- Overview

- Product Description

- Product Parameters

- Detailed Photos

- Figure Plane

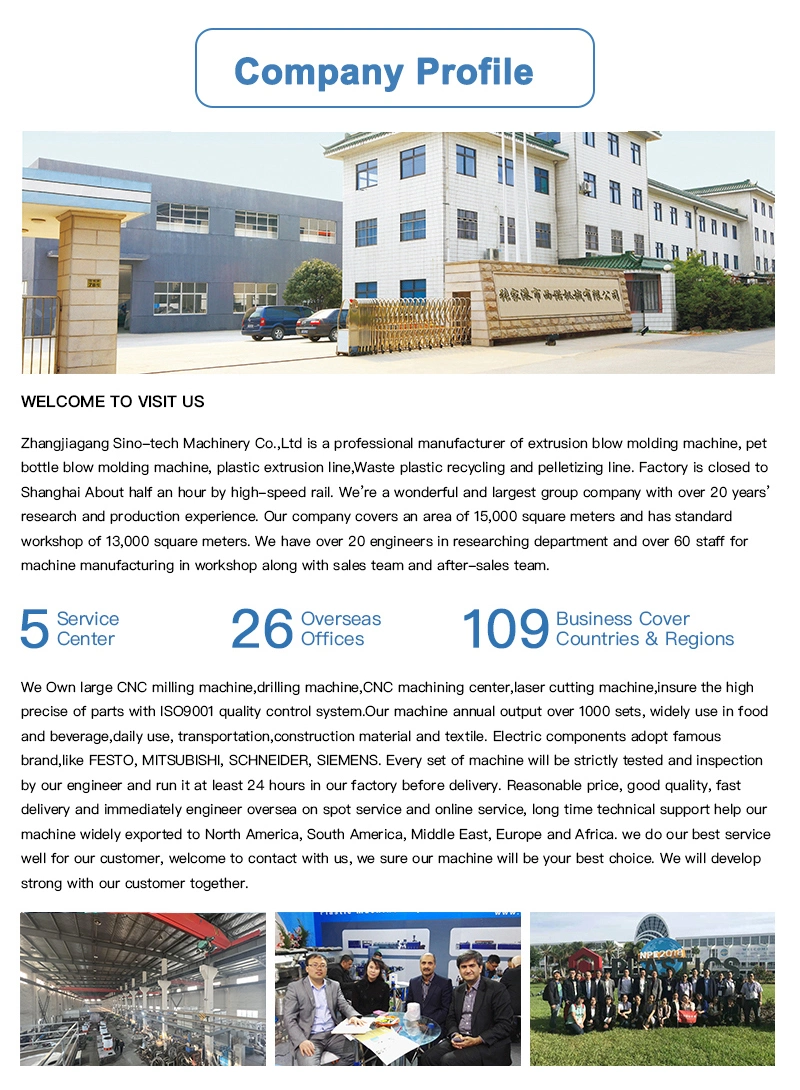

- Company Profile

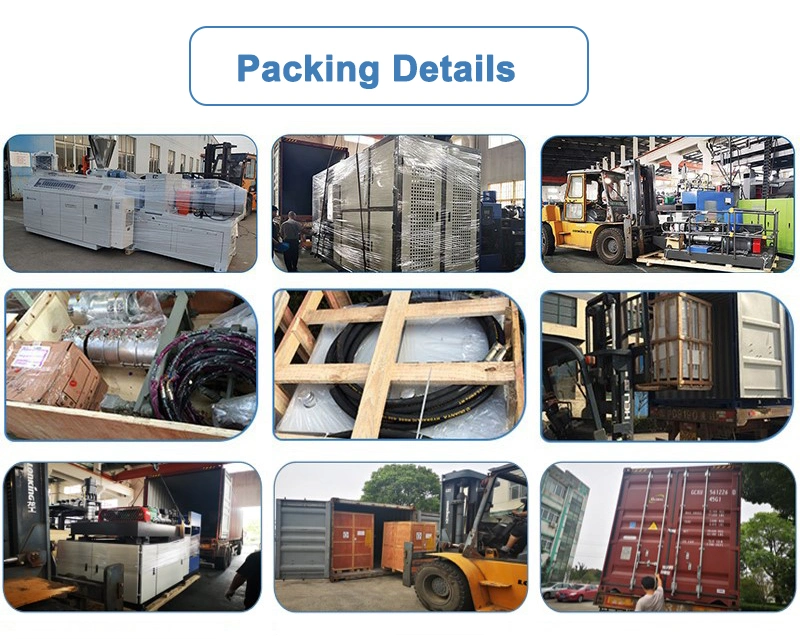

- Packaging & Shipping

Basic Info.

