- Overview

- Product Parameters

- Certifications

- Packaging & Shipping

- Company Profile

- FAQ

Basic Info.

Packaging & Delivery

To be negotiated ( > 100000 Meters)

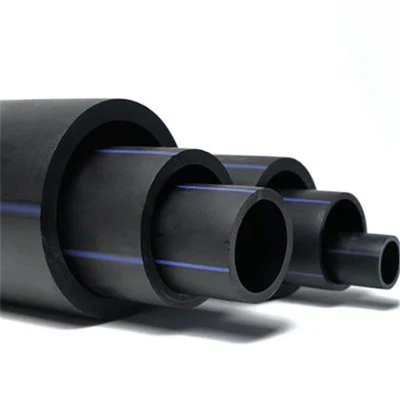

Product Description

Raw material:PE80 or PE100

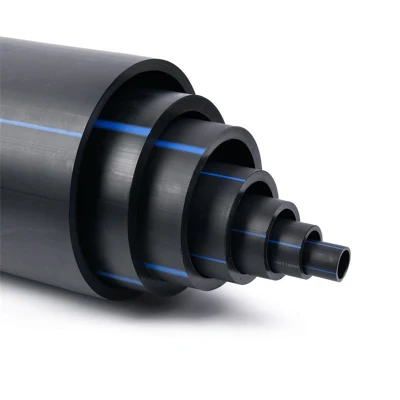

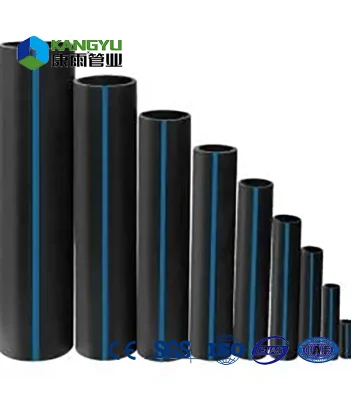

Outer diameter size:DN20mm-DN1600mm

working pressure for PE80 pipe:

SDR33(0.4MPA),SD21(0.6MPA),SDR17(0.8MPA),SDR13.6(1.0MPA),SDR11(1.25MPA)

working pressure for PE100 pipe:

SDR26(0.6MPA),SDR21(0.8MPA),SDR17(1.0MPA),SDR13.6(1.25MPA),SDR11(1.6MPA)

Size and Technic Standard:

GB/T13663-2000 and GB/T13663.2-2005

safety and health standard:

GB/T17219-1998

Specification: OD20mm-OD2500mm

Pressure: 0.32Mpa-2.0Mpa

Length: 5.8m/11.9m or as required

Standard: GB/T13663-2000, ISO4427-1:2007

Material: High Density Polyethylene

Color: Black or as required

Advantages of HDPE pipe:

1.High density polyethylene(HDPE) pipes

2.Light weight

3.Does not corrode

4.Resistant to chemical fertilizers and herbicides

5.Non toxic and odorless

6.Resistant to harsh climate

7.Up to 50 years' durability

8.Resistant to deformation

9.Smooth interior structure, low friction losses

10.Low labor coat for handling and installing

11.Reliable performance and easy maintenance

| PE100 | 0.4MPa | 0.5MPa | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa |

| Outside Diameter | PN4 | PN5 | PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 |

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | SDR7.4 | |

| Wall Thickness (en) | |||||||||

| 20 | - | - | - | - | - | - | 2 | 2.3 | 3 |

| 25 | - | - | - | - | - | 2 | 2.3 | 3 | 3.5 |

| 32 | - | - | - | - | 2 | 2.4 | 3 | 3.6 | 4.4 |

| 40 | - | - | - | 2 | 2.4 | 3 | 3.7 | 4.5 | 5.5 |

| 50 | - | - | 2 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | - | - | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | 8.6 |

| 75 | - | - | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | 10.3 |

| 90 | - | - | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | 12.3 |

| 110 | - | - | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | 15.1 |

| 125 | - | - | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | 17.1 |

| 140 | - | - | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | 19.2 |

| 160 | - | - | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | 21.9 |

| 180 | - | - | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | 24.6 |

| 200 | - | - | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | 27.4 |

| 225 | - | - | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | 30.8 |

| 250 | - | - | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | 34.2 |

| 280 | - | - | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | 38.3 |

| 315 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 | 43.1 |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 | 48.5 |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | 54.7 |

