Basic Info.

Material

PEX-Al-PEX

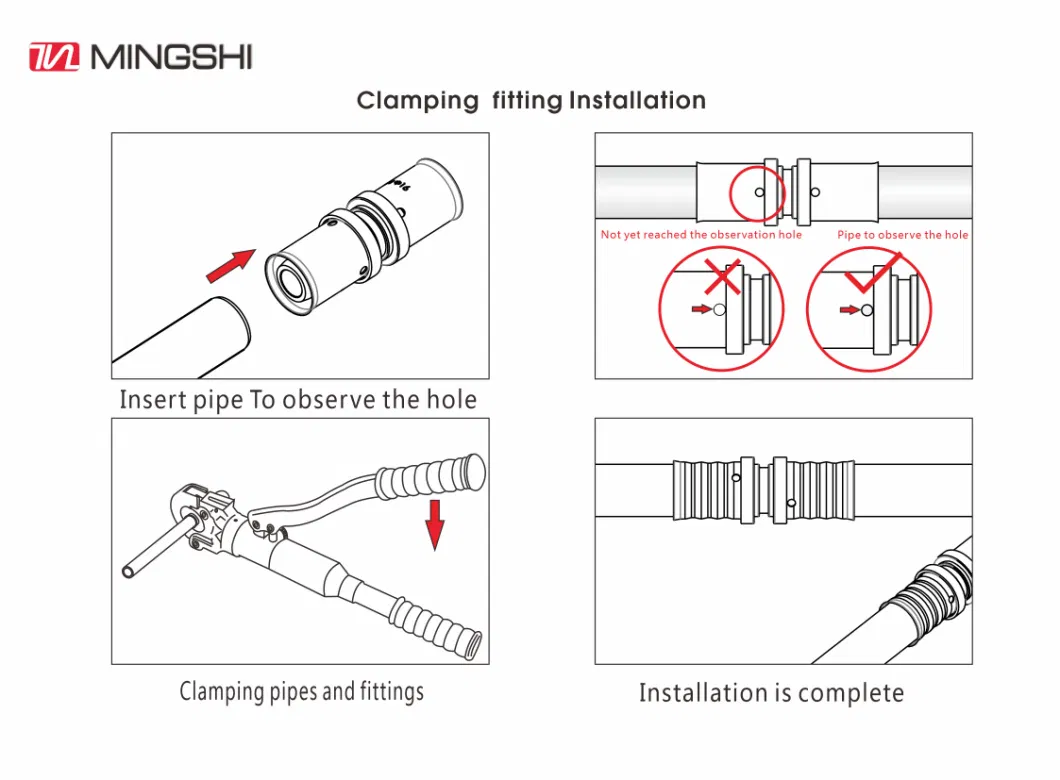

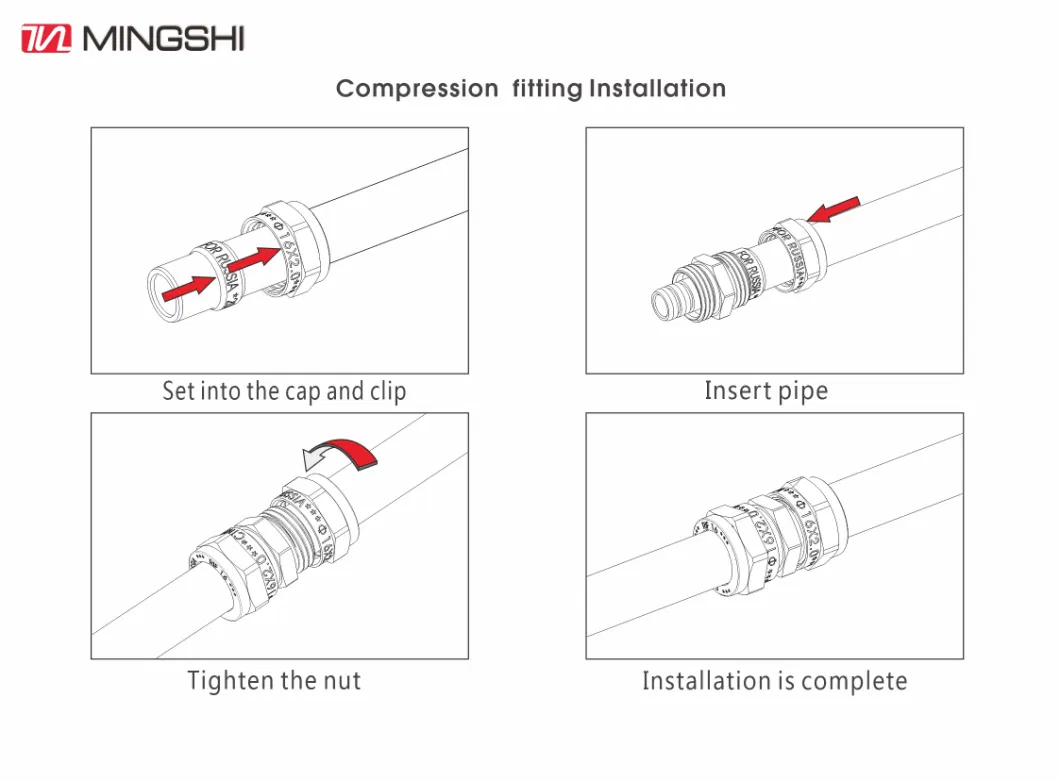

Installation and Connection

Clamping Type Installation

Technology of Plastic Composite Pipe

Internal and External Coating

Base Pipe of Plastic Composite Pipe

Lase Welding /Overlapped Welding

Plastic Composite Pipe Coating Form

Inner and Outside Coating

Plastic Composite Pipe Model

16-63mm

Aluminium Plastic Compound Pipe Material

Crosslinked Polyethylene Aluminum Composite Pipe

Size

12, 16, 18, 20, 25, 32, 40, 50, 63mm

Transport Package

CTN Boxes, Knitting Bags, Kraft Papers, Pallets

Specification

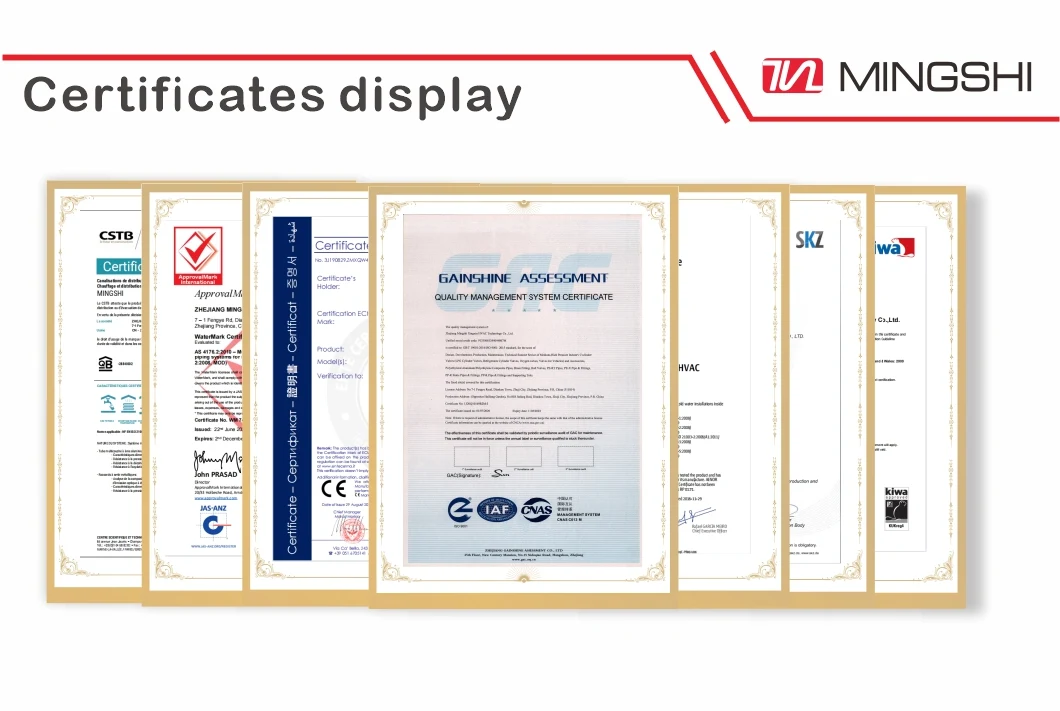

Aenor, Skz, Snas, Phz, SGS, Watermakr, Jaswic

Trademark

MSP/MINGSHI/OEM

Origin

China

HS Code

3917300000

Production Capacity

7million Meters/ Month

Packaging & Delivery

Package Size

35.00cm * 20.00cm * 15.00cm

Package Gross Weight

5.000kg

Product Description

| Essential details | |||||

| Place of Origin: | Zhejiang,China | Material: | Pex,PE | ||

| Specification: | 16-63MM | Length: | 25/50/100/200/300/500 or OEM | ||