Packaging & Delivery

Product Description

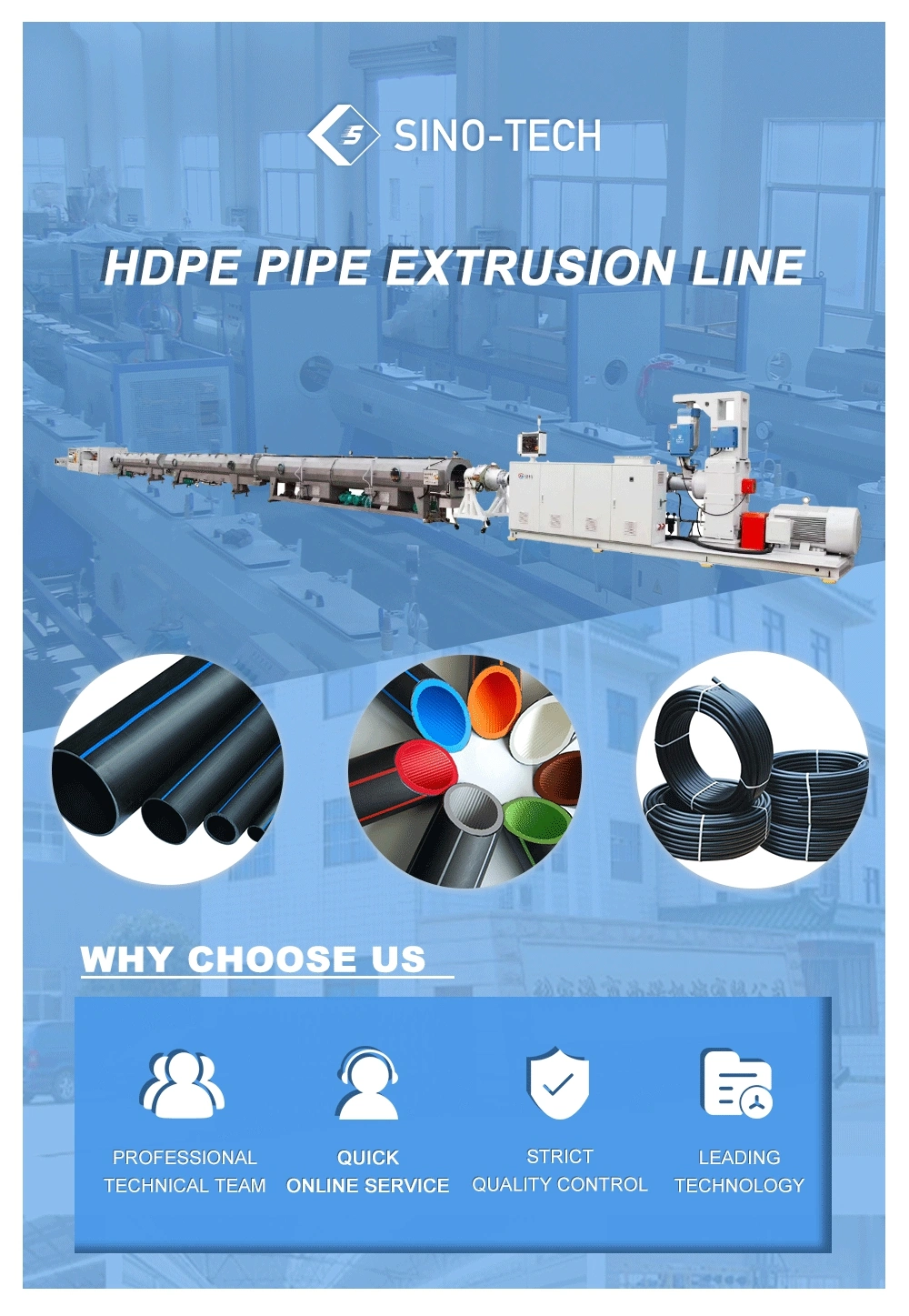

SINOTECH HDPE Pipe Extrusion Line

1. 25m/min of maximum lineal extrusion speed, big capacity and low power consumption, and achieved multi- layers co extrusion Unique design with 1-3 layers.

1. 25m/min of maximum lineal extrusion speed, big capacity and low power consumption, and achieved multi- layers co extrusion Unique design with 1-3 layers.2. Unique design (barrier,shearing and mixing zone) guarantees a uniformed plasticizing effect, and can reduce the pressure on the screw which guarantees a high speed and smart figuration, compact stable output capacity.

