Basic Info.

Product Description

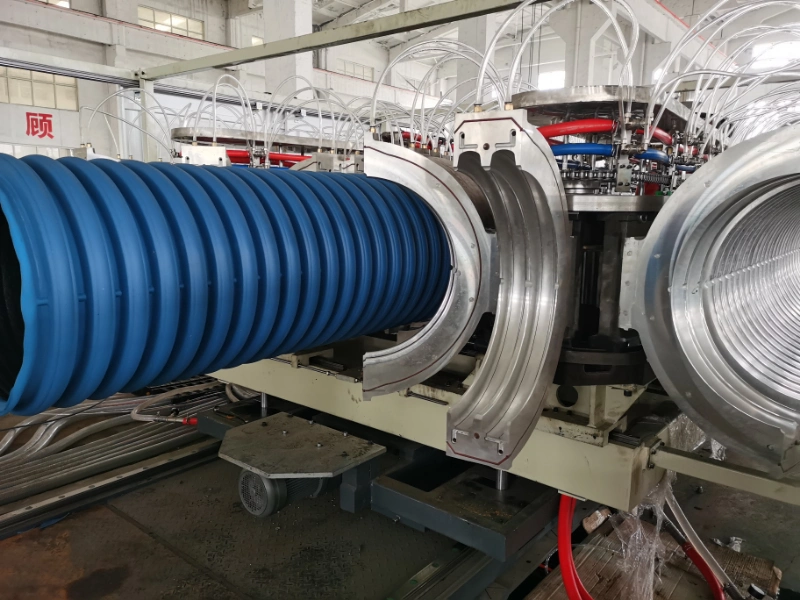

plastic corrugated pipe extrusion machine

doube wall plastic corrugation pipe line

Industry air conditioner accessory flexible corrugated portable extension exhaust air conditioner hose pipe extruder

Plastic corrugated pipe HDPE corrugated pipe extrusion machine

HDPE Industry Grade Corrugated Cable Pipe machine

Plastic corrugated pipe HDPE corrugated pipe

| Product material | HDPE |

| Working temperature | -40~110ºC |

| AD | AD18.5 |

| I.D. A | 14.3MM |

| O.D. B | 18.5MM |

| R | 40MM |

| Packing | 150m/roll |

| Features | good flexibility, resistance to distortion, good bending, can bear heavy load. |

| Usage | insert the wire and cable into the tube and use it in the type of fitting |

HDEP double wall corrugated pipe can be used for Pipeline drainage, sewage.

Mining engineering: double-wall bellows can be used for transport of ore, river silt, coal ash, mine air supply, ventilation,

drainage pipe; Communication engineering: used for communication cable casing, optical cable protection pipe, underground pipeline protection pipe, all kinds of power cable protection pipe

pipe wall.

Hot seller for HDPE Double-Wall plastic Corrugated flexible exhaust pipe OD75mm factory

1. Specification:

Diameter: 63/75/90/110/150mm

Pressure: S2 & S8

Color: green/ blue/ customized

OEM of sizes and colors are available.

Product Description

Application: This kind of pipe is high temperature resistance, anti-erosion, anti-abrasion and with high strength. The pipe can be used as oil pipe in automobile braking system, and for high temperature gas, chemical liquid transferring.

Advantage: Interplast Machinery's special designed screw and special structure mould can protect the screw and barrel from easy-abradion and give an easy forming process.

Material: PA, Tperature range:-40-115 centigrade.The product does not contain halide, antioil, anti-acid, anti-inflamation rate is HB(U94).The black color pipe is ultraviolet resistant.

Material: PP. Temperature range:-20-110centigrade,the productant is anti-oil, anti-alkali. The black color pipe is ultraviolate resistant.

Material; PE. Temperature range:-40-80centigrade,the product is anti-oil, anti-acid, anti-alkali. The black color pipe is ultraviolet resistant.

PE double wall corrugated pipe machine/Extrusion machine/ Production line

The Final Product Application:

Mainly used for conduit pipe, air delivery pipe, irrigation water seepage pipe, threading pipe, electrical wire jacket pipe, etc.

Brief introduction:

This machine use PE material to produce big diameter double wall corrugated pipe. The pipe has light weight,strong impact resisitant capability,high ring stiffness and corrosion resistance. So widely used in the cover of electrical wire undergrond,city water draining pipe and up-down water transporting pipe in construction etc.

