredging Project

Place of Origin: Shandong, China (Mainland)

Color: Black or customized

Material: 100% virgin PE 100

Outer Diameter: 100mm

Length: 5.8m or 11.5m to fit shipping containers, certain length also available.

Working Pressure: 0.6MPa~1.5MPa

Wall Thickness: 4.2mm~10mm for different working pressure.

Accessories: carbon steel flanges rings, rubber gaskets, bolts-nuts-washers.

Discharge pipes in our factory

Structure and Connection of Dredging HDPE Pipes

1. Enlarged end, or flare end some people call, No welding required.

2. Nodular cast Iron inserts at end to protect it from deformation,breaking and leakage

3. Loose flang rings (carbon steel, galvanized) at both ends

4. Rubber gasket in between when two pipes are connected by bolts and nuts.

HDPE PIPE WORKSHOP

Testing in progress for HDPE PIPE

Delivery pictures

Advantages of Discharge Pipes

1. Light weight, easy for transportaion and installation.

2. Good flexibility, tensille force and strength.

3. Strong wear resistance & corrosion resistance

4. Flared ends, no welding, loose flanges at both ends.

5. Smooth inner wall, small friction coefficient.

6. Enviromental friendly.

Xincheng manufactures dredging HDPE pipe from OD110mm to 1000mm, the sizes are as following:

| Outer Dia. / mm | Standard Size | ||||

| SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | |

| Working Pressure / MPa | |||||

| 0.6 | 0.8 | 1.0 | 1.25 | 1.6 | |

| Wall Thickness / mm | |||||

| 110 | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 |

| 125 | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 |

| 140 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 |

| 160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

| 180 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 |

| 200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

| 225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

| 250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

| 280 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 |

| 315 | 12.8 | 15.6 | 19.8 | 24.5 | 30.1 |

| 355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

| 400 | 15.3 | 19.1 | 23.7 | 29.4 | 26.3 |

| 450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

| 500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

| 560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

| 630 | 24.1 | 30.0 | 37.4 | 46.3 | 57.2 |

| 710 | 27.2 | 33.9 | 42.1 | 52.2 | |

| 800 | 30.8 | 38.1 | 47.4 | 58.8 | |

| 900 | 34.4 | 42.9 | 53.3 | ||

| 1000 | 38.2 | 47.7 | 59.3 | ||

Our factory Certificte