- Overview

- Packaging & Shipping

- Company Profile

Basic Info.

Product Description

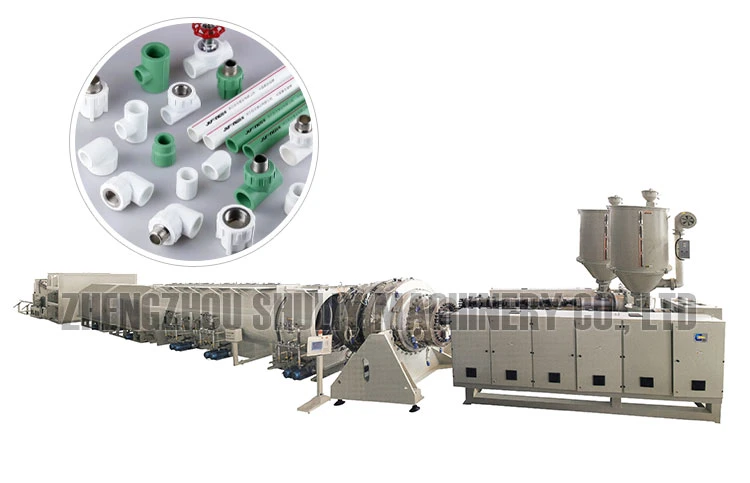

High Quality Plastic PE Pipe Extrusion Production Line for Sale Product Description20~63mm PPR PE HDPE Pipe Tube Processing Extrusion Manufacturing Machine Line Factory

Product Description20~63mm PPR PE HDPE Pipe Tube Processing Extrusion Manufacturing Machine Line Factory

The PPR Pipe Extrusion Line/HDPE Pipe Processing Machine/PE Pipe Tube Manufacturing Machine can be used for

HDPE large diameter gas and PPR water pipes, with excellent stiffness and flexibility, heat resistance, aging resistance,

high mechanical strength,environmental stress cracking resistance, creep resistance, hot link, etc. Therefore, the HDPE

PE Silicon Core Pipe Making Machine is the preferred gas and water pipe for the pipeline system between the city and the

suburbs, and thelarge-diameter HDPE pipe line began to play a very important role in the urban water supply and gas supply

system.

| Name | Quantity/Set | Description |

| High Efficiency Single Screw Extruder | 1 | Motor, reducer, screw, barrel, automatic drying and feeding machine, electric control cabinet |

| Single screw co-extrusion color line machine | 1 | Motor, reducer, screw, barrel, electrical appliance |

| Vacuum Sizing Machine | 1 | The setting table is equipped with a two-way quick-change filter system |

| Spray cooling tank | 1 | Applicable pipe diameter Φ20-Φ63mm Sink length 6000mm Pump power 4kw × 1 set water temperature controller water filter |

| belt tractor | 1 | Traction motor power: 1.1kw*2 sets, speed regulation mode: frequency conversion speed regulation (ABB), number of belts: 2 crawler traction, belt adjustment mode: pneumatic pressing device, traction line speed: 1-10m/min Effective traction length: 1200mm, maximum traction force: 15KN, traction pipe diameter range: Φ20-Φ63mm |

| Chipless Cutter | 1 | Cutting method: chipless cutting, control method: programmable control, feed method: cylinder feed, revolution power: 1.5kw, applicable pipe diameter range: Φ20-Φ63, saw blade diameter (mm): Φ75, cutting speed: 6m/min |

| Turnover rack | 1 | 6 meters in length. stainless steel flap |

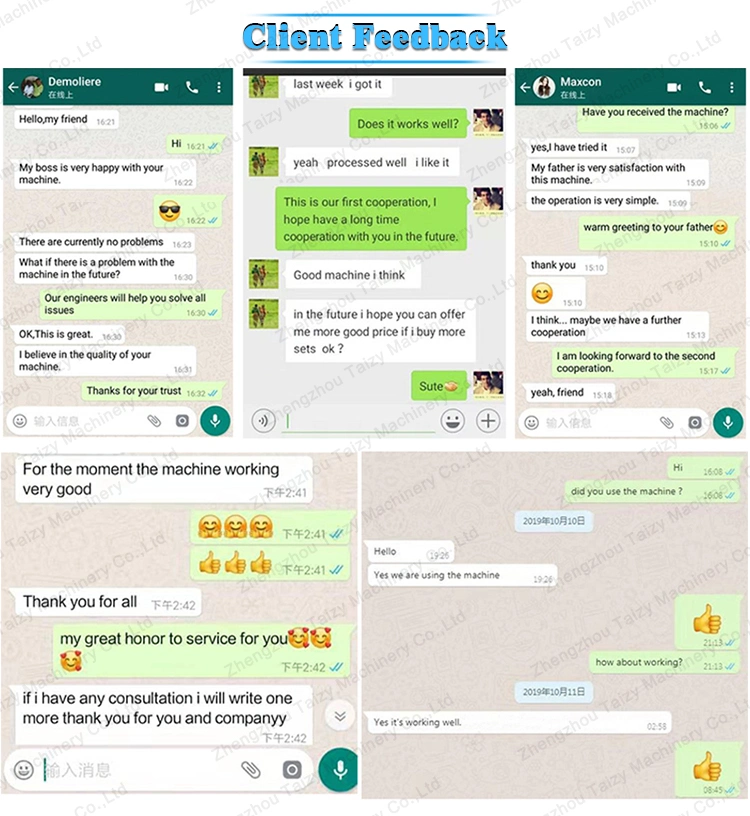

Q: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we

take a test on each piece of equipment before delivery.

Q: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service

team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment,

and operation training.