Basic Info.

Customized

Customized

Condition

New

After-sales Service

Provide

Total Power

110kw

Output

150-180kg/H

Splitting Machine

Automatic

Scrfp Edge

Self-Motion Adjustable

Transport Package

Nude Packing

Specification

22*2.5*3

Trademark

weier

Origin

Shandong

HS Code

84772090

Production Capacity

20set Per Month

Product Description

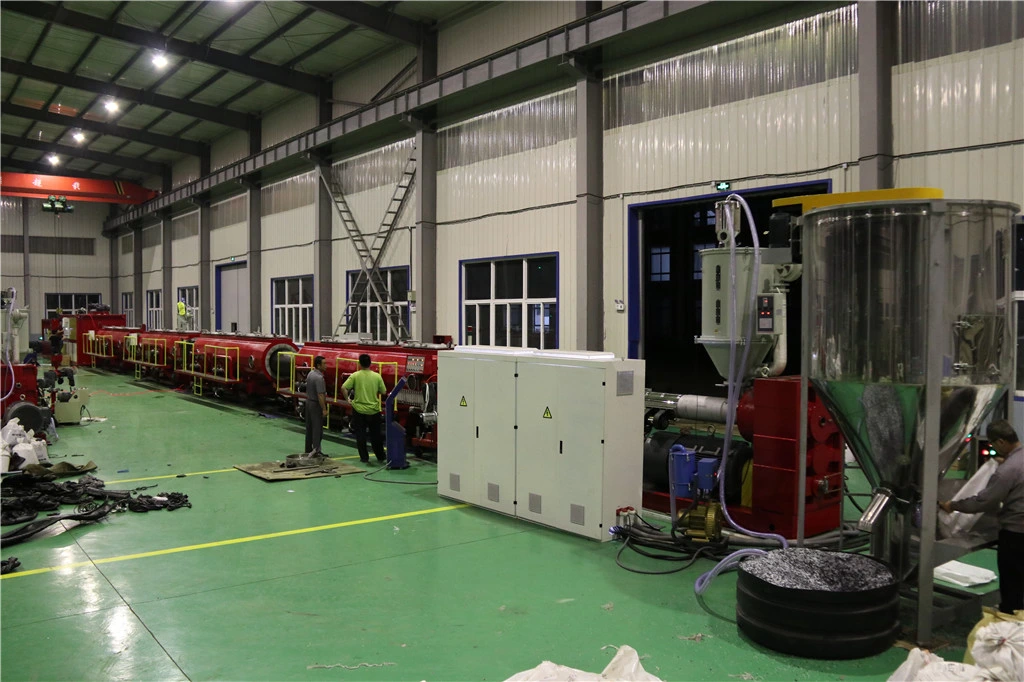

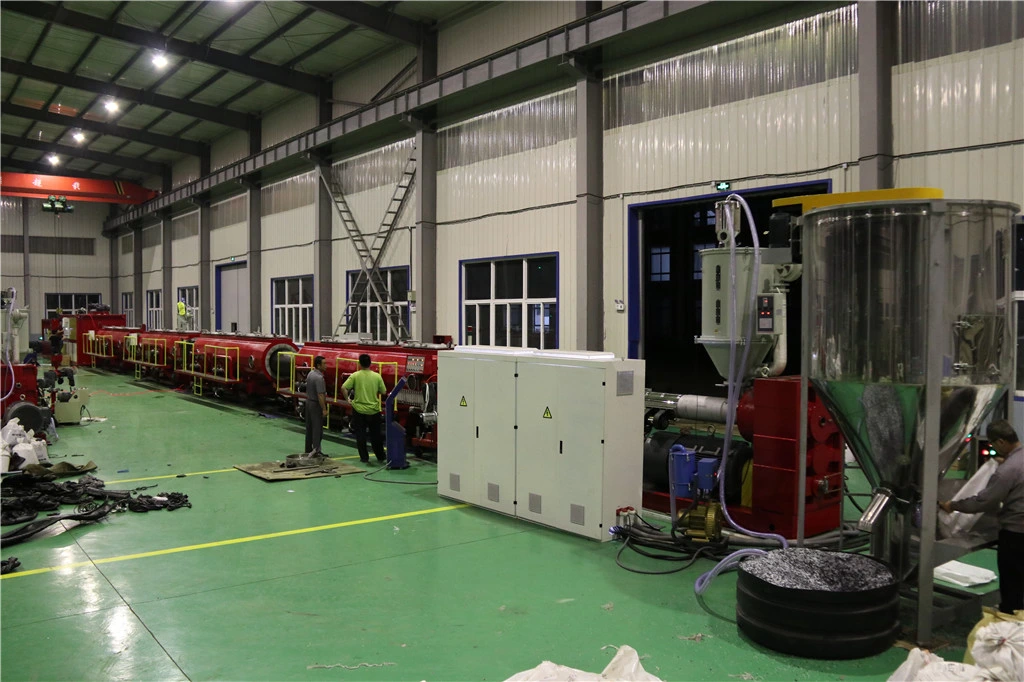

315-630mm HDPE Pipe Extrusion Line

---Produce Application---

PE pipe production line is primarily used in the manufacturing of PE pipes with diameters ranging from 16mm to 1200mm. The various thickness of the pipes produced can make them suitable for applications range from urban water supply to gas transportation. This line also excels in the production of anti-flammable and anti-static electricity pipes using a two or three layer spiral mould for use in mining industries. Pipes produced feature even wall-thickness and perfect roundness. Through switching or adding certain part of machine unit, this line can also be customized to extrude pipes of various other kinds.

PE pipe production line is primarily used in the manufacturing of PE pipes with diameters ranging from 16mm to 1200mm. The various thickness of the pipes produced can make them suitable for applications range from urban water supply to gas transportation. This line also excels in the production of