Basic Info.

Section Shape

Round

Transport Package

Loading Belt, Woven Bag

Specification

219mm- 3520mm

Trademark

PMC

Origin

Cn

Production Capacity

800000ton/Year

Product Description

Description of SSAW Steel Pipes:

| Product | SSAW Steel Pipes |

| OD | 219mm(8")- 3520mm(138") |

| WT | 0.8-25.5mm |

| Length | 0.3-18m( customized) |

| Standard | API 5L PSL1&PSL2, ASTM A252, AS1163 |

| Grade | API 5L : GR B, X42,X46, X56, X60,X65,X70 ASTM A252 Grade 250 AS1163 C350 |

| Surface | Black painting, Varnish painting, bare pipe, Oiled,customized coating(3LPE/FBE/Concrete Weight Coating/Insulation Coatin/Bitumen Coating) |

| Package | 1. not bundled, in loose piece 2. customized requirement |

| Usage | Oil&GAS INDUSTRY/ CONSTRUCTION/PILING/MINING SEWAGE TRANSMISSION etc. |

Standard and Classfication:

| Classfication | Standard | Main Products | |||||||||||||||

| Steel Pipe for Fluid Service | GB/T 14291 | Welded pipe for mine fluid sevice | |||||||||||||||

| GB/T 3091 | Welded pipe for low pressure fluid service | ||||||||||||||||

| SY/T 5037 | Spirally submerged arc welded steel pipe for pipelines for low pressure fluid service | ||||||||||||||||

| ASTM A53 | Black and hot-hipped galvanized welded and seamless steel pipe | ||||||||||||||||

| BS EN10217-2 | Welded steel tybes for pressure purposes - delivery technical conditions - part2: Electric welded non- alloy and alloy steel tubes with specified elevated temperature properties | ||||||||||||||||

| BS EN10217-5 | Welded steel tybes for pressure purposes - delivery technical conditions - part5: submerged arc welded non-alloy and alloy steel tubes with specified elevated temperature properties | ||||||||||||||||

| Steel Pipe for Ordinary Structure | GB/T 13793 | Longitudinally electric resistance welded steel pipe | |||||||||||||||

| SY/T 5040 | Spirally submerged arc welded steel pipe piles | ||||||||||||||||

| ASTM A252 | Welded and seamless steel pipe piles | ||||||||||||||||

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels - part1: Technical delivert conditions | ||||||||||||||||

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels - part2: tolerances dimmsions and sectional properties | ||||||||||||||||

| Line Pipe | GB/T 9711.1 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class A steel pipe) | |||||||||||||||

| GB/T 9711.2 | Steel pipe for pipeline transportation system of petroleum and natural gas industries(Class B steel pipe) | ||||||||||||||||

| API 5L PSL1/2 | Line pipe | ||||||||||||||||

| Casing | API 5CT/ ISO 11960 PSL1 | Steel pipe for use as casing or tubing for wells of petroleum and natural gas industries | |||||||||||||||

PIPE PICTURE:

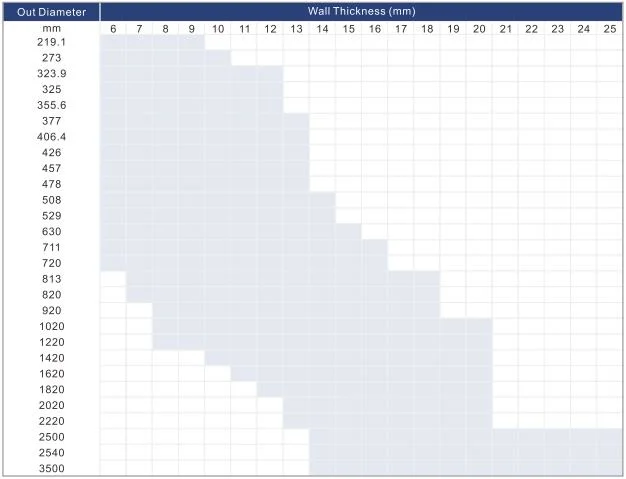

Size for SSAW Steel Pipes:

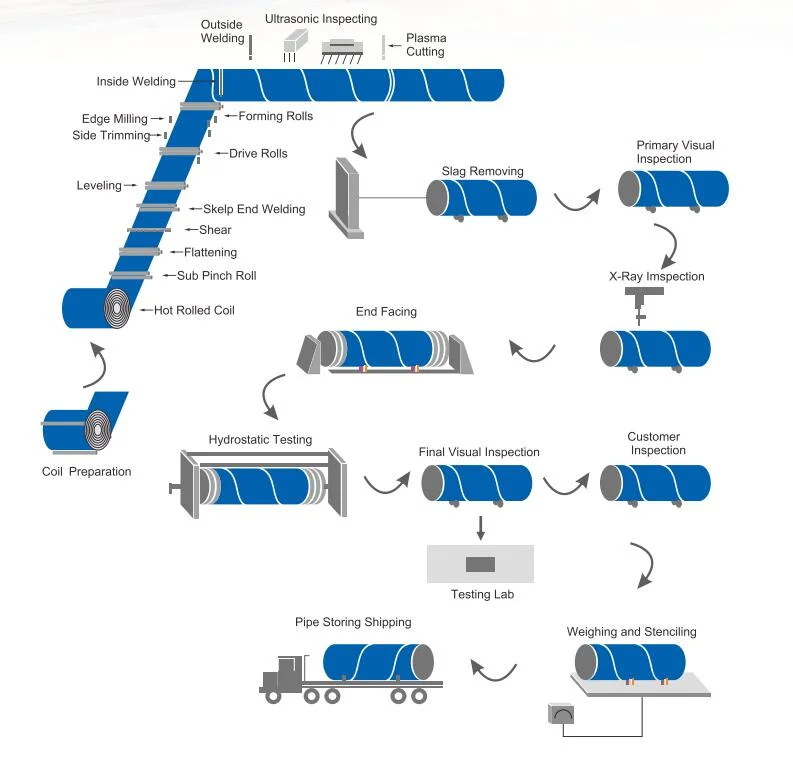

Process Flowchart of SSAW Steel Pipes

Coil probe: steel coil into the production line, the fifirst full board Ultrasonic Inspection

Leveling milling: through anvil plate leveling machine so that the original curl, and then pass the two edges of steel-sided milling machine milling, so that up to the requirements of the plate width, plate edge parallel groove shape

Cut type: steel production line along the outer edge of the coiled-coil tube

Welding and cutting: the use of advanced technology for pre double submerged arc welding cutting inside from the foot of the welding specifification welded steel pipe welded outside use, etc.

Visual inspection: some basic parameters by a professional technician check

Ultrasonic flflaw: the inner and outer sides of the base metal and weld seam 100% inspection

X-ray detection: internal and external welds 100% X-ray television industry checks, the use of image processing system ensures detection sensitivity

Pressure test: hydrostatic testing machine by-root test steel pipe up to the standard requirements to ensure that the test pressure

Chamfer level: steel pipe inspection pipe end processing, up to the requirements of the pipe end beveling size

Check: X-rays and then subjected to ultrasonic testing and magnetic particle inspection conducted pipe end, check whether the deposit welding problems and defects in the pipe ends

Oiled marking: Qualifified oiled steel pipe corrosion and in accordance with user requirements for marking