3.High torque gear box has a smart figuration, compact construction, low noise, high carrying capacity, high transmission efficiency can assure long-time trouble-free operation.

4. PVA(pipe air cooling system)die head largely increase the extrusion speed and decrease the cooling length of extrusion line, and improve quality of inner pipe

5.Intelligent PLC controlling surface.

6. interface make the operation easily and conveniently.

7. Chip-free cutter ensuing flat and smooth cutting surface of pipe.

HDPE pipe Extrusion Line Application:

Agricultural Irrigation Water Pipe&Sewage Drainage pipe&Gas supply Pipe

Production Flow:

Material →Color Mixer →Material Feeding →Single Screw Extruder →Extrusion Mould & calibrator → vacuum Calibration Cooling Tank → Spray Cooling Tank →Printer → Haul-off Unit →cutter →stacker or Coiler

Twin Screw Extruder is applicant for PVC powder material, with different mould and downstream equipment; the plastic extruder can produce pipe, profile, plate&sheet, and pelletizing. The extruder features in good plastic extrusion, good plasticization, even melting, high output capacity, wide application and reliable stability, specially designed gearbox and distributor and reinforced thrust bearing realize large transmission torque and long operation time. Electrical control system: Siemens PLC/PCC auto control system or RKC temperature control, and ABB Invert/transducer, Siemens contactor, and several alarm system

| Conical Twin Screw Extruder | |||||

| Specification/Model | SJSZ45/90 | SJSZ51/105 | SJSZ65/132 | SJSZ80/156 | SJSZ92/188 |

| Screw diameter | 45/90 | 51/105 | 65/132 | 80/156 | 92/188 |

| Ratitional speed of screw | 1-45rpm | 1-45.5rpm | 1-38rpm | 1-36.9rpm | 1-34.5rpm |

| Main motor power | 15kw | 22kw | 37kw | 55kw | 110kw |

| Barrel heating power | 9.6kw | 11.5kw | 24kw | 36kw | 88kw |

| Production capacity | 70kg/h | 120kg/h | 250kg/h | 360kg/h | 1000kg/h |

| Net weight | 2500kg | 3000kg | 4000kg | 5000kg | 5500kg |

Single Screw Extruder is mainly used to process PP, PE, PP-R, ABS and other plastics. Equipped with auxiliary machines, it can manufacture profile, pipes, sheets and other plastic products and granulation. This Single Screw Extruder has the advantage of simple production technological process, high output, stable quality and low cost.

| Single Screw Extruder | |||||

| Model | L/D | Output | Speed of Screw Rotationl | Power | Center Height |

| SJ-30 | 10-33 | 10-25kg/h | 20-120r/min | 3-5.5kw | 1000mm |

| SJ-45 | 10-33 | 10-35kg/h | 20-120r/min | 7.5-18.5kw | 1000mm |

| SJ-50 | 10-33 | 20-80kg/h | 20-120r/min | 22-37kw | 1000mm |

| SJ-65 | 10-33 | 80-150kg/h | 20-120r/min | 37-55kw | 1000mm |

| SJ-75 | 10-33 | 120-280kg/h | 20-120r/min | 55-90kw | 1000mm |

| SJ-90 | 10-33 | 150-450kg/h | 20-120r/min | 90-160kw | 1200mm |

| SJ-120 | 10-33 | 300-600kg/h | 20-120r/min | 160-260kw | 1200mm |

| SJ-150 | 10-33 | 450-700kg/h | 20-120r/min | 260-315kw | 1200mm |

01 Screw Extruder

a. Material of screw:38CrMoAl

b. Heating zones:4

c. Heating Mode:Cast Alumina+Stainless

d. Steel Covering e.Inverter:ABB

f. Contactor:Schneider

g. Relay:Omron

h. Temperature:Omron

Extrusion head with spiral structure,make sure the melt insidedistributed evenly so as to achievebest plasticization.

Calibrator design with water ring which is easy to clean to achieve better cooling and then fast forming.

Advanced pipe line layout design and adjustable spray angle for better cooling effect, dense pipe line in the first zone for fast cooling.

For different pipe size and different speed requirement,we developed different kinds of haul-offunit.Optional to choose multi-caterpillar haul-off unit with different speed range.

Cutter is controlled by servo motor to make sure precise cutting length.

a. Motor Power:2.2kw

b. Material of Blade:Crsi

c. Synchronous speed :1-12m/min

d. Control:PLC

e. Aluminum "HALF"clamps

a.Length:5000mm

b. With screw to adjust the height range :0-180mm

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support .

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees.

Q: What's the advantage of SINOTECH?

We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time