Precision finishing of the forming machine,die and mould,the pipe is featuredwith good quality, Ring type twin knives of cutting machine guarantee the pipe cross-section vertical and plane.

2. Application:

1) Using food grade PE material, not easily deform, safe and environmentally friendly.

2) The surface and the inside are wavy, uniform in thickness and strong in impact resiatance.

3)Double-wall corrugated with a hollow structural layer, noise, no secondary noise. The loss of heat can be avoided, and the condensed water formed due to the temperature difference between hot and cold can also be reduced.

4) The HDPE fresh air duct has good flexbility. It reduces the direct use of the elbow in the ventilation duct durin the construction process. And the overall system improves the wind rate of the fresh air system.

Drainpipe, Water Supply Pipe, Threading Pipe, Wire and Cable Pipe, Agricultural Irrigation Pipe, Corrugated Pipe, Drainpipe, Water Supply Pipe, Threading Pipe, Wire and Cable Pipe, Agricultural Irrigation Pipe, Corrugated Pipe, Drainpipe, Water Supply Pipe, Threading Pipe, Wire and Cable Pipe, Agricultural Irrigation Pipe, Corrugated Pipe

The Industry's high-performance HDPE water pressure pipes are suitable for municipal and industrial transmission systems for potable water, sewer, drain, mining, irrigation, and reclaimed water. HDPE Pipe can be used in both water supply and water drainage.

Manufactured from High-Density Polyethylene (HDPE) and is intended for internal duct applications.

Our products are examined and tested to ensure to compliance with all the relevant standard specifications. The specified tests are all carried out in our laboratory. They are as follow:-

• High tensile strength to endure heavy external loads.

