- Overview

- Product Description

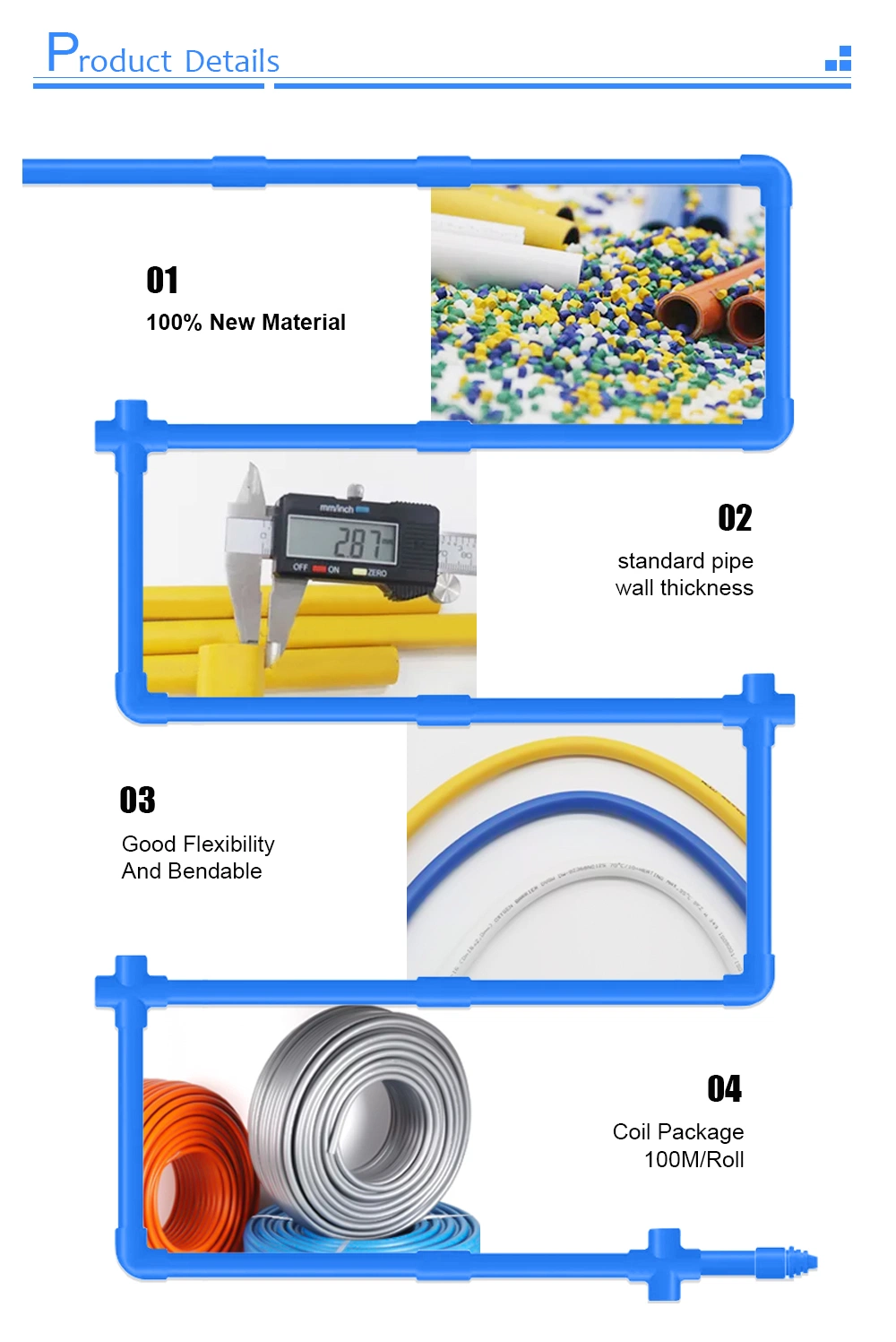

- Product Details