anti-flammable and anti-static electricity pipes using a two or three layer spiral mould for use in mining industries. Pipes produced feature even wall-thickness and perfect roundness. Through switching or adding certain part of machine unit, this line can also be customized to extrude pipes of various other kinds.

---Features at a glance---

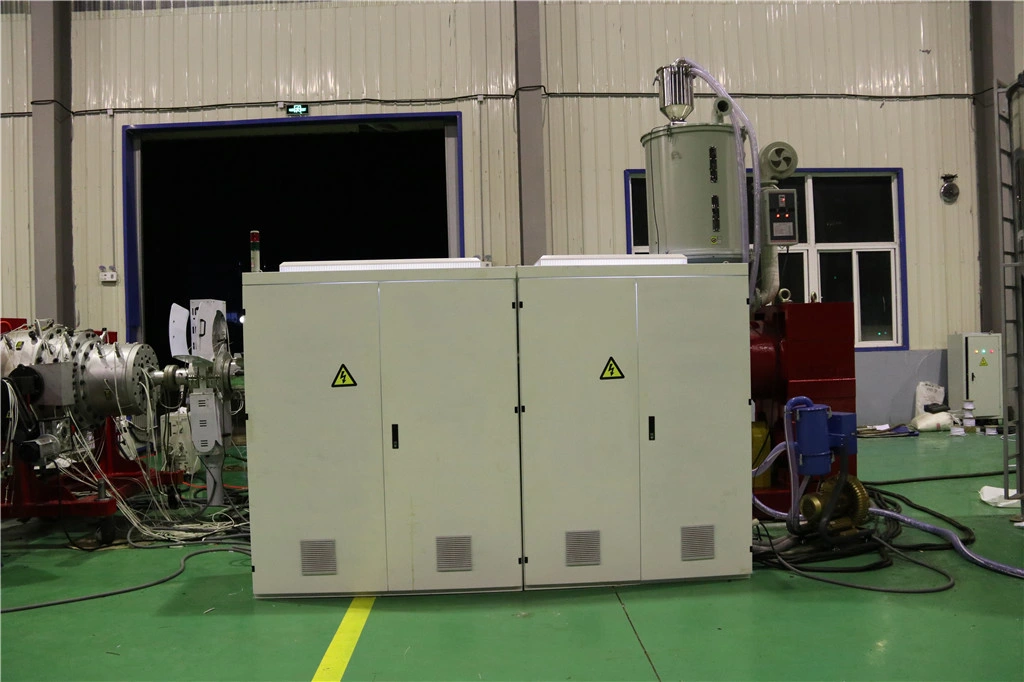

The extrusion line is used to produce 315-630mm pipes. The line is equipped SJ120/33 extruder with main motor 250kw, output up to 800kg/h. And the equipment is equipped with a screen changer, which is used to filter impurities when use recycling materials. PLC control system can store more than 200 pieces of temperature, speed data,automatic synchronously adjusts the speed of extruder,co-extruder, dragger,winding machine!

---Product Details---

SJ120/33 Single screw extrider

Using the high efficient single screws SJ120 with L/D 33:1, main motor 250kw,maximum production 800kg/h ,specially designed for PP,PE granule material to ensure uniformed plasticization, highextrusion. Stable temperature controlling system can guarantee high quality pipe extrusion.

Using the high efficient single screws SJ120 with L/D 33:1, main motor 250kw,maximum production 800kg/h ,specially designed for PP,PE granule material to ensure uniformed plasticization, highextrusion. Stable temperature controlling system can guarantee high quality pipe extrusion.

