- Overview

- Product Description

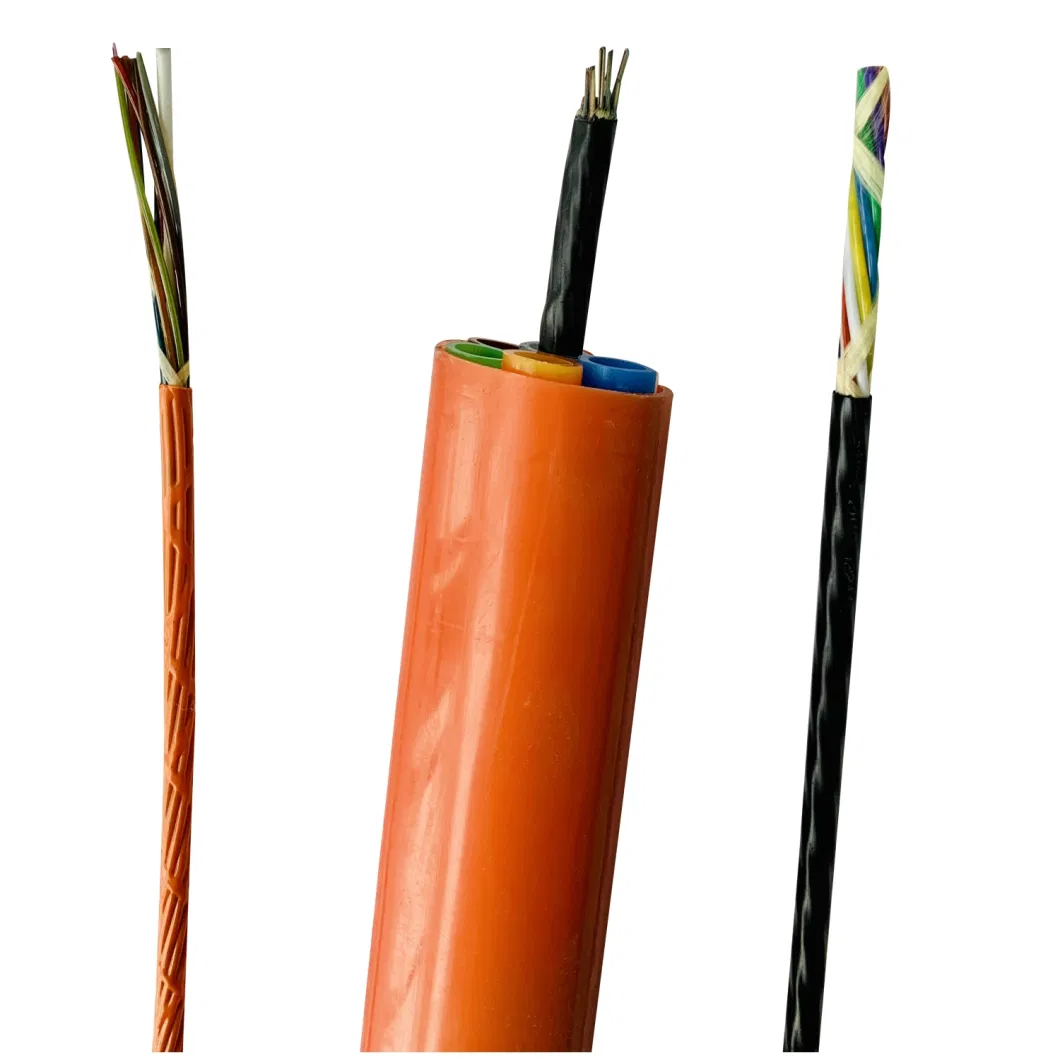

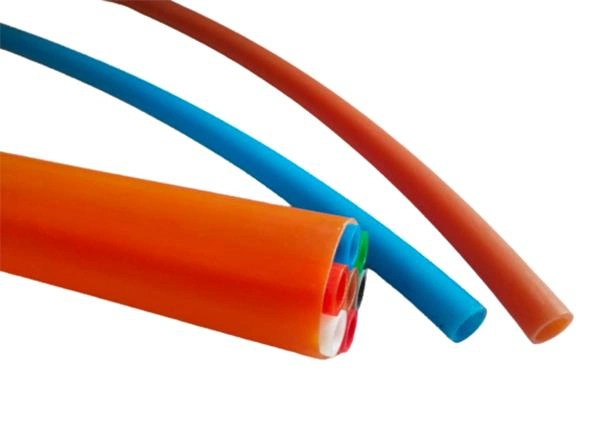

- Detailed Photos

- Features and Benefits:

- Packaging & Shipping

- FAQ

- Related Products

Basic Info.

Packaging & Delivery

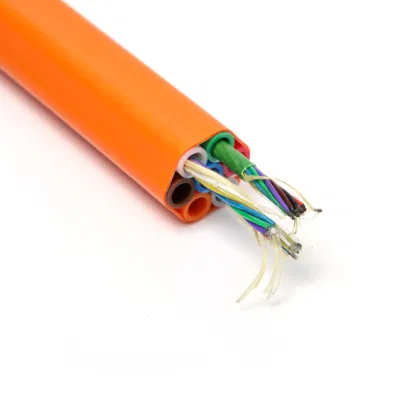

Product Description

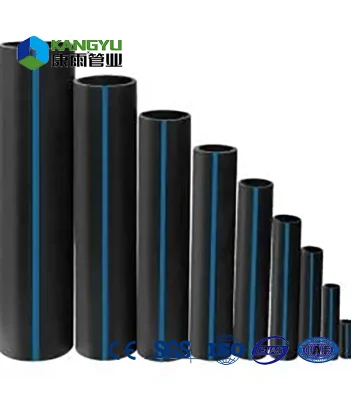

HDPE Micro duct for direct installation into the ground or installation into the protective sleeve, Microduct is a new high-tech products in reducing the cost, easy construction conditions, exponentially enhance the value of existing underground pipeline capacity and resources, has a traditional pipe products irreplaceable advantages.

