Basic Info.

Model NO.

AD800

Normal Service Life

50 Years

Advantages

High Stiffness, Light Weight, Stable, Long Service

Transport Package

20′/40′ Container

Origin

China

HS Code

3917390000

Production Capacity

30000 Meters/Month

Product Description

High-Quality and Economical Corrugated Pipe

Introduction:

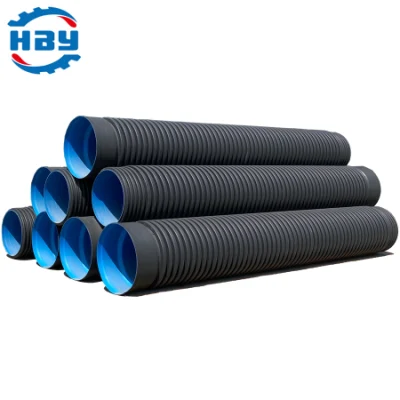

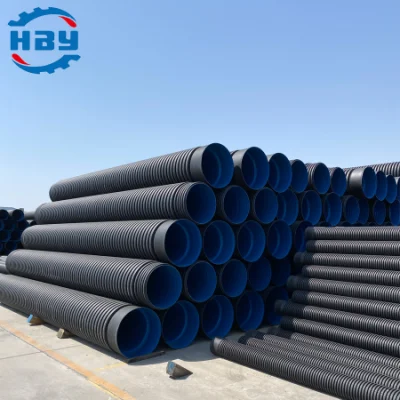

HDPE double wall corrugated pipes is a new type of pipe with annular outer wall and smooth inner wall. Its main raw material is high-density polyethylene. This products are suitable for gravity and low pressure drainage system of urban or industrial sewage, sanitary sewage, rainwater drainage, etc.

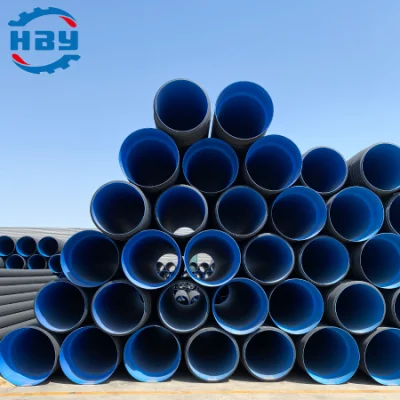

HDPE steel belt reinforced spiral corrugated pipes are the third generation of steel - plastic composite structure pipe prepared by two - step molding process. This product combines the rigidity of steel strips with the corrosion resistance of polyethylene for lighter weight and higher strength. The products can be widely used in urban sewage pipes, bridge and culvert road sewage and drainage pipes, agricultural irrigation pipes, water source water intake pipes and so on.

Specifications:

HDPE Double Wall Corrugated Pipes:

HDPE Steel Belt Reinforced Spiral Corrugated Pipes:

Note: Length can be customized according to actual demand.

Physical Properties:

HDPE Double Wall Corrugated Pipes:

HDPE Steel Belt Reinforced Spiral Corrugated Pipes:

Standard Features:

