- Overview

- Product Description

- Product Parameters

- Application

- Certifications

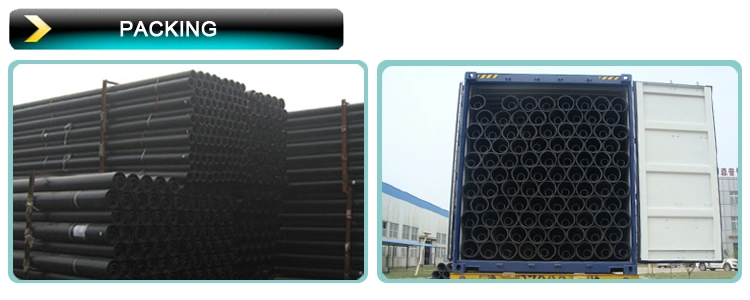

- Packaging & Shipping

- Company Profile

Basic Info.

Model NO.

20-1200mm

SDR

SDR33, SDR26, SDR21, SDR17, SDR13.6, SDR11, SDR9

Pression

Pn4, Pn6, Pn8, Pn10, Pn12.5, Pn16, Pn20

Material Suppier

Sinopec, Basell, Sabic, Borouge

Pipe Density

0.95-0.96kg/M3

Nwt

0.007kg-196kg

Pipe Life Span

50 Years

International Standard

ISO4427/4437, DIN8074/8075

Other

Cutomized

Transport Package

Bulk or Plastic Bags

Specification

Dn20mm~~Dn1200mm

Trademark

SP/SR

Origin

China(Mianland)

HS Code

3917210000

Production Capacity

10000 Meters/Day

Product Description

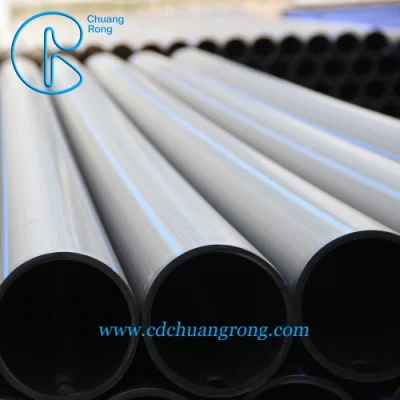

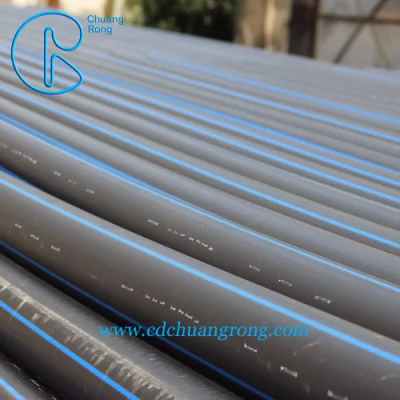

Perfessional HDPE Water Pipe SDR17

1.Raw material:PE100 or PE80

2.Color:black with blue stripe or as required

3.Specification:please see the following table

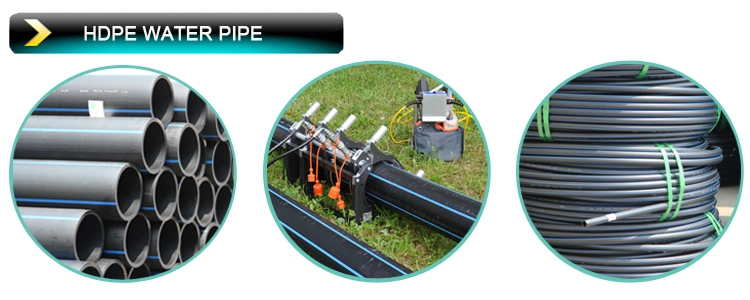

4:Connecting way:socket fusion, butt fusion or electrofusion

5.Advantage:ODM.OEM

6.Pressure:PN16 (SDR11),PN12.5 (SDR13.6),

PN10 (SDR17.6),PN8 (SDR21),PN6(SDR26)

