Basic Info.

Model NO.

16-32

Base Pipe of Plastic Composite Pipe

Overlapped and Buttwelded

Internal Coating Materials of Plastic Composite Pipe

Polyethylene Coating Steel Pipe

Plastic Composite Pipe Coating Form

Inner and Outside Coating

Plastic Composite Pipe Model

PE-Al-PE or Pex-Al-Pex or PE-Al-Pex

Aluminium Plastic Compound Pipe Use

Water Distribution Pipe in Building

Aluminium Plastic Compound Pipe Material

High Density Polyethylene Aluminum Composite Pipe

Szie

16-63mm

Transport Package

CTN Boxes, Knitting Bags, Kraft Papers, Pallets

Specification

Aenor,Skz,SGS,Watermark,Acs,Wras,Snas,Jaswic,CE

Trademark

MSP/MINGSHI/OEM

Origin

China

HS Code

39173900

Production Capacity

7million Meters/ Month

Product Description

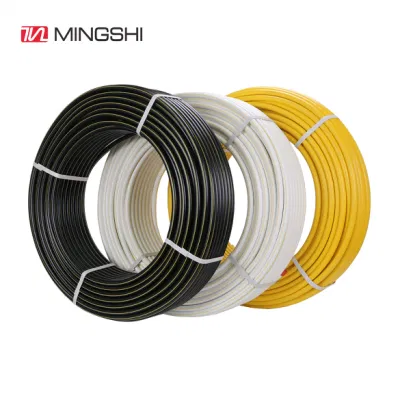

| Multilayer PEX-AL-PEX/ PERT-AL-PERT Pipe | |

| Warranty | More than 10 years |

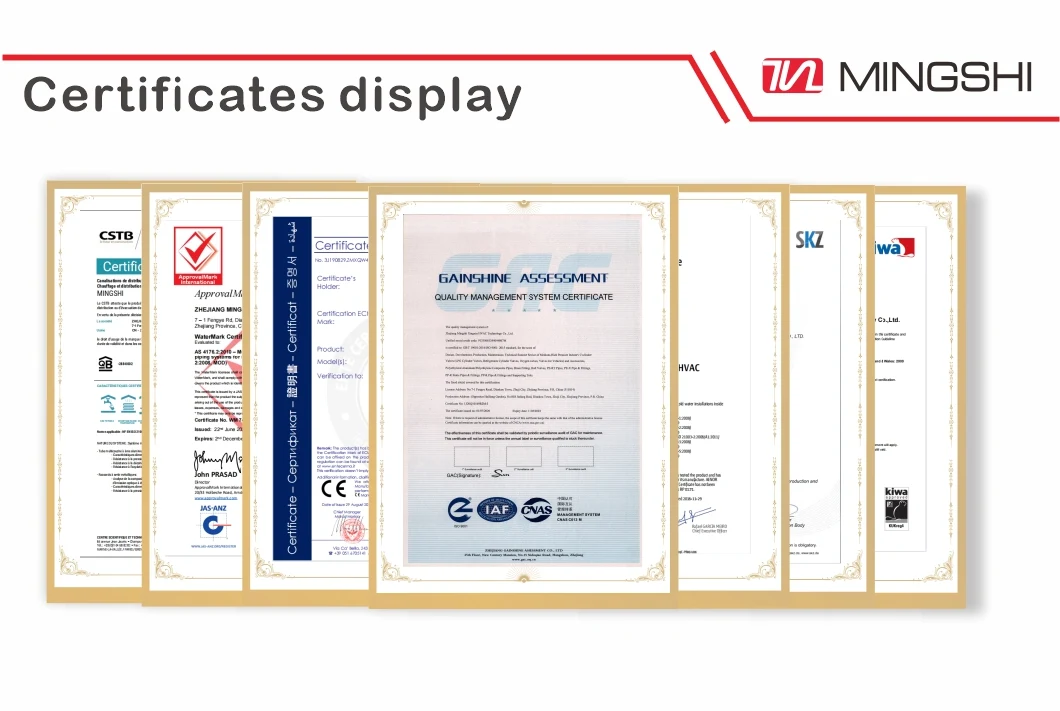

| Certification | AENOR, WRAS, CSTB, ACS, WATERMARK, SKZ |

| Application | Water/ Gas/ Underfloor heating (UFH) |

| Customized support | OEM, ODM |

| Place of Origin | China, Zhejiang |

| Brand Name | OEM/MINGSHI/MSP |

| Model Number | S-1 |

| Standard | ISO 21003/ other |

| Welding types | Buttwelding/ Overlapped |

| OD (mm) | 15/ 16/ 18/ 20/ 22/ 25/ 26/ 28/ 32/ 40/50/63 |

| Colors | White/ Black/ Red/ Blue/ Yellow/ Orange |

| Working pressure | Max. 10 bars |

| Working temperature | Max. 95ºC |

| Crosslinking degree | ≥65% |

1. For water(cold & hot)/gas pipe system, Composed of 5 layers:

-External Plastic/external Glue/Aluminum/internal Glue/internal Plastic

2. Certificates we have: CSTB, AENOR, WRAS, SKZ, SNAS, PHZ, SGS, WATERMAKR, STANDARDSMARK

3. Material: CONSTAB PEX

4. QC: Including spot inspection on production lines, all the tests required by each standard done in our lab rooms

5. Overlapped/buttwelding

-Spec. (mm)

16*2.0

18*2.0

20*2.0

20*2.25

25*2.5

26*3.0

32*3.0

40*4.0

50*4.5

63*6.0

6. Lead time: 15-30days

7. Main makets: Europe, Asia, Australia

8. Applications:

-Cool & Hot Water Pipe System