Application:

A bundle of micro-or mini-tubes(regular wall size) is surrounded by single thin HDPE sheath. The design makes the duct assemblies suitable for outdoor direct buried or other existing ducts or cable trays.The micro ducts are optimized for best cable blowing performance.

HDPE Microduct Specification:

| O.D. mm | I.D. mm | Thickness mm | SDR | Min. Ben Radius mm | Max. Tensile Strength | |

| N | KG | |||||

| 5 | 3.5 | 0.75 | 6.7 | 60 | 150 | 15 |

| 7 | 3.5 | 0.75 | 4.0 | 100 | 430 | 43 |

| 7 | 5.5 | 0.75 | 9.3 | 84 | 220 | 22 |

| 8 | 6 | 1.0 | 8.0 | 80 | 330 | 33 |

| 10 | 8 | 1.0 | 10.0 | 120 | 420 | 42 |

| 12 | 8 | 2.0 | 6.0 | 144 | 935 | 93.5 |

| 12 | 10 | 1.0 | 12.0 | 144 | 515 | 51.5 |

| 14 | 10 | 2.0 | 7.0 | 200 | 1010 | 101 |

| 14 | 12 | 1.0 | 14.0 | 200 | 550 | 55 |

| 16 | 12 | 2.0 | 8.0 | 300 | 1150 | 115 |

| 16 | 14 | 1.0 | 16.0 | 300 | 630 | 63 |

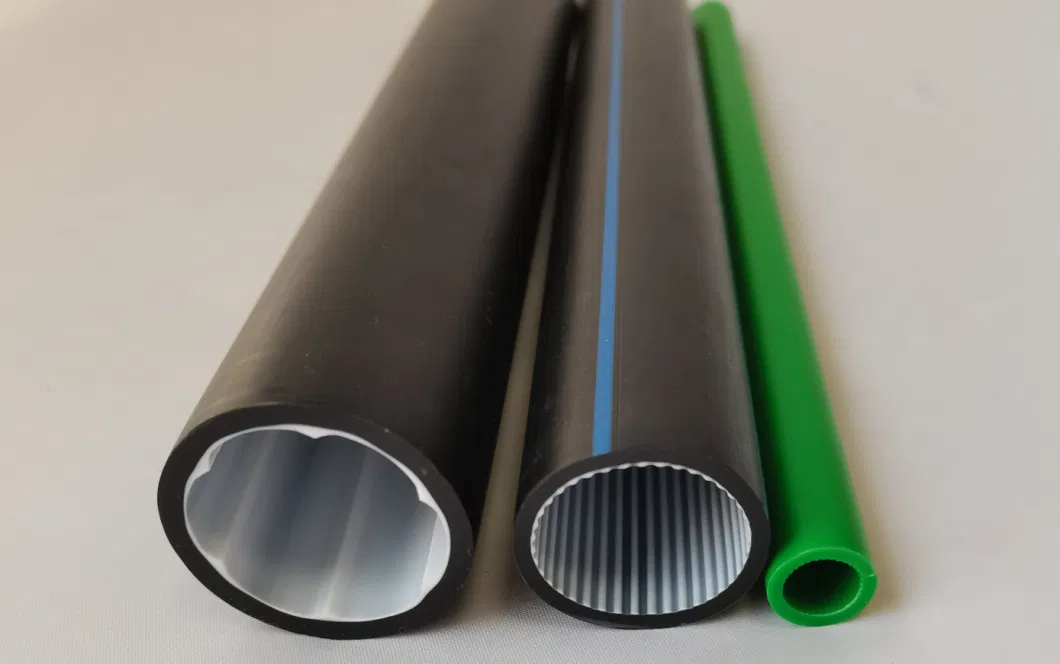

Characteristic:

1.Permanant solid silicon lubricant layer in the inner wall.

2.Longitudinal ribbed inner wall of microduct to further reduce the friction coefficient of duct so as to be beneficial to cable blowing.

3.Maximum accommodation is 288C micro cable.

4.Can be placed into the existing pipe system to fulfill the pipe hole expansion.

5.Reduce the construction cost, and shorten the construction period.

Advantages:

1. Low friction: inner layer of ducts is duly silicon coated which minimizes the friction between optical fibre cables and the duct during the process of blowing the cable into the ducts, thus providing smooth installation of optic fiber cable in the duct without damaging the cable fibres.

2. Green Initiative: HDPE silcon core pipe is a recycled material, environment friendly.

3. Corrosion resistance: PE belongs to inert materials, can resistance to various chemical media.

4. Good flexibility: high resistance to impact. Resistance to earthquake and twisting.

5. Non-leakage:HDPE silicon core pipe be connected by Electric welding.

Packing Details : wooden drum, standard safe package or according to customer's request.

Delivery Details : 3-7 days after payment confirmed(depend on the quantity)

(Maybe you will have some questions as below)

1.About the price?

Re: We usually quote within 6 hours after we confirm the technical data of your products.

Re: We accept L/C,T/T,Western Union,MoneyGram,PayPal etc.

3.What are your terms of payment?

Re: 30% in advance,and 70% before shipment

4.How to ship the items to me?

Re: Courier(DHL,TNT,FEDEX,UPS,EMS),Airfreight,Ocean Ship are available.

5.How long is your delivery time?

Re:The general delivery time is 5-7 days after order confirmed,it depends on the order quantity.

We supply fiber optic cable and related accessories, if you're interested in our products, please send us an inquiry!