• Long-term strength for increased life and performance

• Lower installation cost

• Resistance to corrosive chemicals and aggressive soils

• Moisture proof and watertight when fusion welded

• No biological growth

• Low resistance to pulled-in cable

• Color coding for easy identification

Polyamide/PE/Nylon Flexible Cable Protection Conduit/Hose/Pipe extrusion line

Flexible Corrugated Extension Exhaust Hose Air Conditioner Vent Pipe

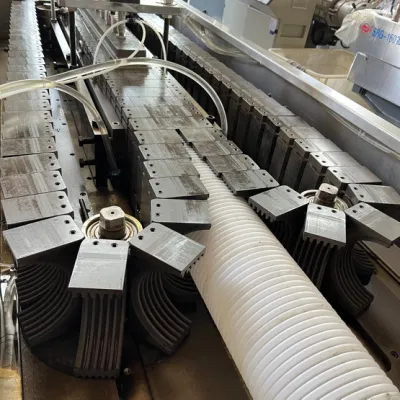

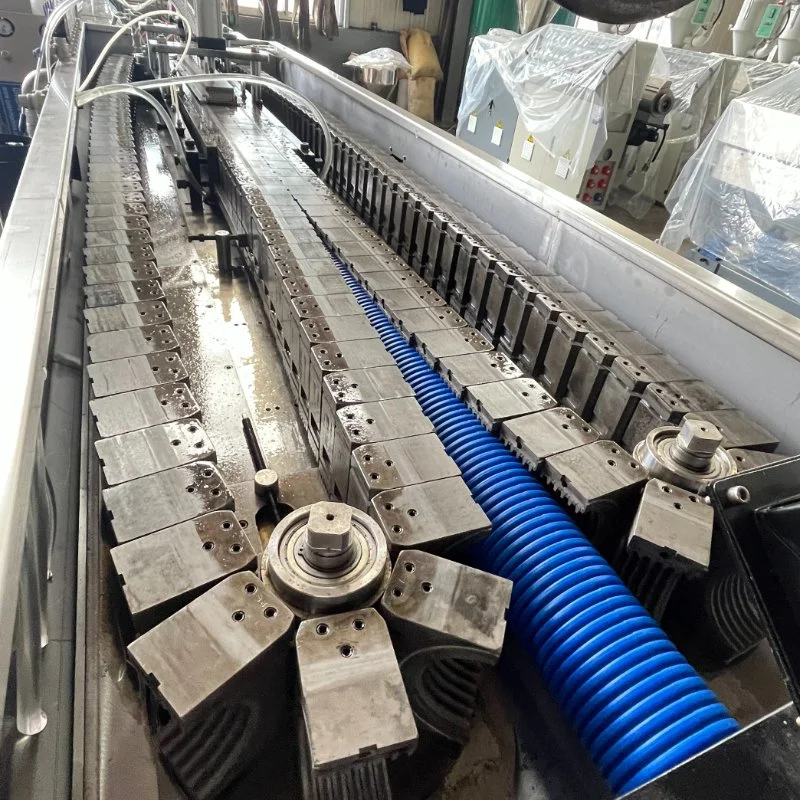

This double wall corrugated pipe making machine equipped with double layer spiral structure extrusion die head. Forming machine adopts vacuum forming type. This production line can produce PP,PE etc material small diameter double wall corrugated pipe continuously and stably. Plastic double wall corrugated pipe has the features of corrosion resistance, wear resistance, high strength, flexibility etc. Small diameter double wall corrugated pipe is widely used in cable sheathing, pipeline sheathing, fresh air pipeline and other fields.| Model | Pipe Diameter | Production Speed | Extruder Model | Motor Power |

| SJ-50 | 32-50 mm | 4-5 m/min | 65/30 & 55/30 | 30kw & 15kw |

| SJ-110 | 50-110 mm | 3-4 m/min | 65/33 & 65/30 | 37kw & 30kw |

| SJ-160 | 75-160 mm | 2-3.5 m/min | 75/30 & 65/30 | 45kw & 30kw |

Advantage of our Plastic DWC double wall corrugated pipe machine

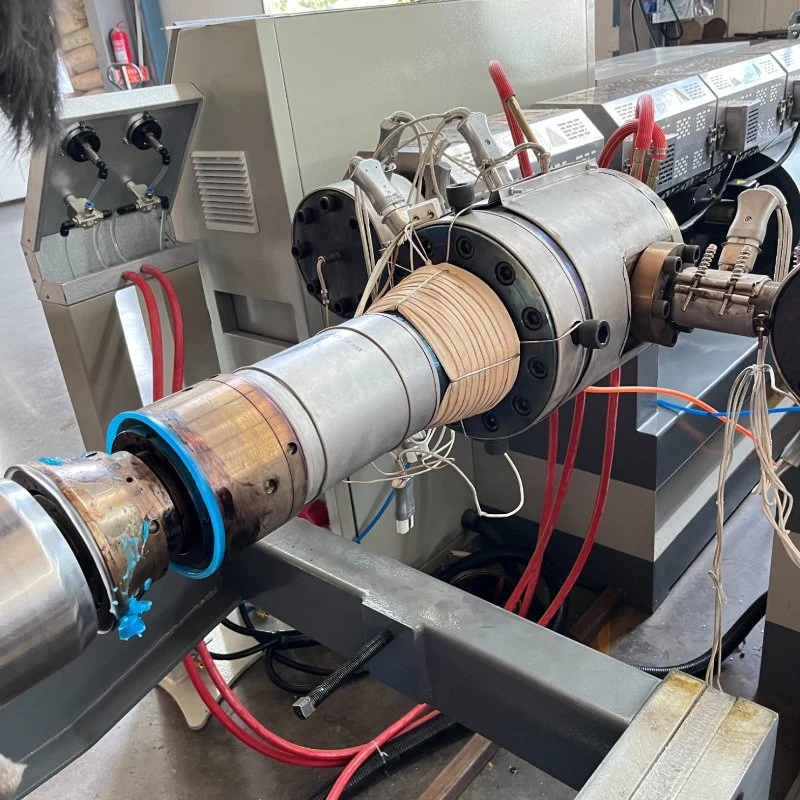

1. The main machine adopts special designed high efficiency screw which is specially used for polyolefin,it has the features of stable performance and high effiency.The machine has two independence extruders,which can realize both inside and outside layer with different material and colors.

2. Composite extrusion die head with specially helical structure to make the wall thickness unifom and stable production.

3. The forming machine has automatic power-off protection device.The forming machine an antomatically exit from the die head to avoid equipment failure in case of electrucity cut off suddenly.It also equipped with new type high transmitting ratio reducer, easy to operate and mainteance.