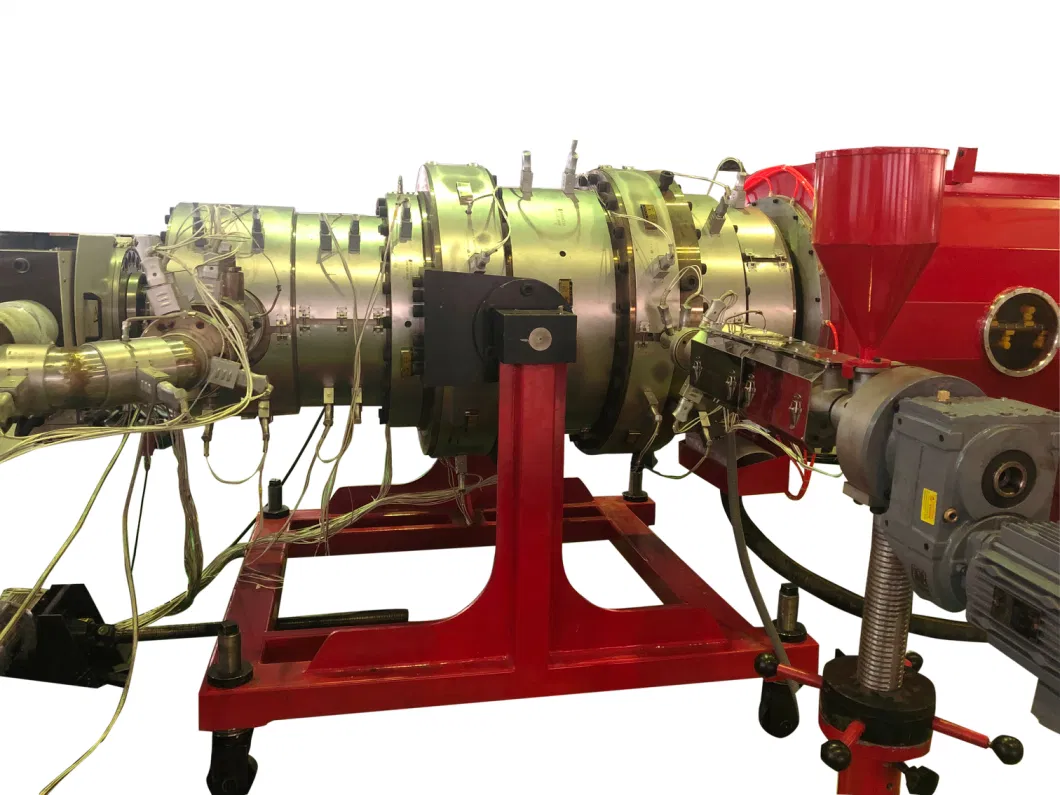

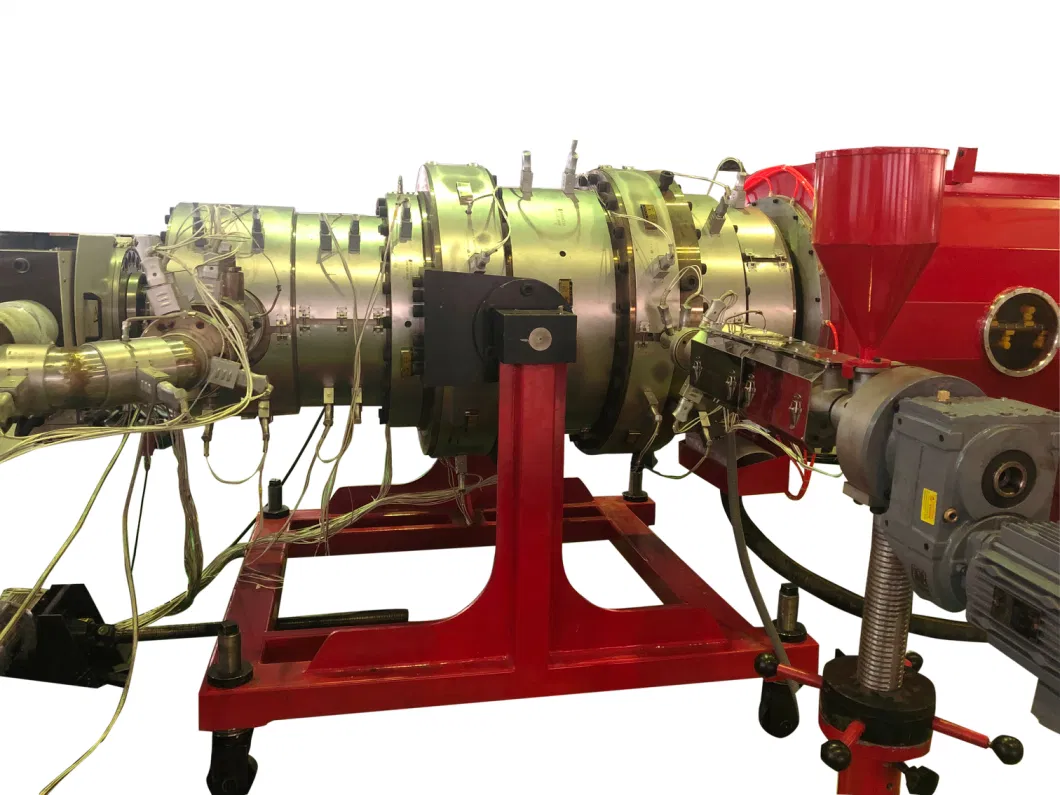

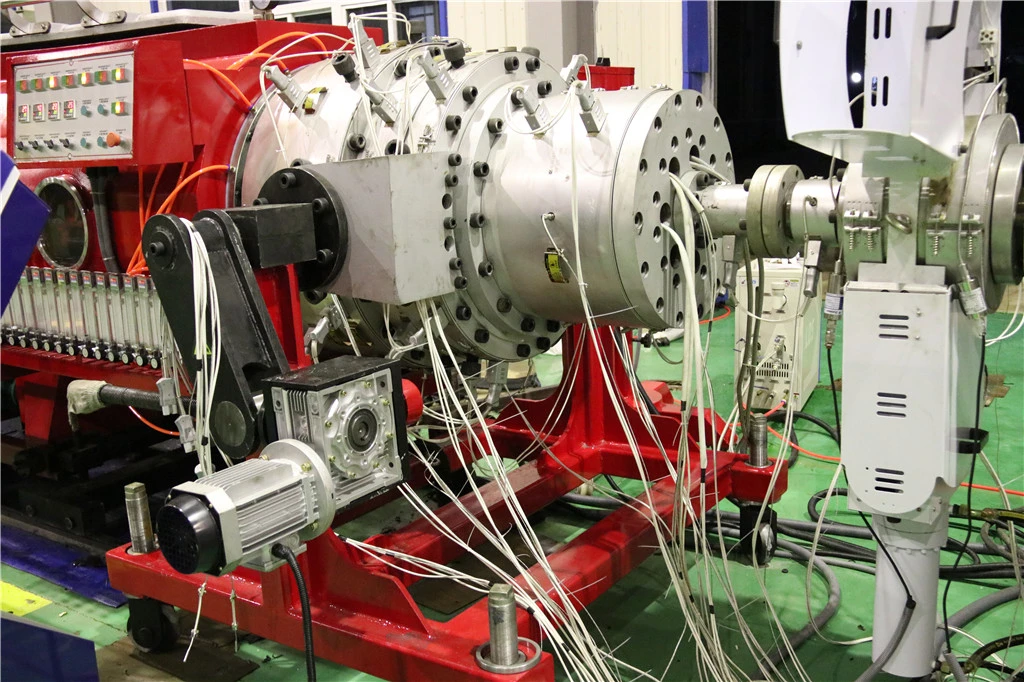

315-630mm Pipe extrusion Mould

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get highquality pipes. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make

the pipes fast calibrated and cooled.

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get highquality pipes. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make

the pipes fast calibrated and cooled.

Vacuum cooling tank

Rapid vacuum calibrating system allows the hot extruded pipes to be cooled in a very short time and obtain the final pipe diameter. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the pipe sizing and cooling performance as well as the production speed.

Spraying cooling tank

Take away the waste heat from the pipe,Intelligent control of water supply and drainage.

Six-jaw haul off machine

Adopts caterpillar type, which includes two-jaw types, three-jaw types, four-jaw types, six-jaw types, eight -jaw tepes,ten-jaw types etc, suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed. According to customer demand, can be equipped with winch for the first boot.

Adopts caterpillar type, which includes two-jaw types, three-jaw types, four-jaw types, six-jaw types, eight -jaw tepes,ten-jaw types etc, suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed. According to customer demand, can be equipped with winch for the first boot.

Cutting machine

Precision machine cutter is able to make flat, straight cuts into pipes at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

Precision machine cutter is able to make flat, straight cuts into pipes at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

---Company Profile---

FAQ

1.Why choose us?

We are the professional manufacture focus on HDPE Pipe Production Line/HDPE Pipe Extrusion Machine/HDPE Pipe Line/HDPE Pipe Machine/PPR Pipe Extrusion Line and etc...

2.What's the advantage do we have?

We adopt high efficient extruder with deep groove and water recycle inside, high capacity,high efficient,energy saving;We have the updated product that keep innovate tehcnology according to the market requirement