Basic Info.

Model NO.

HDPE P6006

Plastic Properties After Heated

Thermoplastic Plastics

Plastic Forming Method

Extrusion

Color

White

Raw Materials

Oil

Transport Package

PE Bag

Specification

25kg bag

Origin

Saudi Arabia

HS Code

3901200099

Production Capacity

2 Million Tons/Year

Product Description

Description:

P6006 is black compound high density (class MRS 10 - PE 100) Polyethylene with bimodal distribution of molecular mass. It is specifically designed for pressure Pipe applications. It provides excellent stress crack resistance properties (ESCR) combined with very good long term hydrostatic strength.

Applications:

P6006 Pressure pipes for drinking water, irrigation, gas distribution and waste water pipes. It is also recommended for manufacture of chemical liners and containers.

Packaging:

In 25kg bag, 26-28MT in one 40HQ.

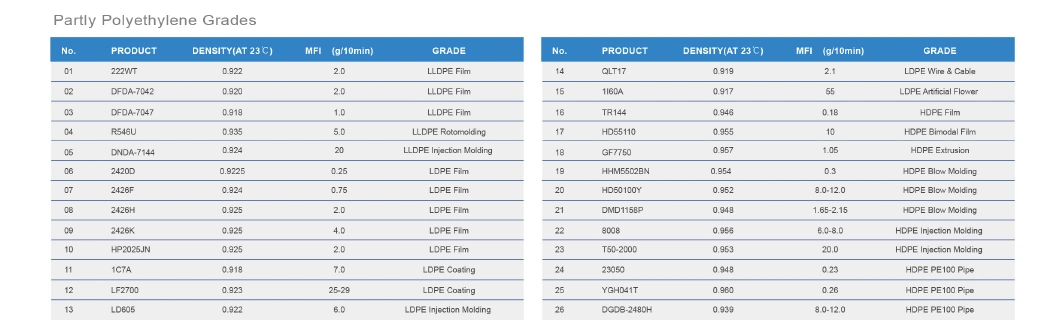

| No. | PROPERTIES | Unit | Value | Test Method |

| 01 | Melt Flow Rate | - | - | - |

| 02 | @ 190°C & 5 kg load | g/10 min | 0.23 | ISO 1133 |

| 03 | @ 190°C & 21.6 kg load | - | 6.2 | - |

| 04 | Carbon Black content | % | 2.25 | ISO 6964 |

| 05 | Density @ 23°C | Kg/m3 | 959 | ISO 1183 |

| 06 | Tensile Strength @ Yield(3) | MPa | 23 | ISO 527-2 |

| 07 | Tensile Elongation @ Yield(3) | % | 9 | - |

| 08 | Tensile Modulus(3) Charpy Impact Notched | MPa | 900 | |

| 09 | @ 23°C | kJ/m2 | 26 | ISO 179 |

| 10 | @ -30°C | - | 13 | - |

| 11 | Hardness (Shore D) | - | 63 | ISO 868 |

| 12 | Vicat Softening Point @ 50N (VST/B) | °C | 74 | ISO 306 |

| 13 | OIT (210°C) | Min | > 20 | EN 728 |