- Overview

- Product Description

- Hot Products

- Company Profile

- Packaging & Shipping

- FAQ

Basic Info.

Model NO.

KDPE

Customized

Customized

Condition

New

Produced Pipe Diamater Range

16-630mm

Production Speed

35m/Min; 60m/Min

Trademark

KAIDEMAC

Origin

Weifang, China

HS Code

8477209000

Production Capacity

200 Sets/ Year

Product Description

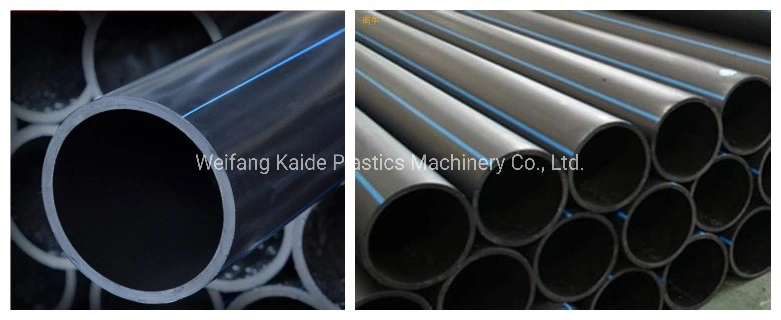

HDPE Pipe Production Line

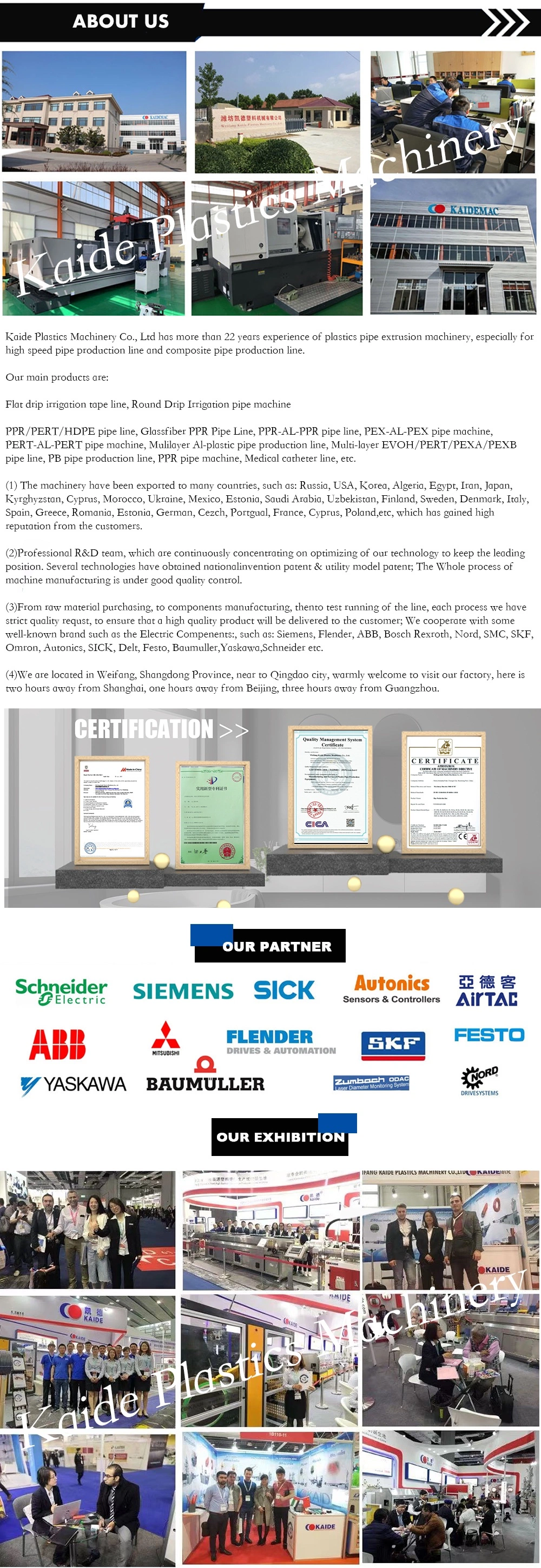

KAIDE factory has focused on plastic pipe extrusion technology for more than 20 years, especially for high speed pipe line and multi-layer pipe line.

For small diameter HDPE pipe from 20mm-63mm, the production speed can reach to 60m/min, in order to increase the production efficiency, reduce production cost, such as labor, electric and water consumption etc.

Maximum HDPE pipe diameter we can made is up to 630mm. For big diameter, the extrusion line can be mult-layer coextrusion type, like two layer co-extrusion or 3 layer co-extrusion.

Gravimetric material dosing system can be equipped to save raw material, shorten start up time, and increase pipe quality level etc.

Technical Data:

| Line Model | Screw Diameter | L/D | Production Scope | Line Speed or Output |

| KDPE-63 I | 65mm | 33:1 | 20-63mm | 15m/min; 90kgs/h |

| KDPE-63 II | 60mm | 36:1 | 20-63mm | 35m/min; 250kgs/h |

| KDPE-63 III | 75mm | 36:1 | 20-63mm | 60m/min, 320kgs/h |

| KDPE-160 | 75mm | 36:1 | 75-160mm | 320kgs/h |

| KDPE-315 | 75mm | 36:1 | 110-315mm | 420kgs/h |

| KDPE-450 | 75mm | 36:1 | 200-450mm | 600kgs/h |

| KDPE-630 | 90mm | 36:1 | 315-630mm | 800kgs/h |

1)Special designed high efficient five-section type screw and barrel, ensuring the rapid plasticizing & dispersion effect, and realizing high speed production.

2)Gravimetric material feeding system is to control material feeding according to pipe parameter & line production speed, to get high qualified pipe with constant weight per meter. It's also have other benefits, such as shortening start-up time, saving raw material, simplifying operation.

3)Spiral pressure-storage die head, ensuring the stability of high speed extrusion and produced pipe quality.

The die head is designed different as per pipe pipe structure and diameter range, like high speed extrusion die head, two layer co-extrusion die head or three layer -co-extrusion die head.

4)Different type pipe coiler is equipped as an option, like coiler for 16-32mm or coiler for 20-63mm, or even big up to 110mm HDPE pipe coiling.

5)SIEMENS PLC programmable computer control system, which could ensure the whole line high-speed synchronous control and its stable & reliable running.

We are manufacturer.

2. What price terms you offer?

FOB, CIF, EXW and other price terms based on your kind request.

3.Is installation and stuff training available from you?

Yes, our engineers will guide machine installation and train your workers.

4. How long will I receive the quotation?

Once we know the raw material, final product dimension and the special requirements, we will provide you a detailed quotation within 24 hours.

5. How do I get response quickly?

If you send inquiry to contact us, we promise to reply to you within 8 hours!