Basic Info.

Product Description

HDPE Compression Fittings, PP compression fittings, HDPE Compression Female Tee, Compression Female Tee, HDPE female Tee, Poly Female Tee, PP Compression Female Tee, HDPE pipe Female Tee

A HDPE compression female tee is used to tee off a length of metric HDPE pipe with a male threaded pipe offtake. This is often used to fit a male-threaded valve or tap via compression fitting, to a HDPE pipeline. PP Compression female tee fittings are often used for irrigation and hydroponics, as they can fit a valve/tap right next to the main pipeline, to adjust flow to the off-take pipeline.

HDPE female tee compression can be manufactured in a diameter sizing from 20*1/2"*20mm to 110*4"*110mm, with pressures up to 16 bar.

SUNPLAST PP Compression Fittings range have a heterophasic black polypropylene body suitable at high temperatures, with a polyacetal resin clinching ring and a blue dyed PP nut offering suitability to UV rays and system heat. These fittings also use an acrylonitrile rubber or lip seal gasket, based on the different fitting diameters.

PP compression tee fittings are consisted of 5 palstic accessories:

| Mark | Part Name | Material | Color |

| A | Cap | High quality polypropylene black co-polymer (PP-B) | Blue |

| B | Clinching Ring | POM resin | White |

| C | Blocking Bush | High quality polypropylene black co-polymer (PP-B) | Black |

| D | "O" Ring Gasket | NBR rubber | Black |

| E | Body | High quality polypropylene black co-polymer (PP-B) | Black |

More brief details as below:

| Product | HDPE Compression Equal Tee, Compression tee, Poly Compression tee, Compression Tee fittings, HDPE compression tee, PP Compression Tee |

| Specification | 20mm to 110mm |

| Pressure ratings | Working Pressure at 20ºC: 20~63mm in PN16; 75~110mm in PN10 |

| Material | High quality polypropylene black co-polymer (PP-B) |

| Color | Black body / Blue Cap |

| Manufacturing Standard | Dimensions and characteristics: ISO 3501/3503/3458/3459. To be installed on HDPE pipes: ISO 11922; DIN 8072/8074; Threads (BSP): ISO 7; DIN 2999. |

| Samples available | Yes, samples are available, but charged. |

| Packing method | Cartons |

| MOQ | Negotiable |

| Customized Logo available (OEM Service) | For small quantity of order, customer logo can be marked on the fittings by laser marking or sticker. For big quantity of order, customer logo can be embossed on the fittings. |

| Production lead time | Mass stock available for regular sizes About 10 days for a 20ft container, 20 days for a 40ft container |

| Warranty time | 1 years for normal use |

| Payment term | T/T, L/C, DP, Western Union, or negotiable |

| FOB loading port | Ningbo/Shanghai China |

| Place of origin | Ningbo, China |

Product Specifications

HDPE/PP compression tee fittings can be manufactured sizing from 20mm to 110mm. The size 20-63mm with a pressure of PN16, and 75-110mm pressurized in PN10.