- Features

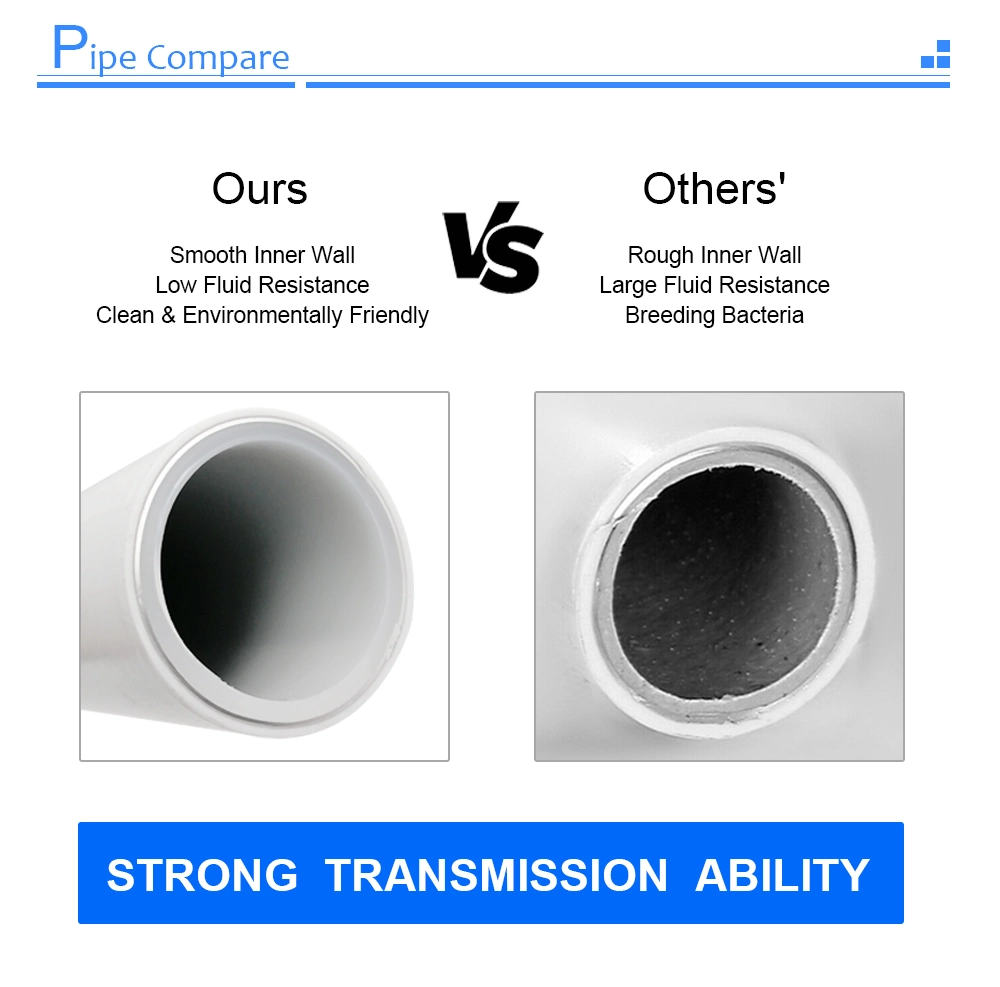

- Pipe Compare