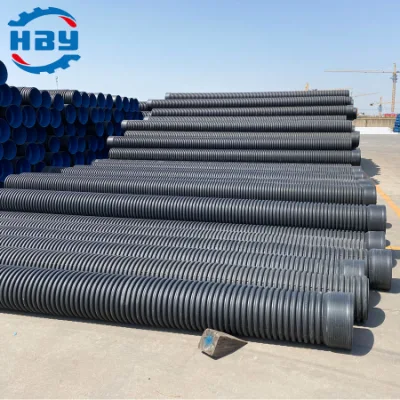

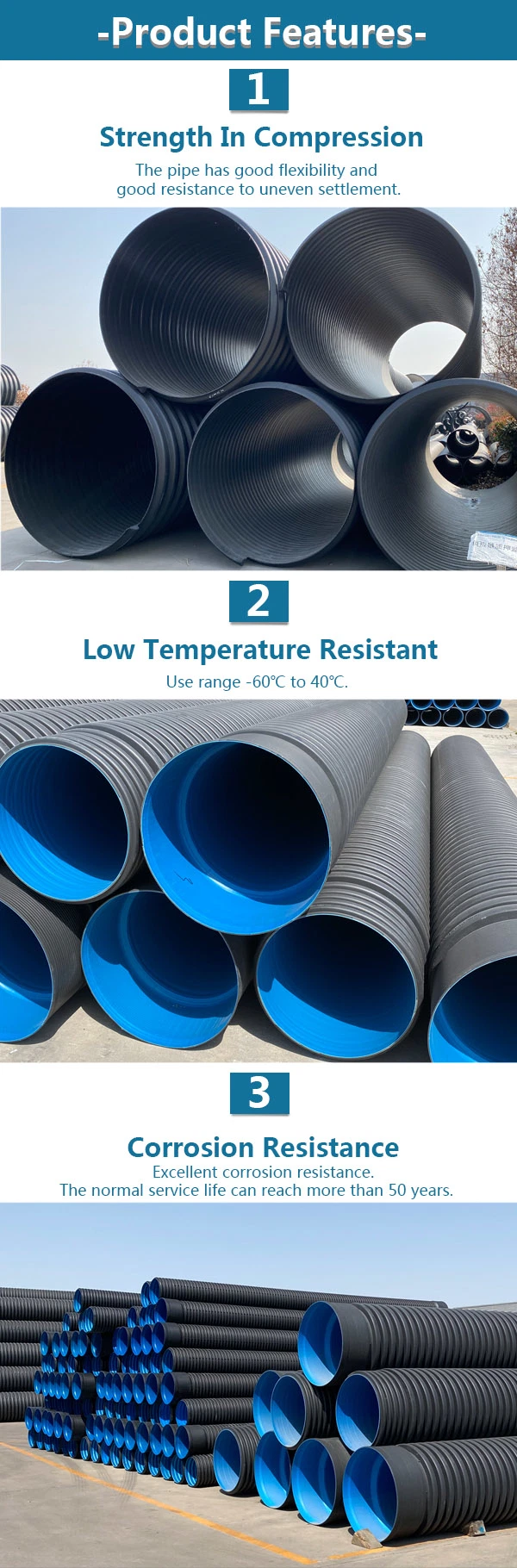

The normal service life can reach more than 50 years.

Excellent corrosion resistance.

Wear resistance is more than 4 times that of steel pipe.

Low temperature resistance: range of -60ºC to 40ºC.

The pipe has good flexibility and good resistance to uneven settlement.

The connection mode is diverse and the connection is firm.

Application Scenarios:

1. Public works: buried underground for drainage pipes and sewage pipes.

2. Road engineering: used for railway, highway infiltration ditch or drainage pipe.

3. Industry: widely used in sewage pipelines in industrial areas.

4. Construction engineering: used for building rain pipe, underground drainage pipe, drainage pipe, exhaust pipe, etc.

5. Landfill sewage collection pipe.

6. Large port and wharf engineering: drainage pipe and drainage pipe for large airport, port and wharf engineering.

7. Sports ground: drainage ditch and drainage pipe used for golf course, football field and other sports ground.

8. Water conservancy project: Used as head pipe, irrigation pipe.

9. Mine: used for ventilation, blasting, drainage pipe, pulp pipe, etc.

10. Communication engineering: used for railway, highway communication pipe, communication cable pipe and optical cable protection pipe.

11. Water storage system: Used to intercept slow water flow in the water storage system.

12. Agricultural engineering: farmland, garden, tea garden, forest belt as irrigation pipeline.

Introduction:

HDPE double wall corrugated pipes is a new type of pipe with annular outer wall and smooth inner wall. Its main raw material is high-density polyethylene. This products are suitable for gravity and low pressure drainage system of urban or industrial sewage, sanitary sewage, rainwater drainage, etc.

HDPE steel belt reinforced spiral corrugated pipes are the third generation of steel - plastic composite structure pipe prepared by two - step molding process. This product combines the rigidity of steel strips with the corrosion resistance of polyethylene for lighter weight and higher strength. The products can be widely used in urban sewage pipes, bridge and culvert road sewage and drainage pipes, agricultural irrigation pipes, water source water intake pipes and so on.

