Basic Info.

Model NO.

PE Gas pipe -5

Kind

Thermoplastics Pipes

Water Absorption

<0.01%

Contraction Percentage

<0.4%

Tensile Strength

3.9MPa

Color

Custom Made

Transport Package

Plastic Bag

Specification

16-2000MM

Trademark

fosite

Origin

China

HS Code

391721000

Packaging & Delivery

Package Size

50.00cm * 30.00cm * 30.00cm

Package Gross Weight

8.500kg

Product Description

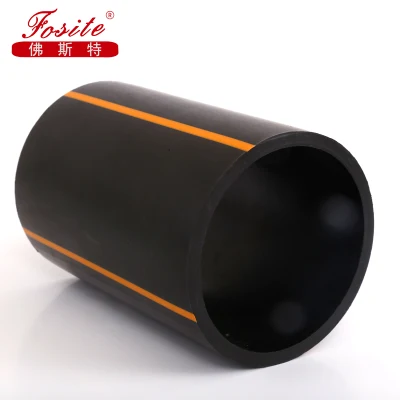

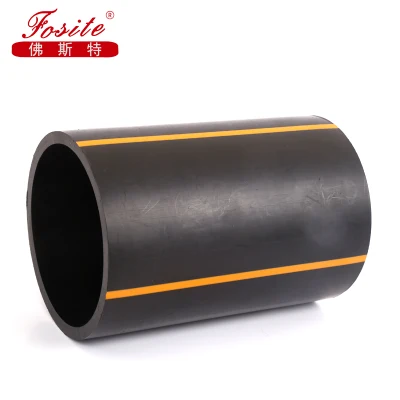

HDPE Gas Pipe

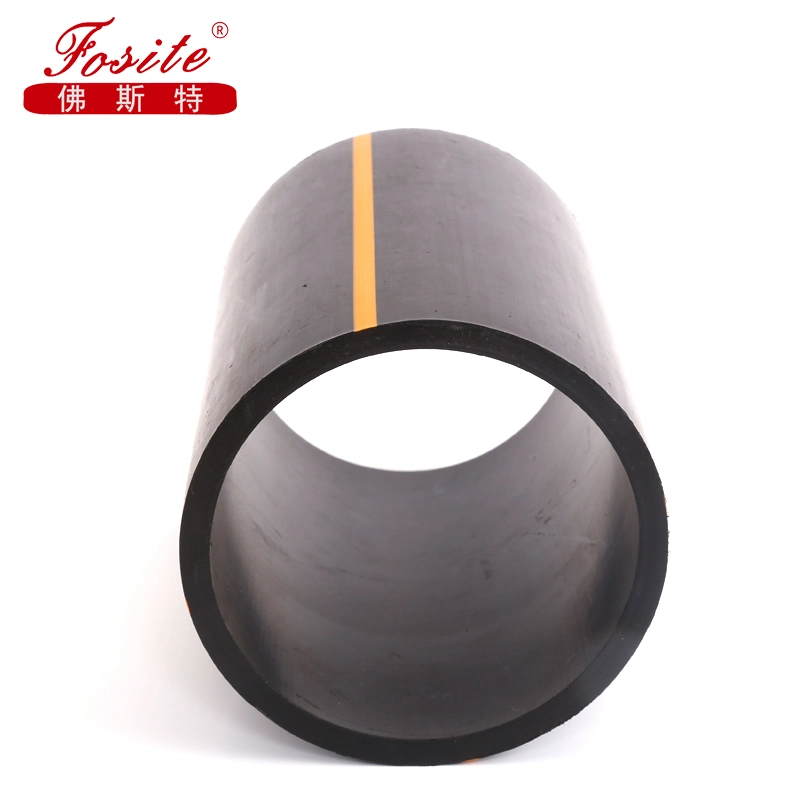

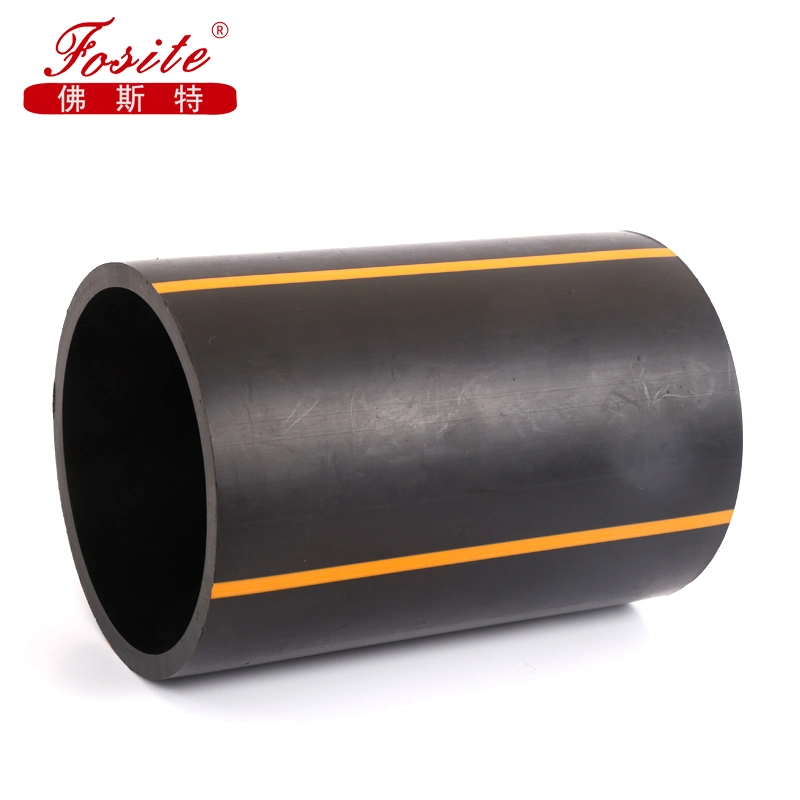

HDPE Pipe for Gaseous FuelsDiameter: 16mm-630mm

Thickness: 3.0mm-57.3mm

Pressure: 1.6Mpa,1.0Mpa, 0.6Mpa, 0.4Mpa, 0.2Mpa

Length: 5.8m/11.9m or as required