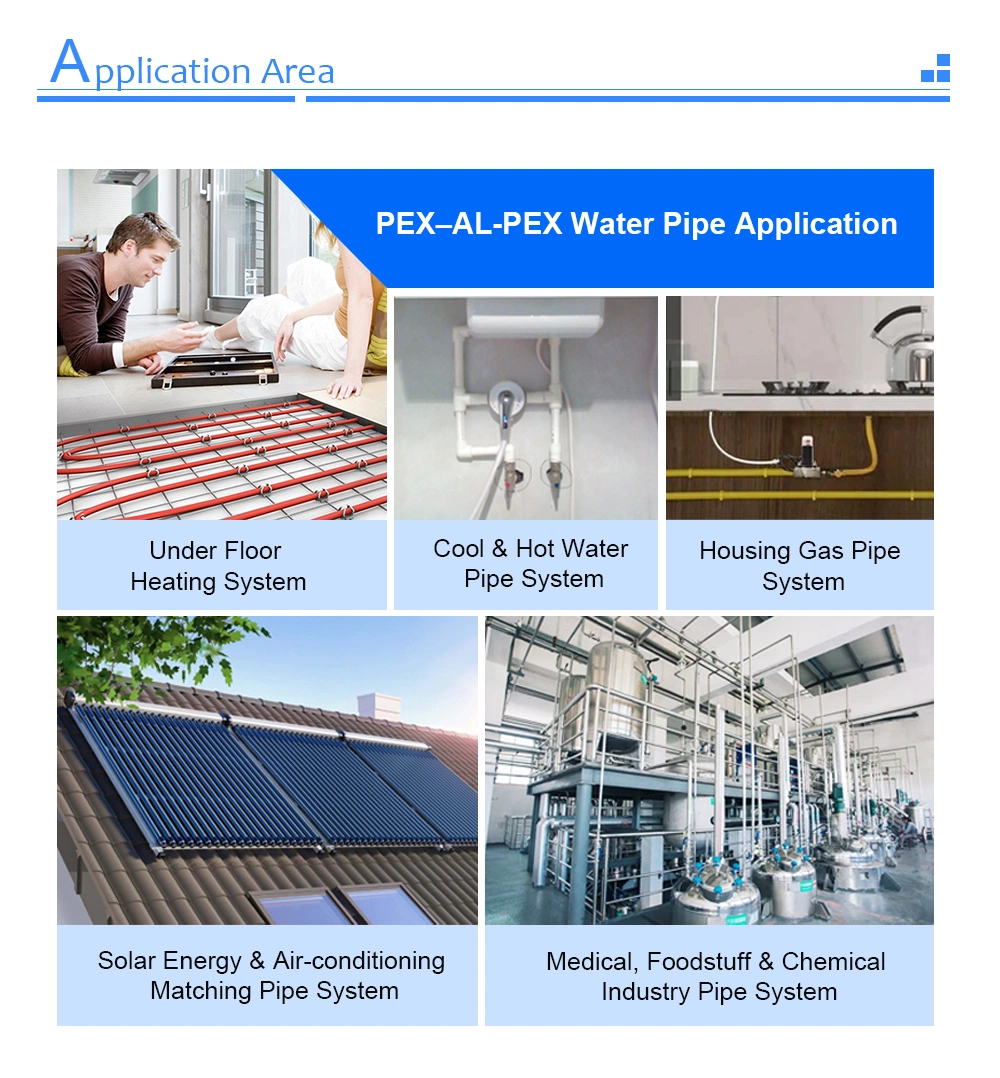

- Application Area

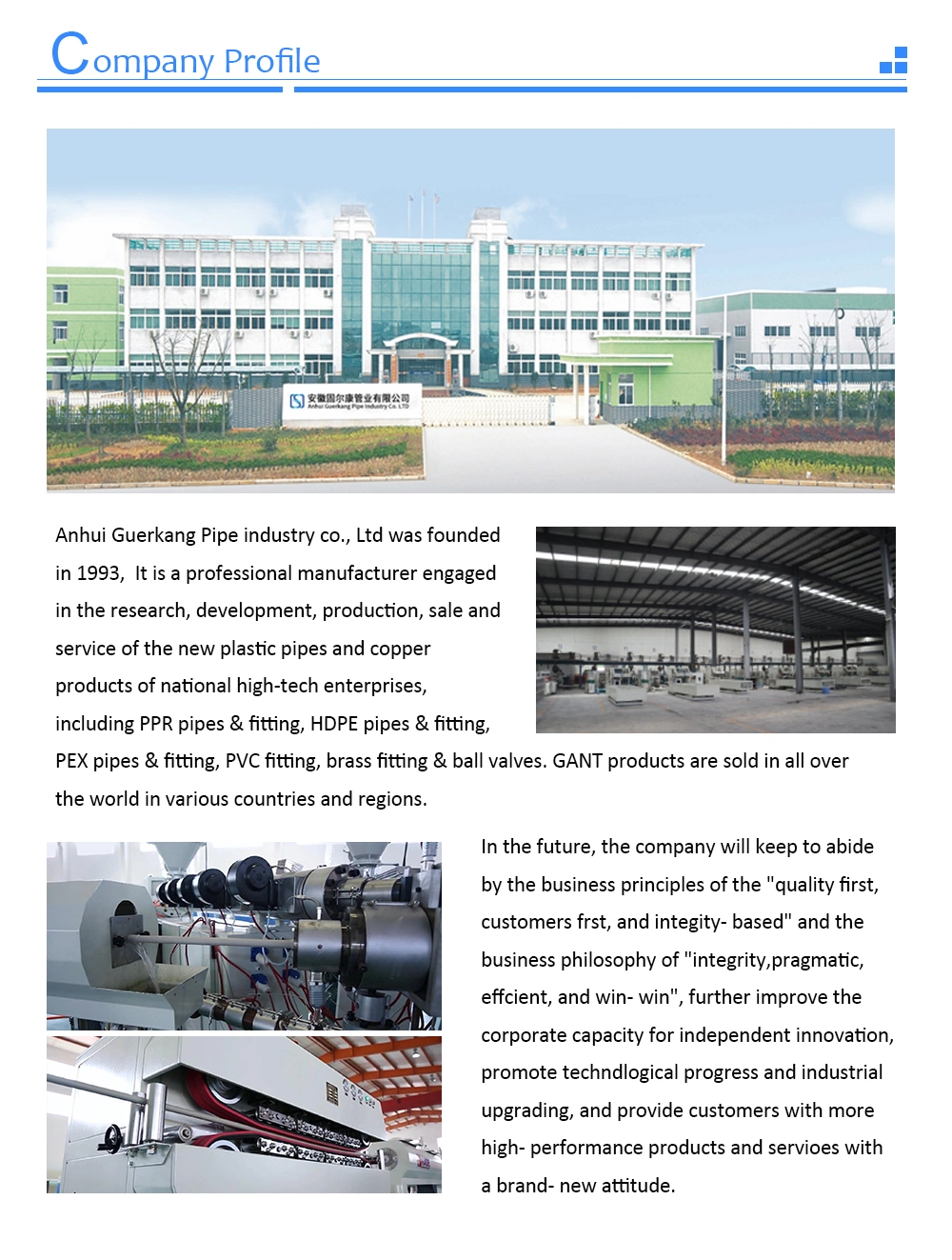