4. The corrugated forming system is in combination with water cooling and air cooling to sensure high production speed

continuously.Advanced programmable lubricating system minimizes the moulds wear so as to increase the life of service and ensure work smmothly with high precision to ensure the products quality stability.

5. Mould adopts specialy alumium alloy material and high precision die casting forming mould method,it has the advanages of high precision,high stremgth,good wearability and better heat dissipation performance.

6. Wave structure launched a comprehensive new optimization design to reach the best combination of high-rigidity and low weight.

Plastic PVC|PE|PP|HDPE Double Wall Corrugated Cable Duct|Tube Extrusion Equipment|Dwc Extuder Machine Machinery Air Ventilation Pipe Extruder Equipment

Diameters: 40-110MM, 75-200MM(or customized);Flexible HDPE double-walled corrugated pipe application:

HDPE / PP double wall corrugated pipe is widely used as cable protection pipe, fresh air ventilation pipe,cable ducting and etc.. The company absorbs foreign advanced technology, independent research and development of the HDPE double wall corrugated pipe production line, with a number of patented technologies. Our new high-speed PE double-wall corrugated pipe production line, the use of new high-performance single-screw extruder, forming machine using horizontal structure, shuttle drive, sealed water-cooled, auto recoiling, high degree of automation, stable operation, large output.

Mould block use innovate design that inner can be aluminum to cooling temperature fast. The bank of mould block is 45# steel which is anitcorrosion during running.

Die Head and Calibration sleeve

Both outer layer and inner layer are extruded inside die head. Each material flow channel inside die head is placed evenly. Each channel is after heat treatment and mirrorpolishing to ensure material flow smoothly. Also die head provides compressed air between both layer.Calibration sleeve is used to cool inner layer to form smooth and flat pipe inside. Pressure water flows inside calibration sleeve to have good cooling effect. Vacuum is created on calibration sleeve surface when producing big diameter pipe, ensure inner pipe roundness.

1.This production line can be used to produce corrugated pipes of PE,PP,PVC,EVA continuously,as well as PA corrugated pipes.

2.Plastic single wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility, etc

3.They are widely used in fields of auto wire, electric thread passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc

Plastic EVA Single Wall Corrugated Pipe Tube Hose Extruder Making Machine for Vacuum Dust Cleaner Features:

Fully PLC controlled mahine

High and stable extrusion capacity

Corrugator mould one mould two size

Good water cooling or air cooling system

Progress of Plastic EVA Single Wall Corrugated Pipe Tube Hose Extruder Making Machine for Vacuum Dust Cleaner :

Raw material + master batches→mixing→vacuum feeding →material dryness →single screw extruder→extrusion mould→corrugation forming machine→meter measurer→double winder→finished product inspecting &packing

Product Description

High Speed Flexible Shrinkable Pa Pe Pp Pvc Single Wall Corrugated Tube Hose Pipe Manufacturing Machine Equipment Manufacturer

Shrinkable Single Wall Corrugated Pipe Machine, Corrugated Tube Hose Pipe Manufacturing Machine, Single Wall Corrugated Pipe Equipment

Machinery introduction: New Design extruder our extruders adopt famous MOTOR,TAIWAN DELTA INVERTOR, omron temperature controller , The two electrical boxes are merged into one, which is easy to install and operate The main machine can adjust the base, the precision of

the mould is higher after fine adjustment Beautiful appearance, small occupation.

Pipe Application:

Our HDPE corrugated pipe can be Perforated or non-perforated, perforated pipe is used in land drainage applications ,By its name perforated pipe has perforations along the pipe. This allows water to enter the pipe through these perforated holes. They are thus suitable for sub soil drainage systems. Ideally suited to applications such as Field Drain or French Drains.

DOUBLE WALL CORRUGATED PIPE MAKING MACHINE

PE/HDPE double wall corrugated pipe making production machine adopts extruding and forming process, it has the features of reliable quality and high efficiency. Compared with other plastic pipe wall structure, double wall corrugated pipe has excellent wall structure design, its low weight reach the lower production cost and improve the market competitiveness. The pipe is widely used in various field instead of concrete pipe and iron pipes,because it has excellent features such as:easy connected and accessories installed, and quality reliable.

