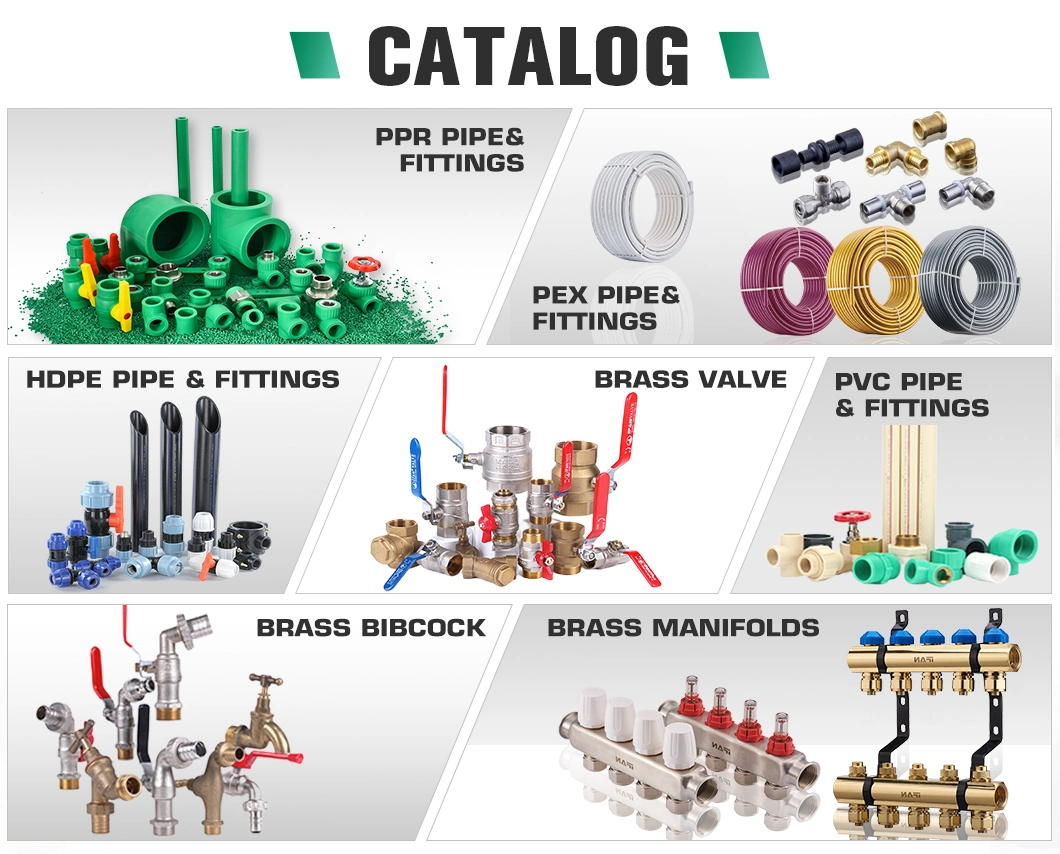

- Overview

- Product Description

- Our Advantages