- Company Profile

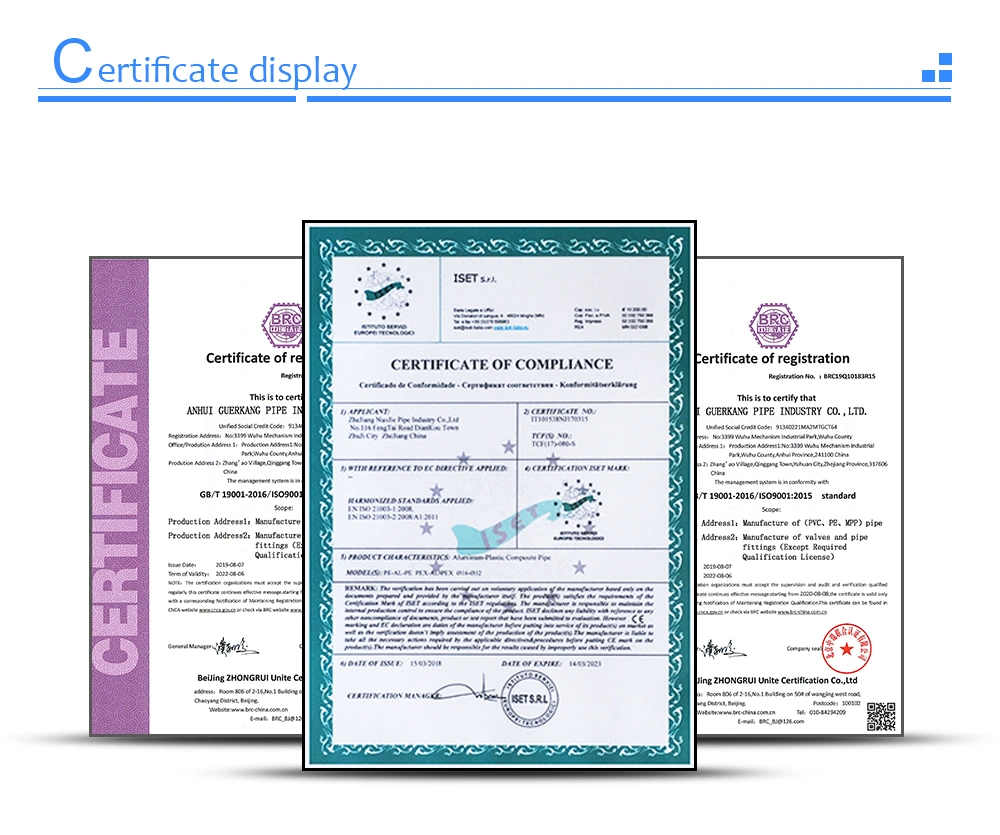

- Certifications