Product use:

Perforated corrugated Pipe with geotextile for the reliable drainage of Golf course; Sports grounds ,farmland , tunnel ,Water conservancy ,roads , Highway ,refuse landfill, highways,streets,airports,track systems ,Landscaping projectsand irrigation systems,in all cases with higher demands for drainage pipes.

underground perforated corrugated drainage pipe factory

Plastic Sylphon Bellows Extrusion Machine

The sylphon bellows extrusion mahcine not only can be used to manufacture flexible pipe for generator, electrical wire but other corrugated pipe, such as double wall corrugated pipe, cable threading pipe, washing machine inlet hose, construction conduit pipe etc.

The raw materials of corrugated hdpe pipes machines are PE, PVC, PP and series of the thermoplastic.

Plastic Extruder Plastic Double Wall Corrugated Pipe Water Gas HDPE PP Pipe Making Machinery Extruding Extrusion Machine

anti-corrosion,good ring stiffness and flexibility. Our company has developed PE double wall corrugated pipe extrusion line formore than 20 years. We have the whole series of double wall corrugated pipe machine: horizontal type, verticaltype and shuttle type. Our machine can process wide range of material, including HDPE, PP, PVC, etc.

Forming Machine

The sylphon bellows extrusion mahcine not only can be used to manufacture flexible pipe for generator, electrical wire but other corrugated pipe, such as double wall corrugated pipe, cable threading pipe, washing machine inlet hose, construction conduit pipe etc.

The raw materials of corrugated hdpe pipes machines are PE, PVC, PP and series of the thermoplastic.

The consistants of corrugated pipe extrusion machine are extruder, corrugated pipe shaping machine, corrugated pipe chain mold.

The price of flexible pipe machine is a competitive factory price, the electrical wire machine is supplied by factory directly.

PVC corrugated tube making machine

drainage corrugated tube making machine

corrugated tube making machine for air contioner

Plastic PE PP PVC double wall corrugated tube produce equipment

Double wall corrugated pipe is mature product which has the advantage of low weight, low cost, anti-corrosion,good ring stiffness and flexibility. Our company has developed PE double wall corrugated pipe extrusion line formore than ten years. We have the whole series of double wall corrugated pipe machine: horizontal type, verticaltype and shuttle type. Our machine can process wide range of material, including HDPE, PP, PVC, etc.

HDPE double wall corrugated pipe making machine

dwc pipe manufacturing machine

corrugated pipe is mainly used for water drainage system. It is a fully computer controlled line. It features high and stable output capacity, and highly automatic operation. For HDPE, you can choose high efficient single screw extruder. For PVC, you can choose conical twin-screw extruder or parallel twin- screw extruder. Forming system consists mould and corrugator.

Mould blocks can be easily changed and they have air or water cooling system. The belling process is on line. High precision cutting can be guaranteed by cutting machine. The production line can also be equipped with SIEMENS PLC system.

| Type Pipe | Diameter(mm) | HDPE Output(kg/h) | MAX Speed(m/min) |

| CS-160 | 50-160 | 300-400 | 5 |

| CS-500 | 200-500 | 600-700 | 3 |

| CS-800 | 200-800 | 1000-1100 | 3 |

| CS-1200 | 600-1200 | 1000-1200 | 1 |

Customized PP/PE Corrugated Hose Making Machines Flexible Spiral Single Wall Corrugated Pipe Extrusion Machines Manufacturer

high speed PP PE single wall double wall corrugated pipe manufacture extruder making machine DWC corrugated pipe making machine

Plastic corrugated flexible pipe making machineplastic single wall corrugated pipe extrusion line can produce PP/PE/PVC/EVA/PA corrugated pipe.Mould Chain adopts gear transmission,base plate adopts water cooling,mould adopts air cooling.

Corrugated pipe produced by our machine has the features of high production speed,even corrugated shape,straight pipe seam,and smooth surface. By equipped with vacuum pump and vacuum type mould,it can produce different use corrugated pipe with joint(wash basin drain pipe,air conditioner pipe,hookah pipe etc.)