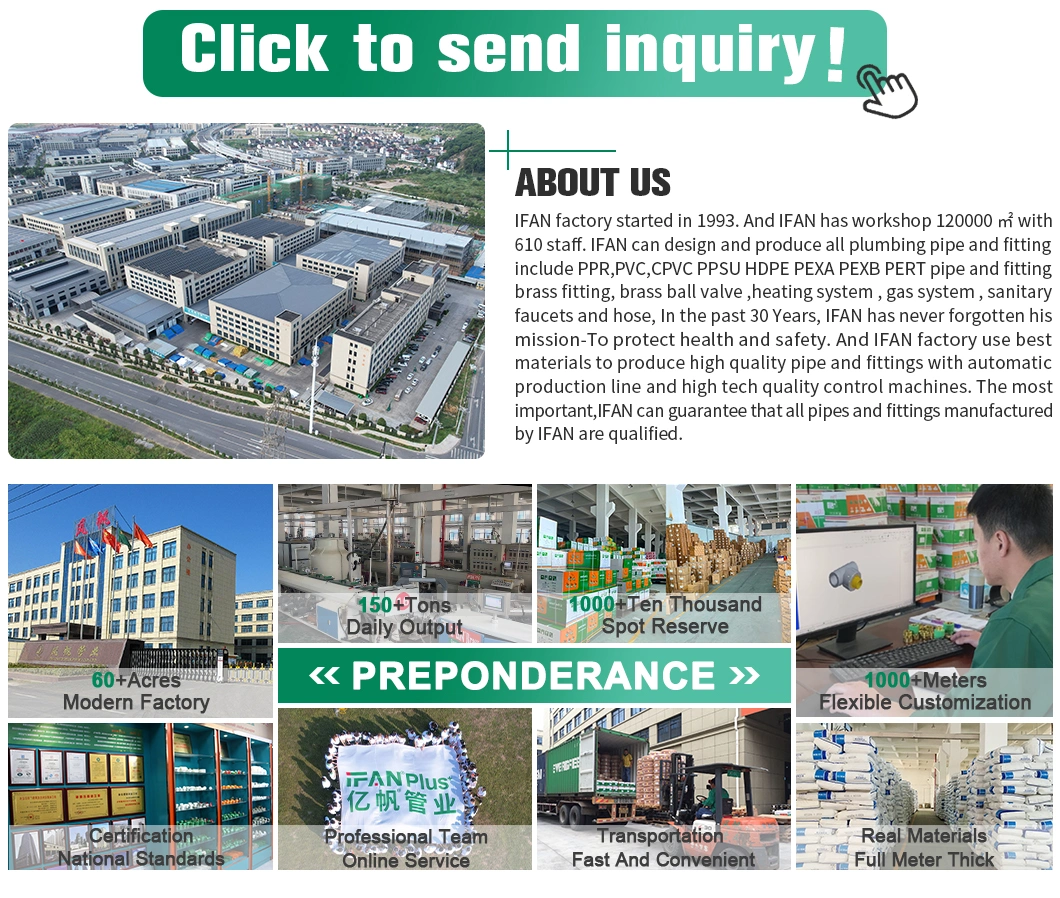

- Company Profile

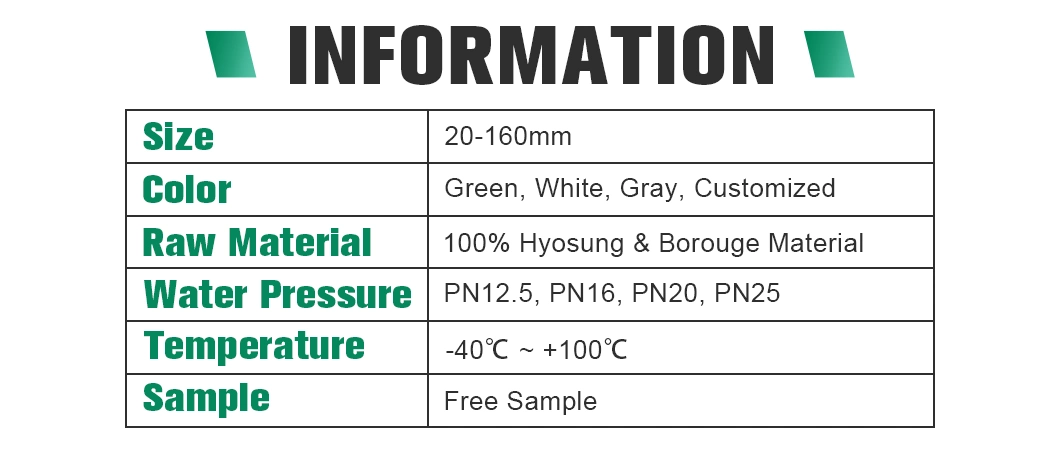

Basic Info.

Model NO.