| Thickness: | 2.0, 2.5, 3.0, 4.0, 4.5, 6.0 | Standard: | AENOR,SKZ,WRAS,WATERMARK | ||

| Processing Service: | Cutting | Product name: | Pex-Al-Pe pipe | ||

| Application: | Gas system,Water system, Under floor heating. | Type: | Plastic Building Material | ||

| Raw Material: | Pex, Aluminum | Colors: | White,Red,Blue,Orange,Red or OEM | ||

| Logo: | Support custom logo | Features: | Corrosion Resistant,fire resistant,high pressure | ||

| MOQ: | 10000m | Shape: | Round | ||

| Advantage: | Flexible,easy to install | ||||

| Supply Ability | |||||

| Supply Ability: | 3000000 Meters per month | ||||

| Packing&Delivery | |||||

| Packing Details: | With craft paper, then plastic film outside/Plastic bag | ||||

| Port: | Ningbo or Shanghai | ||||

| International Standards | ||

| 1 | EN ISO 21003 | Multilayer piping systems for hot and cold water installations inside buildings |

| 2 | AS 4176.2 & 3 | Multilayer piping systems for hot and cold water plumbing applications- PIPES & FITTINGS |

| 3 | ISO17484-2:2009 | Multilayer Plastics piping systems for indoor gas installations |

| International Certificates | ||