Extrusion line for the production of single-wall and double wall corrugated tubes and pipes made of PE, PP, PVC, PA, EVA, PVDF, TPE etc.

plastic single wall corrugated pipe machine

Main Technical Parameter---Single Wall Corrugated Pipe Make Machine:

| Extruder Model | SJ45 | SJ65 |

| Screw diameter (mm) | 45 | 65 |

| Ration of L/D | 28-33:1 | 28-33:1 |

| Pipe diameter range | 9-32 | 32-110 |

| Pairs of modules | 40 | 72 |

| Line speed (m/min) | 3-15 | 3-15 |

| Module cooling way | Air-cooled | Air-cooled |

| Pipe cooling way | Air-cooled | Air-cooled |

| Total install powder (kw) | 50 | 70 |

Building industry: electrical conduit & sanitary hose duct/flexible pipe for siphon, PP-PE-PVC-PA

Automotive industry: Fuel line pipe & wiring harness tubing, PP-PA6-PA11-PA12-PA612

Medical industry: breathing tubes, LLDPE,EVA

The range includes: Water cooling corrugator, Blow forming system corrugator, Vacuum forming system corrugator, Sequential mode corrugator, Variable Chain Length corrugator.

features of plastic corrugation pipe production machine

1. PP/PE/PA/PVC/EVA production line can be used to produce single-wall corrugated pipes.

2. Plastic single-wall corrugated pipes have features of high temperature resistance, resistant to corrosion and abrasion, high intensity, good flexibility, etc. They are widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc.

HDPE Perforated Corrugated Pipe extruder production line

Flexible Perforated Corrugated Drain Pipe is used in land drainage(underground) applications ,By its name perforated pipe has perforations along the pipe. This allows water to enter the pipe through these perforated holes. They are thus suitable for sub soil drainage systems. Ideally suited to applications such as Field Drain or French Drains.

Name: | HDPE double-wall corrugated drain pipe/Large pe pipe |

Outside diameter(mm): | 200-800mm |

Colors: | blue, black or other colors on request |

Use: | water supply,irrigation,house building,industry,drain |

| working tempreature | -60°c~60°c |

Standard | ISO14001,ISO9001/BV/ GB/T19472.1-2004 |

Material | PE80 or PE100 |

Lifetime | Over 50 years |

Pressure | SN4 and SN8 |

Connection | Stock butt-fusion, electro-fusion, flanged |

- Plastic single-wall corrugated pipe production line developed by our company adopts gears to run moulds and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall. These corrugated pipes are especially used as wires of the up-market cars.

-

Product Description

Product descriptionPerforated pipe plastic Flexible Perforated Corrugated Drain Pipe With Sock is used in land drainage(underground) applications ,By its name perforated pipe has perforations along the pipe. This allows water to enter the pipe through these perforated holes. They are thus suitable for sub soil drainage systems. Ideally suited to applications such as Field Drain or French Drains.

HDPE/UPVC underground drain pipe

HDPE/UPVC underground drain pipe is the main raw material of polyethylene resin and high density polyethylene (HDPE) has excellent chemical stability, aging resistance and environmental stress cracking. The HDPE double-wall bellows, which is produced by its raw materials, belong to the flexible pipe, which is extruded to fit the new type of pipe for the outdoor drainage and municipal discharge. HDPE/UPVC double wall corrugated pipe has the advantages of light weight, small displacement resistance, high compressive strength, corrosion resistance and convenient construction. Underground drainage pipe is an ideal material to replace cast iron pipe and cement pipe.

thread-passing pipes, wires protective pipe, tubes of air conditioner and washing machine etc.

1: Lightweight, quick construction, and lower cost.

2: The buried service life is more than 50 years.

3: Polyethylene is a hydrocarbon polymer, its molecules are non-polar and resistant to acid and alkali corrosion.

4: The raw materials are green environmental protection materials, non-toxic, non-corrosive, non-scaling, and can be recycled and reused.

6: The applicable temperature range is wide, the pipeline will not break in an environment of -60ºC, and the maximum temperature of the conveying medium is 60ºC.

7: The cost of the comprehensive project is basically equivalent to that of concrete, and the operating cost is low.

8: No foundation is needed when the soil is good.