- Packaging & Shipping

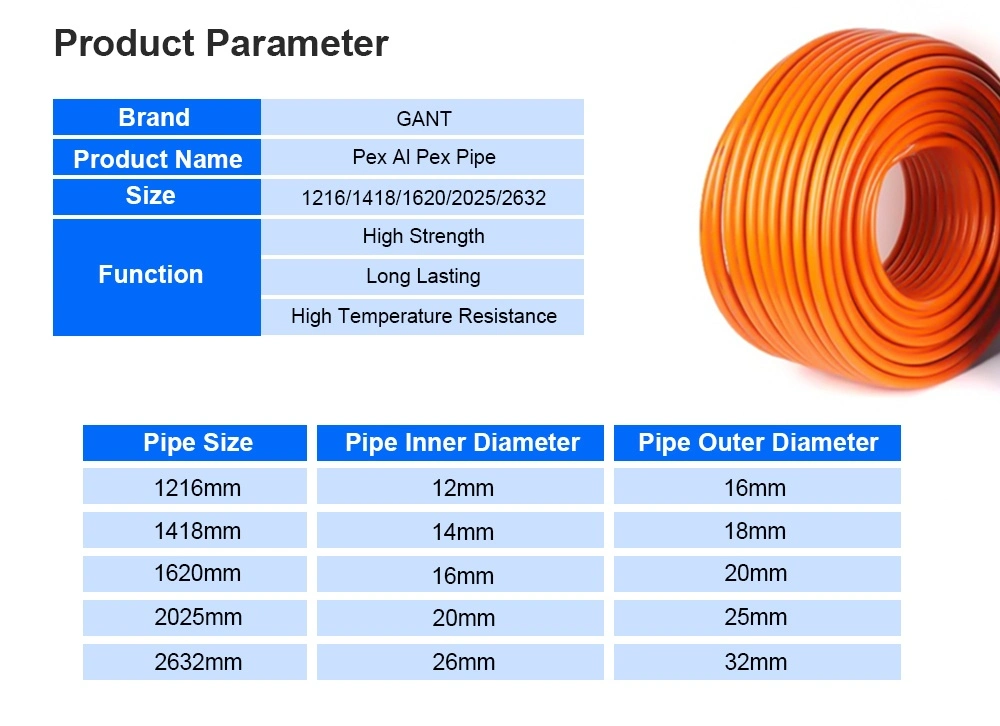

Basic Info.

Model NO.