| 1 | AENOR | refers to EN ISO 21003,UNE-EN ISO 53007 |

| 2 | QB | refers to EN ISO 21003 |

| 3 | ACS | refers to XP P41-250 |

| 4 | Watermark | refers to AS 4176.2 & 3 |

| 5 | WRAS | refers to Regulators' Specification |

| 6 | ISO 9001:2015 | Quality management system |

| Size&Tolerance | ||||||||||

| Nominal size(D x e) | 14×2.0 | 16×2.0 | 18×2.0 | 20×2.0 | 25×2.5 | 32×3.0 | 40x4.0 | 50x4.5 | 63x6.0 | |

| Outside diameter (mm) | 14 | 16 | 18 | 20 | 25 | 32 | 40 | 50 | 63 | |

| Tolerance of Outer diameter (mm) | Min | 14 | 16 | 18 | 20 | 25 | 32 | 40 | 50 | 60.6 |

| Max | 14.3 | 16.3 | 18.3 | 20.3 | 25.3 | 32.3 | 40.4 | 50.5 | 63 | |

| Inside diameter(mm) | 10 | 12 | 14 | 16 | 20 | 26 | 32 | 41 | 51 | |

| Tolerance of Inner diameter (mm) | Min | 9.9 | 11.9 | 13.9 | 15.9 | 19.9 | 25.9 | 30.9 | 39.4 | 49.3 |

| Max | 10.2 | 12.2 | 14.2 | 16.2 | 20.2 | 26.2 | 31.9 | 40.8 | 50.8 | |

| Pipe thickness (mm) | 2 | 2 | 2 | 2 | 2.5 | 3 | 4 | 4.5 | 6 | |

| Tolerance of pipe thickness (mm) | Min | 2 | 2 | 2 | 2 | 2.4 | 2.9 | 4 | 4.5 | 6 |

| Max | 2.25 | 2.25 | 2.25 | 2.25 | 2.7 | 3.2 | 4.6 | 5.2 | 6.8 | |