| Size (mm) | Pressure Rating (bar) | Weight (gram/PCS) | Packing (PCS/CTN) |

| 20*1/2"*20 | PN16 | 87 | 195 |

| 20*3/4"*20 | PN16 | 88 | 180 |

| 25*1/2"*25 | PN16 | 125 | 120 |

| 25*3/4"*25 | PN16 | 132 | 120 |

| 25*1"*25 | PN16 | 130 | 112 |

| 32*1/2"*32 | PN16 | 197 | 80 |

| 32*3/4"*32 | PN16 | 198 | 80 |

| 32*1"*32 | PN16 | 207 | 80 |

| 40*1"*40 | PN16 | 388 | 48 |

| 40*1-1/4"*40 | PN16 | 368 | 48 |

| 50*1-1/4"*50 | PN16 | 560 | 26 |

| 50*1-1/2"*50 | PN16 | 580 | 26 |

| 63*1-1/2"*63 | PN16 | 1162 | 13 |

| 63*2 1/2"*63 | PN16 | 1162 | 12 |

| 63*2"*63 | PN16 | 1112 | 13 |

| 75*2"*75 | PN10 | 1308 | 9 |

| 75*2-1/2"*75 | PN10 | 1286 | 9 |

| 75*3"*75 | PN10 | 1334 | 9 |

| 90*2-1/2"*90 | PN10 | 1989 | 5 |

| 90*3"*90 | PN10 | 1998 | 5 |

| 90*4"*90 | PN10 | 1971 | 5 |

| 110*3"*110 | PN10 | 3327 | 3 |

| 110*4"*110 | PN10 | 3308 | 3 |

Benefits Of HDPE Compression Fittings

There are multiple benefits to using HDPE compression fittings in your piping systems. Some of the main advantages include:

Easy to assemble and disassemble without the need for special tools

Low maintenance over time, which makes the piping system last longer

No soldering required, which is especially beneficial for areas where no soldering is allowed

Light-weight in comparison to other materials, which assists in making the assembly quick and more effective

Leak-free jointing is ensured via heat-infused joints to ensure strong connections

Leak-free connections, provided they are installed correctly

Corrosion resistant due to being HDPE. They won't rust or disintegrate, even after continuous exposure to water or liquids

Can handle water surges due to excellent water hammer capabilities

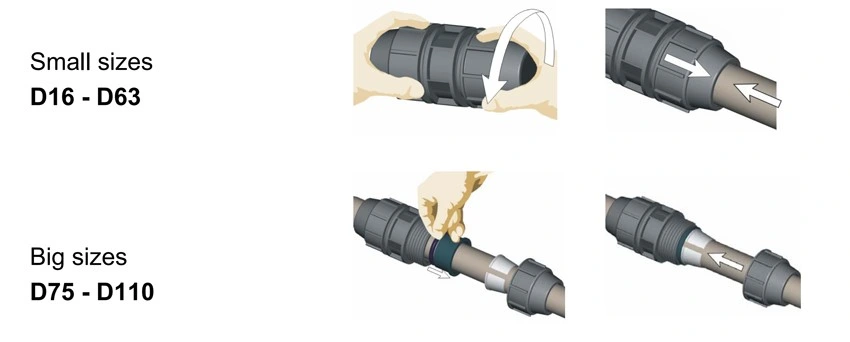

Installation procedure For HDPE Compression Fittings

HDPE Pipe Compression fittings provide a a easy & simple installation for HDPE pipe without welding. It allows joining of pipe in a few easy steps. Simply cut, chamfer and clean the pipe, loosen the compression nut on the fitting, insert the pipe into the fitting until it bottoms out, and mechanically tighten the nut. When properly completed, your new connection is immediately ready for pressure.

1. Pipe ends must be cut square and burr-free before using with the fittings. Chamfer

may be provided on the pipe end to facilitate ease of pipe insertion.

2. No need to open fitting & take apart components separately. Just loosen the QJN

(Quick Joint Nut) by three to four turns.

3. Insert the pipe into the fitting up to the stopper.

4. Hand Tighten the QJN for fittings up to 32 mm.

5. Use Wrench to tighten the QJN after hand tightening for fittings 40 mm and above.

6. After Firm Hand Tightening, Tighten the QJN with wrench only for a quarter turn.

Why Choose Us?

Rich experience on manufacturing HDPE fittings over 20 years, we are an expert in this industry.

Full product range available, you will always find the right solution here.

Strong after-sale term supports to provide professional guide for installation.

By using top quality raw material, with long warranty time on quality.

Short lead time to satisfy your urgent need request.

Quick reply for your inquiries within 12 hours.

OEM service available to support a good sale in customers' market.

Contact Us

If you have any requirements on PP compression fittings, or any question on our fittings, please contact us freely. SUNPLAST has well trained staff who are available to address your needs and provide technical support to all sectors when needed.