Standard:GB15558.1-2003, BS EN 1555-2-2010

Material: High density polyethylene

Color: Black with yellow stripe

Product Description

Material:PE80 and PE100.non-toxic, imported from Borealis , SABIC , demostic or upon request.Size: full 16mm through 630mm availability

Pressure Rating: SDR11(1.6Mpa),SDR17(1.0Mpa),SDR21(0.8Mpa),SDR26(0.6Mpa).

Not required of anti-corrosion treatment ,Light weight ,rarely maintenance.

Spanlife:Over 50 years.

Colors:PE80 Pipe: black with yellow stripes,

PE100 Pipe: orange, black with orange stripes, other colors upon request.

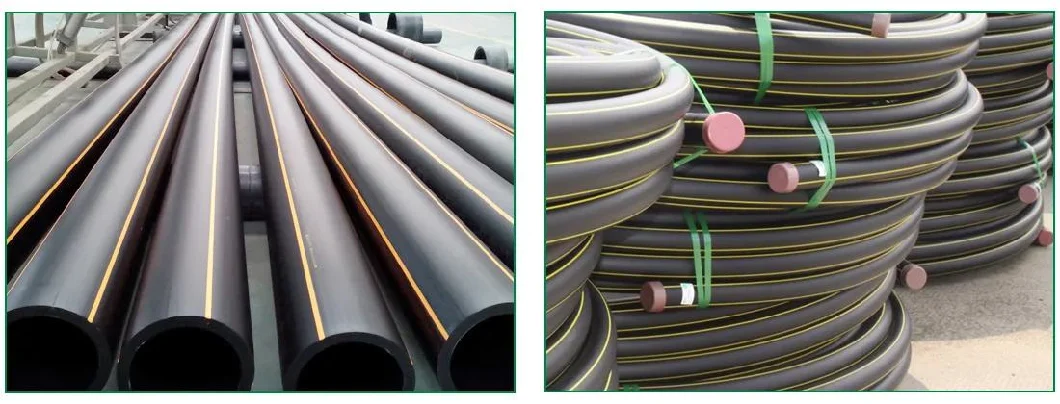

Form Supplied:

9 meters straight length (dn>63)

100 meters coil length (dn40~dn63)

200 meters coil length (dn20~dn32)

Other forms are also available upon request.