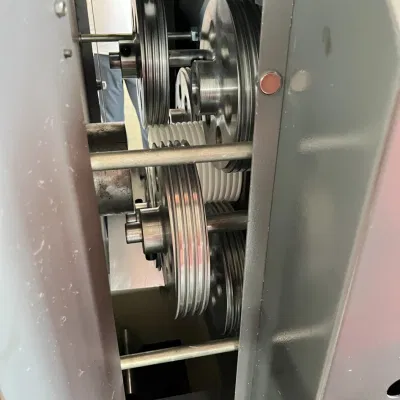

Gear material is 20CrMoTi. Nitriding and teeth grinding treatment, hard tooth surface reducer.

Equip with force lubrication system and external cooling water circulation system.

Connect with motor directly, so better deceleration effect. Long service span, low noise and low heating.

corrugated Pipe Forming Machine SJ-50 Single Screw Extruder Plastic Machinery Corrugated Pipe Extruder Manufacturer

3. Delivery.

4. We will provide after-sales service:

(1) Field installation and commissioning;

(2) Field training your workers;

(4) Free Spare Parts ;

(5) Video/Online technical support.

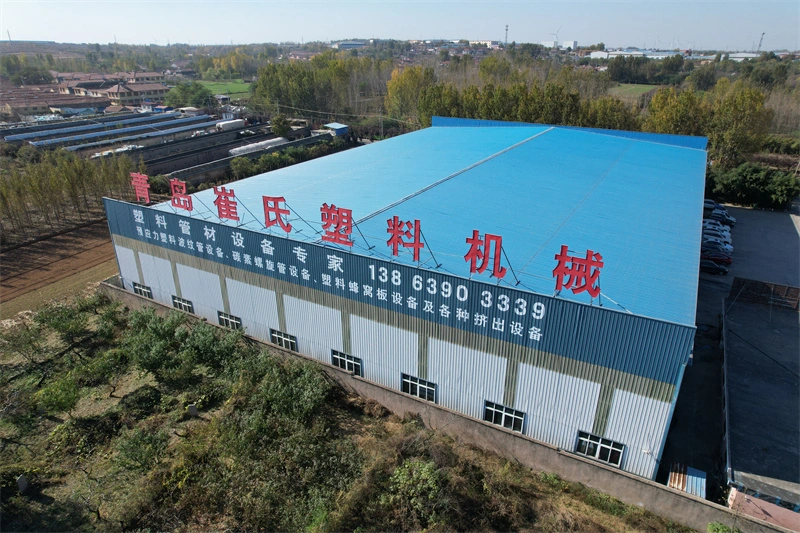

Company Introduction

Qingdao cuishi Plastic machinery Co.,Ltd is a high-tech enterprise which is specialized in research, manufacture and marketing plastic extrusion lines, plastic production line. Our plastic extrusion lines based on Plastic Extruders: Single Screw Extruder, Conical Twin Screw Extruder and Parallel Twin Screw Extruder. Our plastic making machine can make many kinds of plastic productions like: PVC pipe, CPVC pipe, PE/HDPE/PE-RT pipe, PP-R pipe,plastic foamed profile, WPC profile and panel, wood plastic composite and so on. Plastic Extruder is widely used in Plastic industry. It is the main part of Plastic Pipe Extrusion Line, Plastic Profile Extrusion Line, Plastic Recycling Line and Plastic Granulating Line. Our plastic extruder use good quality screw in plastic machinery. Our plastic machine have long-life.

Product Description

Plastic PPR HDPE Pipe Machine/Plastic Corrugated Pipe Tube Machine/Plastic Pipe Production Line/Plastic Pipe Manufacturing Plant/PVC Pipe Making Machine

Qingdao cuishi Plastic machinery Co.,Ltd is the proffesional manufacturer for plastic extrusion line located in Qingdao city China. The company specially good at different type of plastic pipe making machine.

Our Service

Installation service

When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our factory,and see the machine running.

Customized service

We can design the machines according your requirements(materil,power,filling type,the kinds of the bottles,and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

2.When you finish the Preparation conditions,our fast and professional aftersales service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

3. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

4.We provide one year warranty

5.Well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

7 .12 Months guarantee and life-long technical support.

8.Your business relationship with us will be confidential to any third party.

9. Good after-sale service offered, please get back to us if you got any questions.

Quality Control

We have the single quality department,that make sure the material of the raw materials is good,and ensure the machine running smoothly.