Basic Info.

Model NO.

Tyton pipe fitting

Technics

Casting

Certification

ASME, ANSI, DIN, JIS, BS, GB, GS, KS, API

Color

Blue

Name

Push-in Joint Pipe Fittings

Test

100% Water Pressure Test

Working Pressure

40bar

Fluid Temperature

0-50, Excluding Frost.

Gasket

Rubber E.P.D.M./NBR/SBR

Fitting

Ductile Iron Grade 500-7/ 450-12

Quality Control

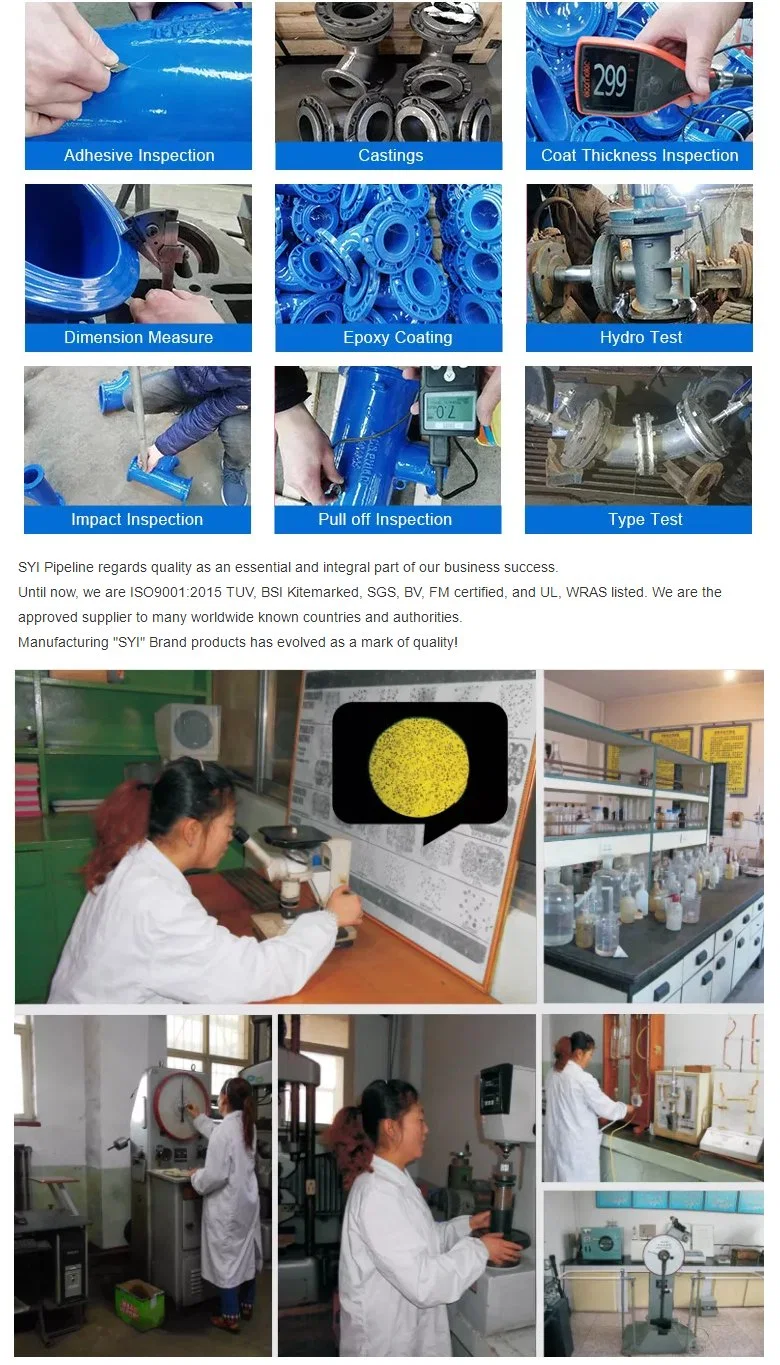

Strict Inspection as Per Standard

Surface Treatment

Powder Coating/Fbe

Transport Package

Standard Export Package or as Per Your Requirement

Specification

ISO 2531 EN 545 EN598

Trademark

SYI

Origin

China

Production Capacity

1500 Tons Per Month

Product Description

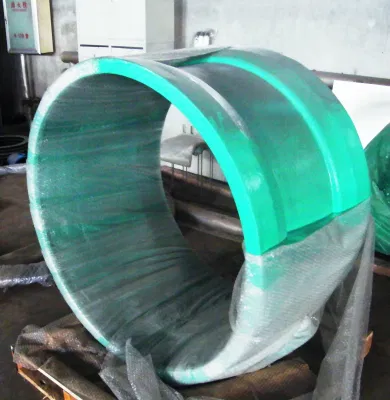

ISO 2531 EN 545 EN598 Ductile Iron Tyton Push-in Joint Socket Pipe Fittings

Description

Push-in Flexible Joint (Tyton) Fittings can be assembled by pushing the spigot through the gasket in the socket of the mating component,and permits significant angular deflextion both during and after installation and which can accept a light offset of the centreline.

| Name | Push-in Flexible Joint (Tyton) Fittings |

| Material | Fitting:Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083. Gasket:Rubber E.P.D.M./NBR/SBR in accordance with EN 681.1 |

| Working Pressure | 40 Bar |

| Fluid Temperature | 0°C-50°C, excluding frost. |

| Coating | External Coatings: zinc coating +bitumen painting;liquid epoxy resin painting;epoxy applied by FBE;according to customers' requirements. Internal Coating: cement mortar lining;liquid epoxy resin painting;epoxy applied by FBE;according to customers' requirements. |

| Reference Rules | Dimensions and testing in accordance with ISO 2531/EN 545 |

Package

Packing: Different package upon your request,like wood cases&pallets,ply-wood crates&pallets,steel crates&pallets and etc.

Quality Control

Company

Company

Welcome to send us an inquiry for more details and price!!!