PEX Al PEX Pipe

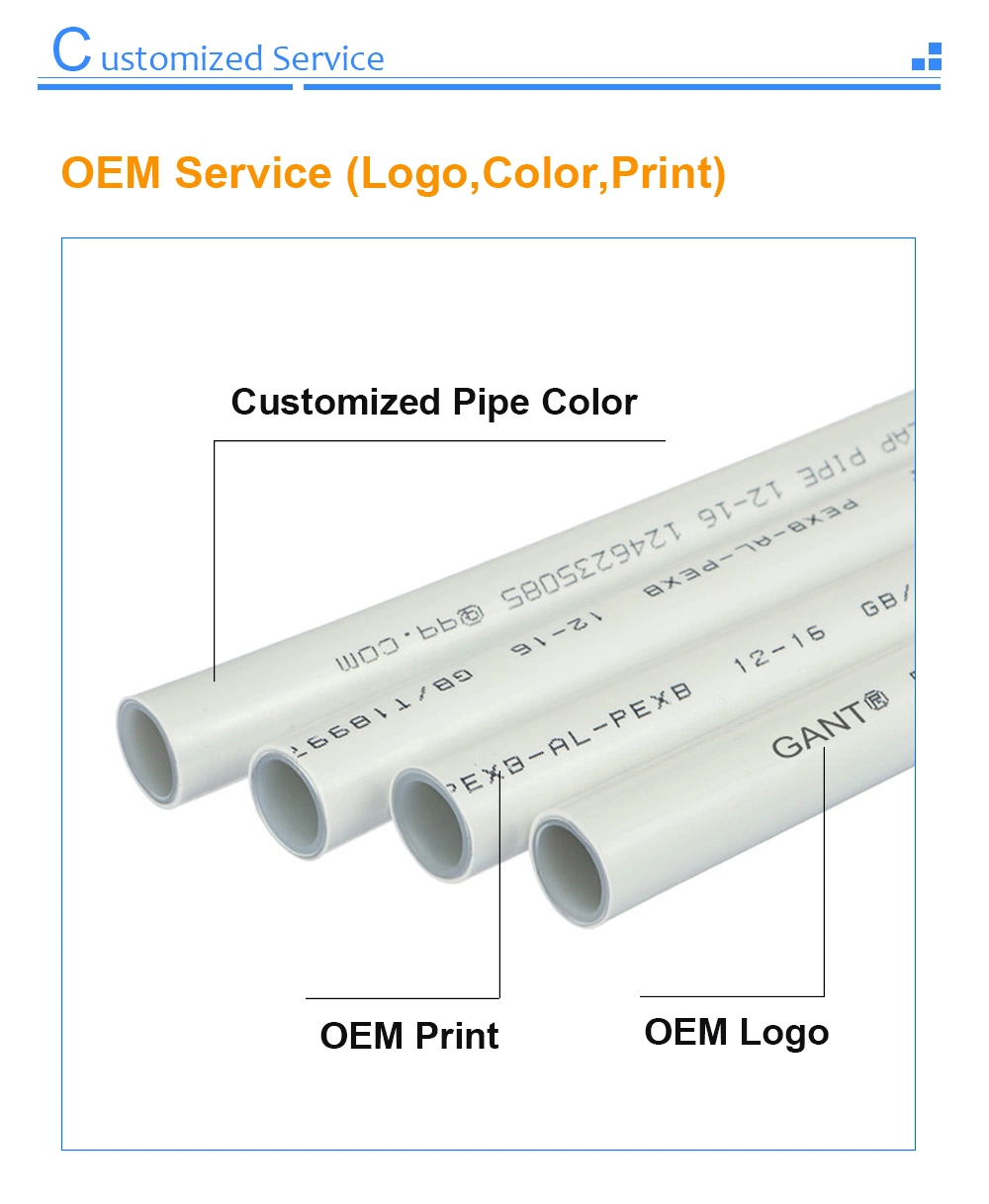

Color

White, Customized

Crosslink

≥65°

Type of Crosslink

Pex B

Grannules Class

≥PE80

Max. Working Temp

95ºC

Min. Working Temp

-40°c

Working Pressure

≤1, 25 MPa

Bursting Strenght for +95°c

≥45 Bar

Resistance to Delamination

≥ 9 N/mm

Tensile Strenght Cone

Acc. Dvgw W 542

Thermal Durability

Acc. ISO 21003-2

Marking

Customized

Thermal Conductivity

0.45W/Mk

Thermal Expansivity

0, 025 mm/Mk

Bend Radius

5xd Ext.