PPR Pipe

Kind

Thermosetting Plastics Pipe

Water Absorption

Other

Contraction Percentage

Other

Tensile Strength

Other

Connection

Welding

Sample

Free Sample

Customized Service

OEM & ODM

Application

Water Supply

Working Pressure

Pn12.5-Pn25

Transport Package

Ifan Woven Bag

Specification

20-160mm

Trademark

IFAN

Origin

China

HS Code

3917220000

Production Capacity

1000PCS/Day

Packaging & Delivery

Package Size

20.00cm * 20.00cm * 15.00cm

Package Gross Weight

0.200kg

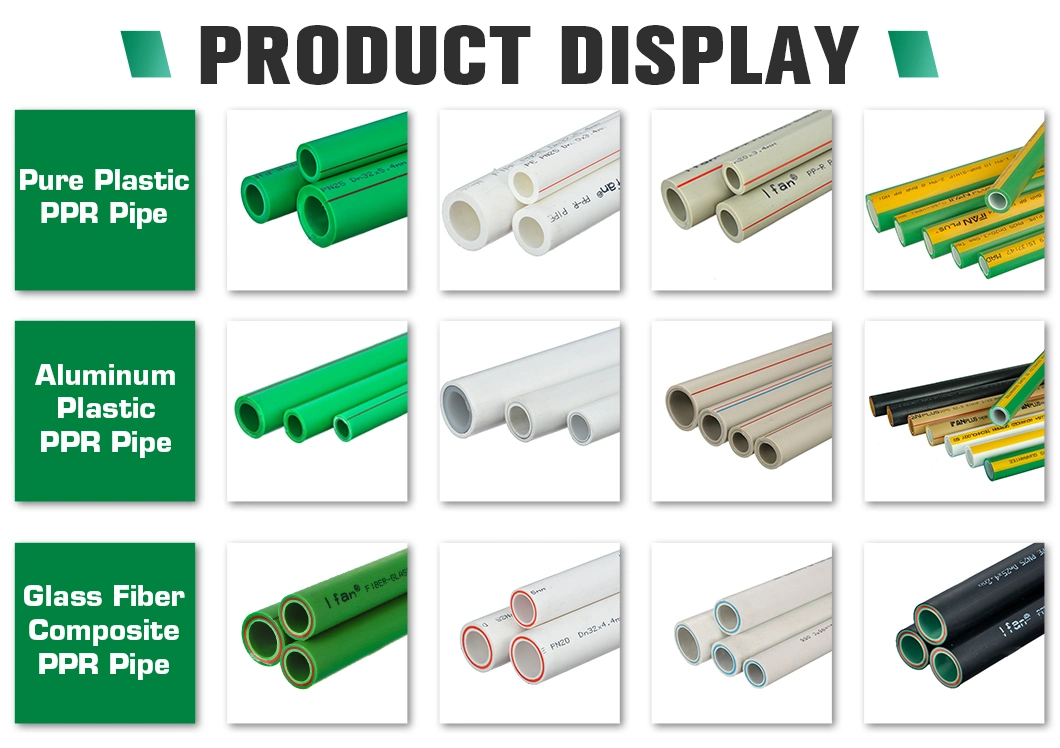

Product Description

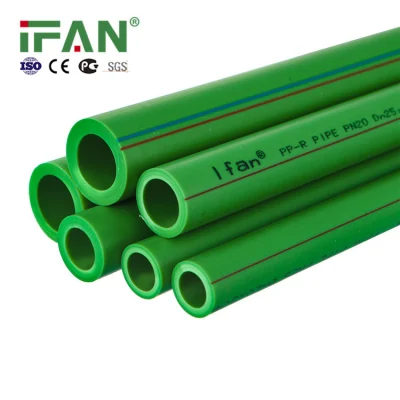

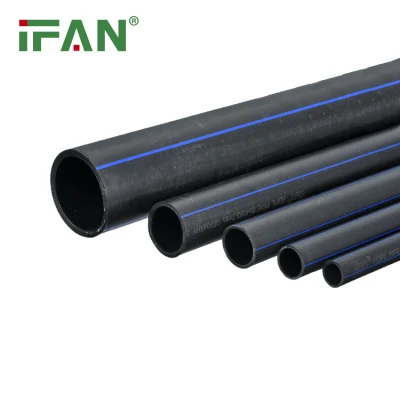

Ifan Piping Systems High Pressure Plastic HDPE PPH PVC PEX PPR Pipe For Water Gas