Specially customized for SDR21 and SDR26 of non-buried gas pipe.

Advantages

Non-toxic PE raw materials' imported from Borealis , SABIC ,SINOPEC and upon request.Inner wall smoothly, with high gas flow speed: 20 m/s.

Good toughness, Effectively resistance to earthquake and foundation settlement. Climate changed resistance, Wear Resistance,

Anti-low temperature with impact resistance,no affected working in winter,

Working temperature: from -20ºC to 40ºC.

Not required of anti-corrosion treatment, saving cost.

Span life: Over 50 years.

Lightweight for easy to transport and installation, rarely maintenance.

Joint Method: butt fusion joint, electro fusion joint and ball valve connection.

Specification

| PE100 | 0.4MPa | 0.5MPa | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa |

| Outside Diameter | PN4 | PN5 | PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 |

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | SDR7.4 | |

| Wall Thickness (en) | |||||||||

| 20 | - | - | - | - | - | - | 2 | 2.3 | 3 |

| 25 | - | - | - | - | - | 2 | 2.3 | 3 | 3.5 |

| 32 | - | - | - | - | 2 | 2.4 | 3 | 3.6 | 4.4 |

| 40 | - | - | - | 2 | 2.4 | 3 | 3.7 | 4.5 | 5.5 |

| 50 | - | - | 2 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | - | - | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | 8.6 |

| 75 | - | - | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | 10.3 |

| 90 | - | - | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | 12.3 |

| 110 | - | - | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | 15.1 |

| 125 | - | - | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | 17.1 |

| 140 | - | - | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | 19.2 |

| 160 | - | - | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | 21.9 |

| 180 | - | - | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | 24.6 |

| 200 | - | - | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | 27.4 |

| 225 | - | - | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | 30.8 |

| 250 | - | - | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | 34.2 |

| 280 | - | - | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | 38.3 |

| 315 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 | 43.1 |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 | 48.5 |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | 54.7 |

| 450 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | 61.5 |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | - |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | - |

| 630 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 | - |

| 710 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 | - |

| 800 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 | - |

| 900 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | - | - |

| 1000 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | - | - |

| 1200 | 29.4 | 36.7 | 45.9 | 57.2 | 67.9 | 88.2 | - | - | - |

| 1400 | 34.3 | 42.9 | 53.5 | 66.7 | 82.4 | 102.9 | - | - | - |

| 1600 | 39.2 | 49 | 61.2 | 76.2 | 94.1 | 117.6 | - | - | |

Applications

It can be installed by heat fusion or mechanical fittings. The product's physical properties make it applicable to open-trench and slip-lining installations. Precautions

DO:Keep the pipes and fittings away from sharp objects, heat sources and toxic and corrosive materials.

Before installation, keep the protective packaging intact.

Prevent dust or other materials from entering the pipe.

DO NOT :

Throw pipe from delivery vehicles.

Place pipe and fittings incontact withlubricating oil, gasoline, solvents or other aggressive materials.

Heat pipe with an open flame.

Certification

Packaging

Roll with plastic bag or without package

Related Industry

Our Company

FAQ

Q: What is your MOQ?A: As customer's request.

Q: Why choose us?

A: We are leading professional manufacturer of HDPE/PVC/PPR pipes&fittings, we offer one stop pipeline system with competitive price.

Q: How to buy the product?

A: You can contact our trade manager by Email, Wechat, Phone number or Whatsapp, and send us the BOQ list, we will contact you immediately. The more specific product information you provide, the faster and easier you can get a quote.

Q: Can I make my own design and logo on the product?

A: Yes, we do OEM. Welcome partners from globally, we can produce your product in China.

Q: Do you have customized pipe and fittings?

A: We can make any plastic pipes and fittings according to customers drawings.