Transport Package

Packing in Rolls in Plastic Films, Customized

Specification

16/20/25/32

Trademark

GANT, OEM

Origin

China, Anhui

HS Code

3917390000

Production Capacity

30000000meters

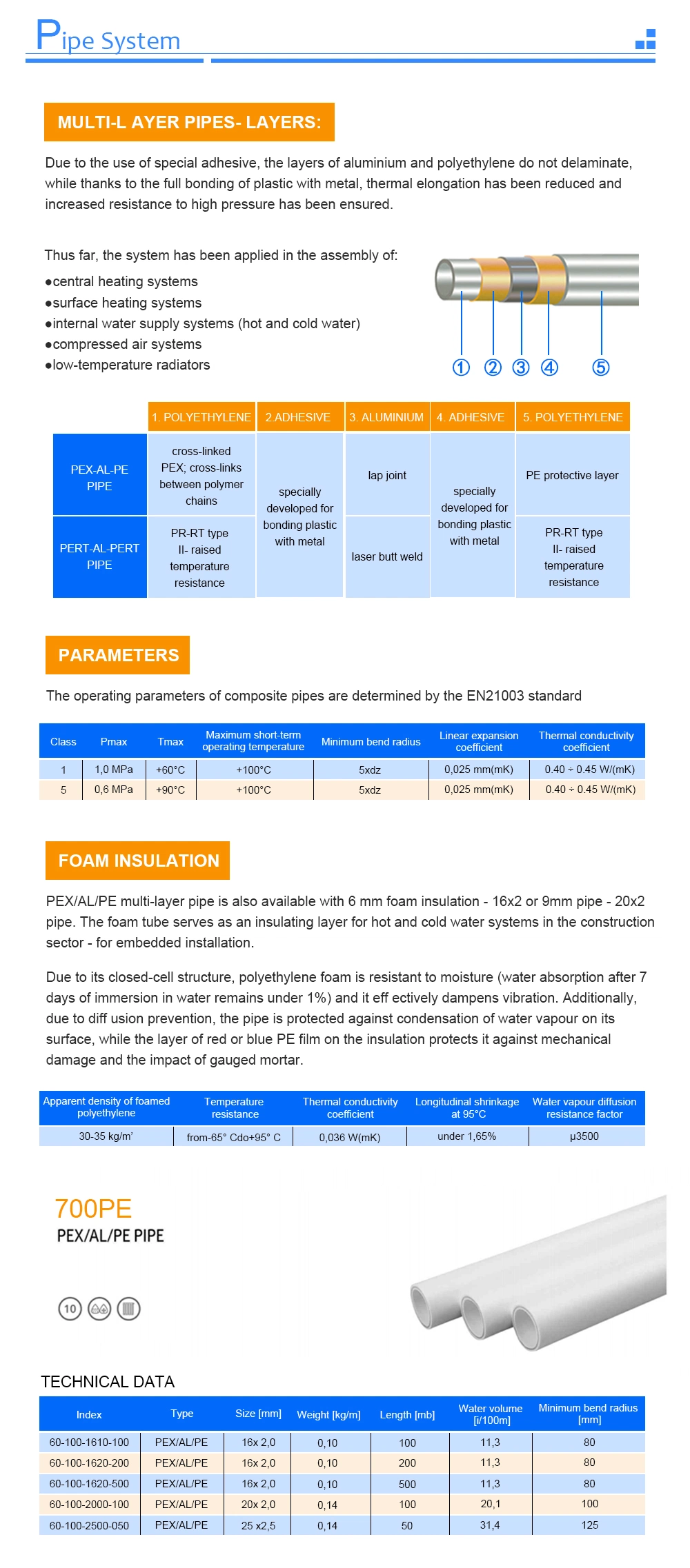

Product Description

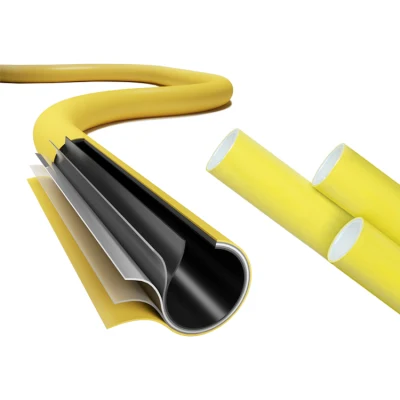

PEX Al PEX Pipe

PEX Al PEX Pipe is a new type of high-quality pipe material, which is composed of two layers of polyethylene (PEX) with aluminum foil sandwiched between them. It is widely used in construction and industrial fields, bringing convenience and comfort to our production and life.

Advantage:

1. Anti-leakage: PEX aluminum-plastic pipe is packed with a layer of aluminum-plastic composite material, which makes it more pressure-resistant, anti-leakage, and longer service life.

Advantage:

1. Anti-leakage: PEX aluminum-plastic pipe is packed with a layer of aluminum-plastic composite material, which makes it more pressure-resistant, anti-leakage, and longer service life.

2. Both hardness and softness: the outer layer of the PEX aluminum-plastic pipe is made of a layer of aluminum-plastic composite material, which makes the pipe not only have good hardness, but also good flexibility.

3. Strong corrosion resistance: The inner wall of the PEX aluminum-plastic pipe is made of PEX material, which has the characteristics of not easy to age, corrosion resistance, etc., and has a long service life.

4. Not easy to burn: The outer layer of the PEX aluminum-plastic pipe is made of aluminum-plastic composite material, which is easy to decompose, not easy to burn, and has good safety.

3. Strong corrosion resistance: The inner wall of the PEX aluminum-plastic pipe is made of PEX material, which has the characteristics of not easy to age, corrosion resistance, etc., and has a long service life.

4. Not easy to burn: The outer layer of the PEX aluminum-plastic pipe is made of aluminum-plastic composite material, which is easy to decompose, not easy to burn, and has good safety.

5. Strong corrosion resistance: The inner and outer surfaces of PEX aluminum-plastic pipes are made of high-quality materials, which have good corrosion resistance.