-Housing Gas Pipe System

-Under floor heating System

-Solar Energy & Air-conditioning Matching Pipe System

-Medical, Foodstuff & Chemical Industry Pipe System

9. Characters & Advantages:

-Wide range working temperature(-10C~95C), Hi-pressure resistance

-30% more flow than metal pipe

-50 year working life

-Non-corrosive, scale-free

-Hygiene, no oxygen permeability, no growth of Microorganism

-Non-inflammable, non-static

-Easy bending but never spring back

-Light in weight, easy to carry and store

-Few pipe fitting applying leading to little leakage

-Economical price.

| International Standards | ||

| 1 | EN ISO 21003 | Multilayer piping systems for hot and cold water installations inside buildings |

| 2 | AS 4176.2 & 3 | Multilayer piping systems for hot and cold water plumbing applications- PIPES & FITTINGS |

| 3 | ISO17484-2:2009 | Multilayer Plastics piping systems for indoor gas installations |

| International Certificates | ||

| 1 | AENOR | refers to EN ISO 21003,UNE-EN ISO 53007 |

| 2 | CSTB | refers to EN ISO 21003 |

| 3 | ACS | refers to XP P41-250 |

| 4 | Watermark | refers to AS 4176.2 & 3 |

| 5 | WRAS | refers to Regulators' Specification |

| 6 | ISO 9001:2015 | Quality management system |

| Size&Tolerance | ||||||||||

| Nominal size(D x e) | 14×2.0 | 16×2.0 | 18×2.0 | 20×2.0 | 25×2.5 | 32×3.0 | 40x4.0 | 50x4.5 | 63x6.0 | |

| Outside diameter (mm) | 14 | 16 | 18 | 20 | 25 | 32 | 40 | 50 | 63 | |

| Tolerance of Outer diameter (mm) | Min | 14 | 16 | 18 | 20 | 25 | 32 | 40 | 50 | 60.6 |

| Max | 14.3 | 16.3 | 18.3 | 20.3 | 25.3 | 32.3 | 40.4 | 50.5 | 63 | |

| Inside diameter(mm) | 10 | 12 | 14 | 16 | 20 | 26 | 32 | 41 | 51 | |

| Tolerance of Inner diameter (mm) | Min | 9.9 | 11.9 | 13.9 | 15.9 | 19.9 | 25.9 | 30.9 | 39.4 | 49.3 |

| Max | 10.2 | 12.2 | 14.2 | 16.2 | 20.2 | 26.2 | 31.9 | 40.8 | 50.8 | |

| Pipe thickness (mm) | 2 | 2 | 2 | 2 | 2.5 | 3 | 4 | 4.5 | 6 | |

| Tolerance of pipe thickness (mm) | Min | 2 | 2 | 2 | 2 | 2.4 | 2.9 | 4 | 4.5 | 6 |

| Max | 2.25 | 2.25 | 2.25 | 2.25 | 2.7 | 3.2 | 4.6 | 5.2 | 6.8 | |