Specifications:

HDPE Double Wall Corrugated Pipes:

| Diameter DN/ID(mm) | Minimum Mean Inside Diameter(mm) | Minimum Laminated Wall Thickness(mm) | Minimum Inner Wall Thickness(mm) | Suggestion Connection Length(mm) |

| 200 | 195 | 1.5 | 1.1 | 54 |

| 300 | 294 | 2.0 | 1.7 | 65 |

| 400 | 392 | 2.5 | 2.3 | 74 |

| 500 | 490 | 3.0 | 3.0 | 85 |

| 600 | 588 | 3.5 | 3.5 | 96 |

| 800 | 785 | 4.5 | 4.5 | 118 |

| 1000 | 985 | 5.0 | 5.0 | 140 |

HDPE Steel Belt Reinforced Spiral Corrugated Pipes:

| IDX | Diameter DN/ID(mm) | Minimum Mean Inside Diameter(mm) | Minimum Inner Wall Thickness(mm) | Minimum Laminated Wall Thickness(mm) | The Biggest Pitch(mm) | Minimum Strip Thickness(mm) |

| 1 | 300 | 294 | 2.5 | 4.0 | 75 | 0.4 |

| 2 | 400 | 392 | 3.0 | 4.5 | 85 | 0.4 |

| 3 | 500 | 490 | 3.5 | 5.0 | 100 | 0.5 |

| 4 | 600 | 588 | 4.0 | 6.0 | 110 | 0.5 |

| 5 | 700 | 685 | 4.0 | 6.0 | 115 | 0.5 |

| 6 | 800 | 785 | 4.5 | 7.5 | 120 | 0.7 |

| 7 | 1000 | 985 | 5.0 | 8.0 | 150 | 0.7 |

| 8 | 1200 | 1185 | 5.0 | 8.0 | 180 | 0.7 |

| 9 | 2000 | 1985 | 6.0 | 9.0 | 235 | 1.0 |

Physical Properties:

HDPE Double Wall Corrugated Pipes:

| Item | Unit | Index | ||

| TIR | ≤10% | |||

| Flexible Ring | The pattern is smooth and the wall is not broken | |||

| Ring-stiffness | SN2 | KN/m² | ||

| SN4 | KN/m² | |||

| SN8 | KN/m² | |||

| Oven Test | No bubbles, no delamination, no cracking | |||

| Creep Ratio | ≤4 | |||

HDPE Steel Belt Reinforced Spiral Corrugated Pipes:

| IDX | Item | Unit | Index | ||

| 1 | Ring-stiffness | SN8 | KN/m² | ≥8 | |

| SN10 | KN/m² | ≥10 | |||

| SN12.5 | KN/m² | ≥12.5 | |||

| 2 | TIR | ≤10% | |||

| 3 | Peel Strength(23ºC±2ºC) | N/cm | ≥100 | ||

| 4 | Flexible Ring | The tube wall is not broken, and the two walls are not detached. | |||

| 5 | Oven Test | No delamination, no cracking. | |||

| 6 | Tensile Strength Of Laminated Wall Of Pipe | 300≤DN/ID≤500 | N | ≥600 | |

| 600≤DN/ID≤800 | N | ≥840 | |||

| 900≤DN/ID≤1200 | N | ≥1020 | |||

| 7 | Creep Ratio | ≤2 | |||

Standard Features:

The normal service life can reach more than 50 years.

Excellent corrosion resistance.

Wear resistance is more than 4 times that of steel pipe.

Low temperature resistance: range of -60ºC to 40ºC.

The pipe has good flexibility and good resistance to uneven settlement.

The connection mode is diverse and the connection is firm.

Application Scenarios:

1. Public works: buried underground for drainage pipes and sewage pipes.

2. Road engineering: used for railway, highway infiltration ditch or drainage pipe.

3. Industry: widely used in sewage pipelines in industrial areas.

4. Construction engineering: used for building rain pipe, underground drainage pipe, drainage pipe, exhaust pipe, etc.

5. Landfill sewage collection pipe.

6. Large port and wharf engineering: drainage pipe and drainage pipe for large airport, port and wharf engineering.

7. Sports ground: drainage ditch and drainage pipe used for golf course, football field and other sports ground.

8. Water conservancy project: Used as head pipe, irrigation pipe.

9. Mine: used for ventilation, blasting, drainage pipe, pulp pipe, etc.

10. Communication engineering: used for railway, highway communication pipe, communication cable pipe and optical cable protection pipe.

11. Water storage system: Used to intercept slow water flow in the water storage system.

12. Agricultural engineering: farmland, garden, tea garden, forest belt as irrigation pipeline.