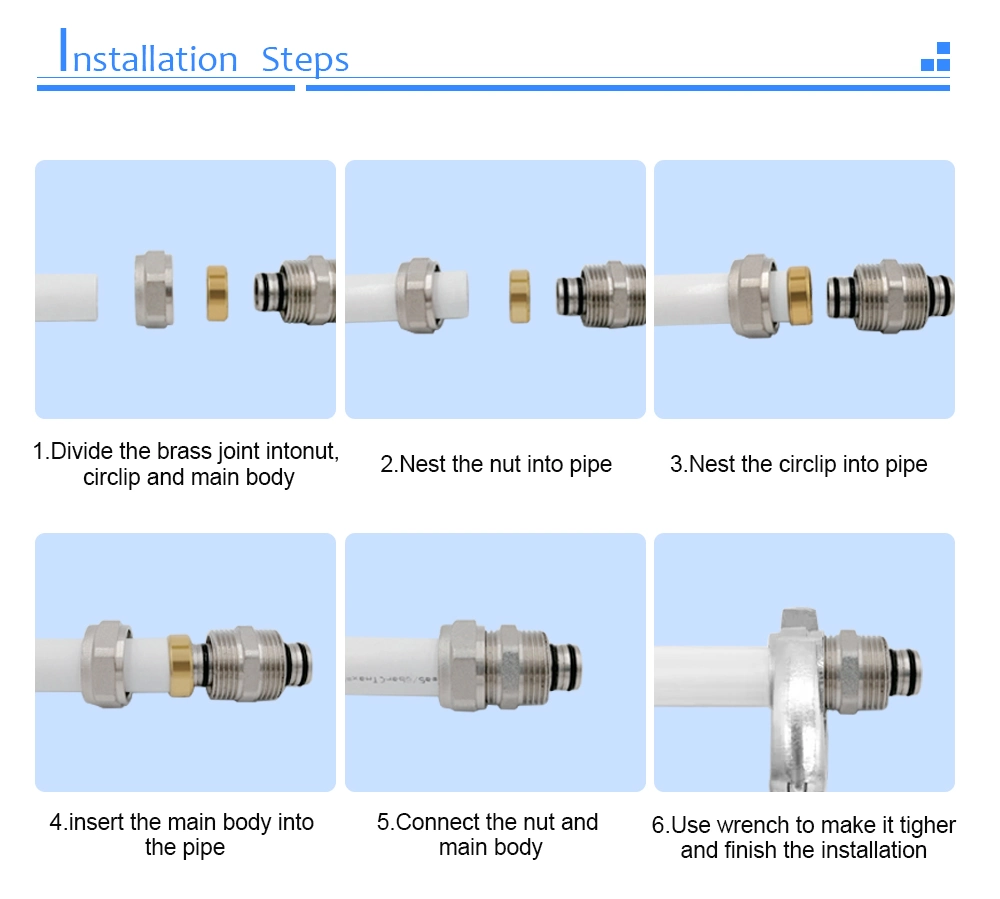

6. Simple installation: PEX aluminum-plastic pipe can be installed through simple welding and joints, and it is also very convenient for maintenance and replacement.

6. Simple installation: PEX aluminum-plastic pipe can be installed through simple welding and joints, and it is also very convenient for maintenance and replacement.

| Product Name | Pex Al Pex Pipe |

| Color | Natural / Customized |

| Working Pressure | 0.86mpa-1.25mpa |

| Size | 16-32mm |

| Material | Pex + Aluminium |

| Usage | Hot & cold water system/floor heating system/gas system |

| Performance | Good Flexibility, Easy To Bend |

| Certification | Iso 15875-2-2003, Gb/t 18992.2-2003 |

| Health Guarantee | The Interior Is Smooth, Not Easy To Corrode, And Does Not Form Scale |

| Work Temperature | -20ºC-120ºC |

| Feature | Corrosion Resistant |

| Connection | Brass Fittings |

| Package | Carton +opp Bag |

| Material: | PEX | PEX | |

| The type of the crosslinking | B | b | |

| The degree of crosslinking | ≥65% | ≥65° | the recommended level: 75° |

| The granules class | ≥PE80 | ≥PE80 | |

| The max. working temp. | 95ºC | .+95°C | |

| The min. Working temp. | '-40ºC | .-40°C | |

| Working pressure | <1.25 | ≤1,25 Mpa | |

| Bursting Strenght for +95°C | 5.98 MPA | ≥45 bar | |

| Resistance to delamination | / | ≥ 9 N/mm | acc. DVGW W 542 befor and after conditioning |

| Tensile strenght cone | 2400-3320N | acc. DVGW W 542 | |

| Thermal durability | 135ºC | acc. ISO 21003-2 | |

| Other requirements | acc. ISO 21003 | ||

| Marking | / | acc. customer requirements, minimum: every 1 meter | |

| Thermal conductivity | 0.45W/(M.K) | 0.45W/mK | |

| Thermal Expansivity | 0.025mm/(M.K) | 0,025 mm/mK | |

| Bend radius | ≥5D | 5xD ext. | |

| Paking | / | acc. customer requirements |

| Pipe size | Outer diameter | wall thickness | aluminium thickness |

| 16x2,0 | 16 +0,3 | 2,0 +0,13/-0,03 | 0,2 +0,01 |

| 20x2,0 | 20 +0,3 | 2,0 +0,13/-0,03 | 0,22 + 0,01 |

| 25x2,5 | 25 +0,3 | 2,5 +0,15/-0,03 | 0,25 +0,01 |

| 32x3,0 | 32 +0,3 | 3,0 +0,15/-0,03 | 0,30 +0,01 |