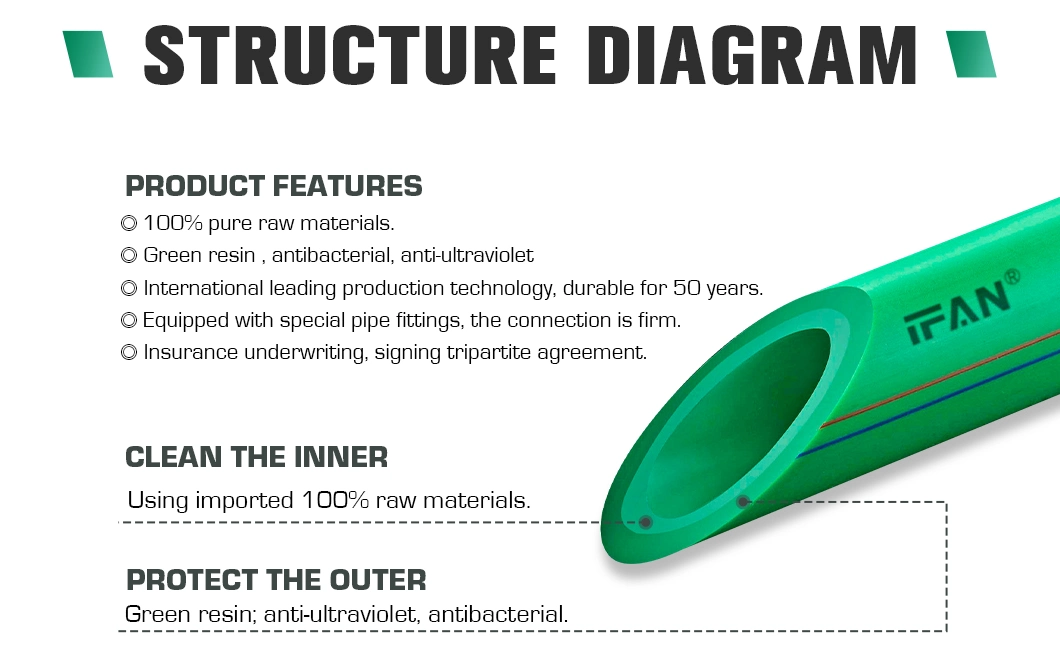

PPR (Polypropylene Random) Pipe is a type of plastic piping system that is commonly used in plumbing and water supply applications. PPR pipe is made from a high-quality thermoplastic polymer called polypropylene random copolymer, which has been specially designed for use in pipes and fittings. In this article, we will discuss the material, advantages, and other important aspects of PPR pipe.

Material:

The primary material used in the manufacturing of PPR pipes is polypropylene random copolymer. This material is a type of thermoplastic that is known for its excellent physical and chemical properties. Polypropylene random copolymer has a high melting point, which means that it can withstand high temperatures without deforming or melting. It is also resistant to chemicals, which makes it an ideal material for use in applications that involve the transport of chemicals or other corrosive substances.

Advantages:

There are several advantages to using PPR pipes over other types of piping systems. Here are some of the most significant advantages:

1. Longevity: PPR pipes are designed to last for a long time. They have a life expectancy of over 50 years, which is much longer than other types of plastic pipes.

2. Durability: PPR pipes are very durable and can withstand high pressures and temperatures. They are also resistant to impact and abrasion, which makes them ideal for use in high-traffic areas.

3. Easy to Install: PPR pipes are lightweight and easy to install, which means that they can be installed quickly and with minimal effort. They are also available in a range of sizes and lengths, which makes them suitable for a wide range of applications.

4. Cost-Effective: PPR pipes are generally more cost-effective than other types of piping systems. They are cheaper to produce, and they require less maintenance over time, which can lead to significant cost savings over the long term.

5. Hygienic: PPR pipes are made from a material that is resistant to bacteria and other microorganisms. This means that they are more hygienic than other types of piping systems, and they are less likely to harbor harmful bacteria.

6. Environmentally Friendly: PPR pipes are made from a material that is recyclable, which means that they can be reused or repurposed at the end of their useful life. This makes them a more environmentally friendly option than other types of piping systems.