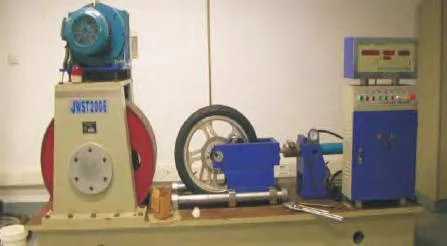

Production equipment of SSAW Steel Pipes

| Standard | Tolerance of Pipe Body | Tolerance of Pipe End | Tolerance of Wall Thickness | |||

| Out Diameter | Tolerance | Out Diameter | Tolerance | ≤±10% | ||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ||

| 48.3<OD≤273.1mm | ≤±1.0% | 48.3<OD≤273.1mm | - | |||

| 273.1<OD≤508mm | ≤±0.75% | 273.1<OD≤508mm | -0.8~+2.4 | |||

| OD>508mm | ≤±1.0% | OD>508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3<OD≤457mm | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508<OD≤941mm | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD>941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60<OD≤610mm | ±0.75%D~±3mm | 60<OD≤610mm | ±0.5%D~±1.6mm | 4mm<WT<25mm | ±12.5%T~±15.0%T |

| 610<OD≤1430mm | ±0.5%D~±4mm | 610<OD≤1430mm | ±0.5%D~±1.6mm | WT≥25mm | -3.00mm~+3.75mm | |

| OD>1430mm | - | OD>1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD<508mm | ≤±0.75% | OD<508mm | ≤±0.75% | OD<508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD<60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | WT≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3<OD≤610 | ≤±1.6mm | 5.0<WT<15.0 | ≤±0.1T | |

| 168.3<OD≤610 | ≤±0.75% | 610<OD≤1422 | ≤±1.6mm | WT≥15.0 | ≤±1.5 | |

| 610<OD≤1422 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | |||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

Quality inspection of SSAW Steel Pipes

Permanent Steel Manufacturing is committed to comply with the requirement of the established Quality Management System(QMS) in accordance with the requirement of API Specifification Q1 and ISO 9001:2008 Standard and strive for continually improve QMS effectiveness and customer satisfaction through competitiveness and effificiency in manufacturing of steel pipe and steel related services.

Our Some Projects

About us

Permanent Steel Manufacturing Co.,Ltd has been committed to being a major supplier of quality kinds of carbon steel pipe, stainless steel tube, hollow section, numerous types of piping equipments including Bend, Cap, Coupling, Elbow, Reducer, Stub End, Tee, Olet, Joint, Gasket, etc.

The Products from Permanent Steel Manufacturing Co.,Ltd are supplied in accordance with appropriate International Standards as well as Customer Specifications in a large variety of steel grades and dimensions.

Permanent Steel Manufacturing Co.,Ltd on a 250,000 m2 area and has three production units: Foundry, Rolling and Extrusion mills. Permanent Steel Manufacturing Co.,Ltd operates under strict quality, environmental, as well as health and safety management systems, in compliance with ISO 9001, ISO 14001 and OHSAS 18001 standards.

The Products from Permanent Steel Manufacturing Co.,Ltd are supplied in accordance with appropriate International Standards as well as Customer Specifications in a large variety of steel grades and dimensions.

Permanent Steel Manufacturing Co.,Ltd on a 250,000 m2 area and has three production units: Foundry, Rolling and Extrusion mills. Permanent Steel Manufacturing Co.,Ltd operates under strict quality, environmental, as well as health and safety management systems, in compliance with ISO 9001, ISO 14001 and OHSAS 18001 standards.

FAQ

Q: Are you trading company or manufacturer?

A: We are a sino-Singapore joint venture group company which have our own invest factory.

steel pip

Q: How long is your delivery time?

A: Depends on pipes size and quantity. 7-10 days for stocked steel pipe and 20-40 days for new productions according to quantity.bowl shape stainless steel smoking pipe screens

Q: Do you provide samples? Is it free or extra? 201 Stainless Steel Pipe used for Food and Chemical Industry

A: Yes,we could offer free steel pipe sample for your evaluation. stainless steel pipe fitting

Q: What is your terms of payment? steel pipe

A: 20%+80% T/T or 100% irrevocable L/C at sight, the specific payment should be addressed by further discussion.