7.Product feature:light weight,high strength,

low resistance,corrosion resistance,easy installation,long lifespan,low cost

| PE100 | 0.4MPa | 0.5MPa | 0.6MPa | 0.8MPa | 1.0MPa | 1.25MPa | 1.6MPa | 2.0MPa | 2.5MPa |

| Outside Diameter (mm) | PN4 | PN5 | PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | PN25 |

| SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | SDR7.4 | |

| Wall Thickness (en) | |||||||||

| 20 | - | - | - | - | - | - | 2.0 | 2.3 | 3.0 |

| 25 | - | - | - | - | - | 2.0 | 2.3 | 3 | 3.5 |

| 32 | - | - | - | - | 2.0 | 2.4 | 3.0 | 3.6 | 4.4 |

| 40 | - | - | - | 2.0 | 2.4 | 3.0 | 3.7 | 4.5 | 5.5 |

| 50 | - | - | 2.0 | 2.4 | 3.0 | 3.7 | 4.6 | 5.6 | 6.9 |

| 63 | - | - | 2.5 | 3.0 | 3.8 | 4.7 | 5.8 | 7.1 | 8.6 |

| 75 | - | - | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | 10.3 |

| 90 | - | - | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | 12.3 |

| 110 | - | - | 4.2 | 5.3 | 6.6 | 8.1 | 10.0 | 12.3 | 15.1 |

| 125 | - | - | 4.8 | 6.0 | 7.4 | 9.2 | 11.4 | 14 | 17.1 |

| 140 | - | - | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | 19.2 |

| 160 | - | - | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | 21.9 |

| 180 | - | - | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | 24.6 |

| 200 | - | - | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | 27.4 |

| 225 | - | - | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 | 25.2 | 30.8 |

| 250 | - | - | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | 34.2 |

| 280 | - | - | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | 38.3 |

| 315 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 | 43.1 |

| 355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 | 48.5 |

| 400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 | 54.7 |

| 450 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 | 61.5 |

| 500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 | - |

| 560 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 | - |

| 630 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 | - |

| 710 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 | - |

| 800 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 | - |

| 900 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | - | - |

| 1000 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | - | - |

| 1200 | 29.4 | 36.7 | 45.9 | 57.2 | 67.9 | 88.2 | - | - | - |

| 1400 | 34.3 | 42.9 | 53.5 | 66.7 | 82.4 | 102.9 | - | - | - |

| 1600 | 39.2 | 49 | 61.2 | 76.2 | 94.1 | 117.6 | - | - | - |

Note:Italics emboldening specification executive enterprise standards

CHUANGRONG DN20-DN1200 HDPE PIPE Properties :

1.Specific Gravity, g/cm3, 20(C): 0.941-0.965

2.Longitudinal Reversion, % (110(C)): <=3

3.Oxidation Induction Time, min (200(C)): >=20

4.Extension Rate at Break. %: >=350

5.Hydraulic Pressure Test:

1)20(C), Hoop Stress is 12.4Mpa, 100h: No Failure.

2)80(C), Hoop Stress is 5.5Mpa, 165h: No Failure.

3)80(C), Hoop Stress is 5.0Mpa, 1000h: No Failure.

Applications:

1.Municipal water supply, gas supply and agriculture etc.

2.Commercial & Residential water supply

3.Industrial liquids transportation

4.Sewage treatment

5. Food and chemical industry

7. Replacement of cement pipes and steel pipes

8. Argillaceous silt, mud transportation

9. Garden green pipe networks

Certification:

We can supply ISO9001-2008, BV ,SGS, CE etc certification.

Inspection:

All kinds of products are regularly conducted pressure-tight blasting test,longitudinal shrinkage rate test, quick stress crack resistance test, tensile test and melt index test, so as to ensure the quality of products totally reach the relevant standards from raw materials to finished products.

Packing: loaded into container

CHUANGRONG is a leading professional supplier of plastic pipe system products since 2005.We have exported our products more than 80 countries and area.

Our products:1.Plastic pipe 2.HDPE fittings 3.PPR fittings 4.PP compression fittings 5.pipe welding machine and tools 6.pipe repair clamp Our aim is to provide customer with the best solutions of plastic pipe connection.

Thank you for your looking through.