| 450 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | 61.5 |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | - |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | - |

| 630 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 | - |

| 710 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 | - |

| 800 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 | - |

| 900 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | - | - |

| 1000 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | - | - |

| 1200 | 29.4 | 36.7 | 45.9 | 57.2 | 67.9 | 88.2 | - | - | - |

| 1400 | 34.3 | 42.9 | 53.5 | 66.7 | 82.4 | 102.9 | - | - | - |

| 1600 | 39.2 | 49 | 61.2 | 76.2 | 94.1 | 117.6 | - | - | - |

| Item | Technical Index | |

| Density (g/cm³) | 0.941~ 0.965 | |

| Black Carbon Content | 2 ~ 2.5% | |

| Vica Softening Point (ºC) | ≥126 | |

| Melt Flow Rate, 190ºC, 5kg (g/10min) | 0.2 ~ 1.4 | |

| Longitudinal Shrinking Rate | ≤3% | |

| Elastic Modulus (Mpa) | 600 ~ 900 | |

| Coefficient Of Linear Expansion (mm/mºC) | 0.16 ~ 0.20 | |

| Oxidation Induced Time , 200ºC (min) | ≥20 | |

| Extension Rate Break | ≥350% | |

| Hydraulic test for PE100 pipe | 20ºC,100h, Circumferential Stress 12.4Mpa | No leakage/no rupture |

| 80ºC,165h, Circumferential Stress 5.5Mpa | No leakage/no rupture | |

| 80ºC,1000h, Circumferential Stress 5.0Mpa | No leakage/no rupture | |

| Hydraulic test for PE80 pipe | 20ºC,100h, Circumferential Stress 9.0Mpa | No leakage/no rupture |

| 80ºC,165h, Circumferential Stress 4.6Mpa | No leakage/no rupture | |

| 80ºC,1000h, Circumferential Stress 4.0Mpa | No leakage/no rupture | |

Product Description

HDPE pipe is a perfect solution for municipal engineering system and urban water supply and drainage system.HDPE pipe adopts high-quality original PE100 or PE80 raw material with the size range of DN 20-2500mm,

and the performance conforms to ISO4427 standard and other national certification standards.

HDPE pipes for water supply can be manufactured with different rated pressures mainly:

SDR26/0.6MPa, SDR21/0.8MPa, SDR17/1.0MPa, SDR13.6/1.25MPa, SDR11/1.6MPa, etc.

Features

Our HDPE pipe for water and sewer is manufactured for excellent performance and a long life expectancy.1. High resistant to corrosion and weather, recent studies conclude it will last at least 50 years.

2. Its light weight and flexibility make it easy to install, eliminating the need for fittings required with directional changes,

and make it highly suitable for use in earthquake prone areas.

3. Its high-strength walls give it the highest PE pressure rating, outstanding resistance to SCG and increased resistance to rapid crack propagation.

4. The increased working stress rating of high-performance PE resin material makes it a superior choice over

steel or ductileiron pipe, especially for the large diameter pipe sizes.

HEBEI Shentong Plastic Industry Co., Ltd. Was established in 2003, which is an enterprise concentrating

manufacturing PLASITC pipes and fittings.

The leading products are Fosite Brand PP-R PIPE AND FITTING,

HDPE PIPE AND FITING, UPVC pipe and fittings,

PE-RT, PEX pipes & fittings and plastic tubing welding equipment. It has advanced automatic machines.

We pursuit the quality is the first and the service is also important. Shentong has passed ISO9001, ISO4001.

We have our own test lab for quality control. Our brand Forsite is famous in home and overseas market.

SHENTONG promises: Reasonable price, fast delivery and satisfactory service.

Hope to cooperate with more customers for mutual development and benefits, warmly welcome potential buyers to contact us.

1.Where is your factory located in?

Our factory located in SHIJIAZHUANG City.

2.Can you provide us some samples for testing?

Ok, no problem . To enable you have a good understanding of our product quality,

Sample is available for you testing.

3.Which kind of payment terms you usually do?

We usually do T/T, But L/C is no problem.

4.How about the delivery time?

For small order, 15 days is ok,large order maybe will 30 days.

5.Do your factory can provide OEM Services?

Yes, we can produce product by customers' special requirement.

We have many OEM Customers from Europe and Southeast Asia