Basic Info.

Model NO.

HDPE Composite Pipe

Contraction Percentage

<0.4%

Tensile Strength

30~40MPa

Production Capaction

300, 000t/Year

Certificate

ISO9001, CE, Wras

Production Standard

GB/CE/ISO....

Length

6m, 9m, 12m or Customized

Transport Package

Customized

Specification

DN50-DN710

Trademark

LANGBOONE

Origin

China

HS Code

39172100

Production Capacity

300, 000t/Year

Packaging & Delivery

Package Size

6000.00cm * 3000.00cm * 3000.00cm

Package Gross Weight

1000.000kg

Product Description

View more products,you can click the product keywords below...

View more products,you can click the product keywords below...

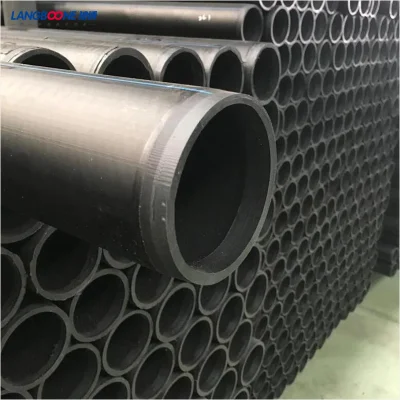

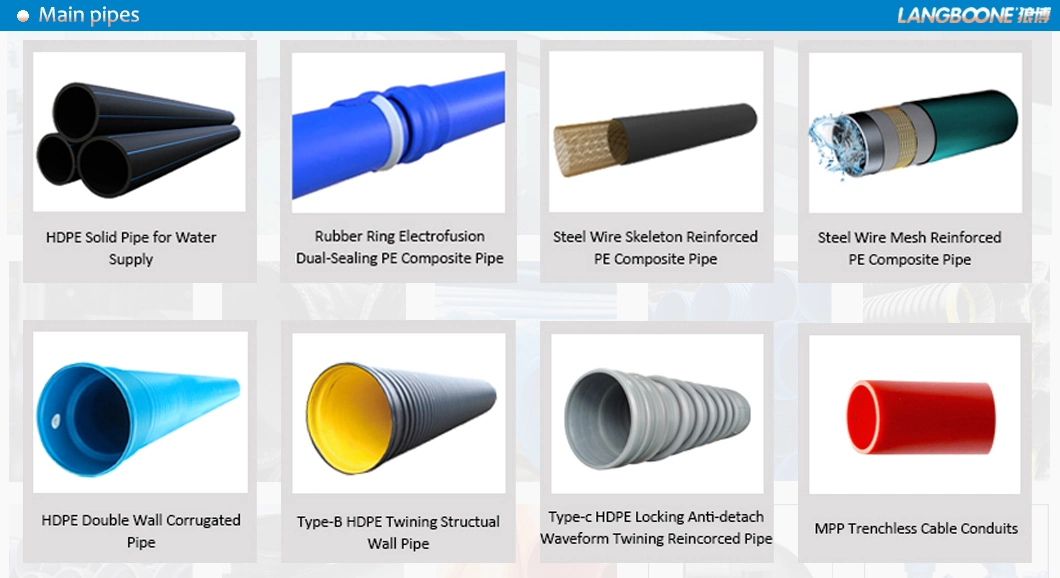

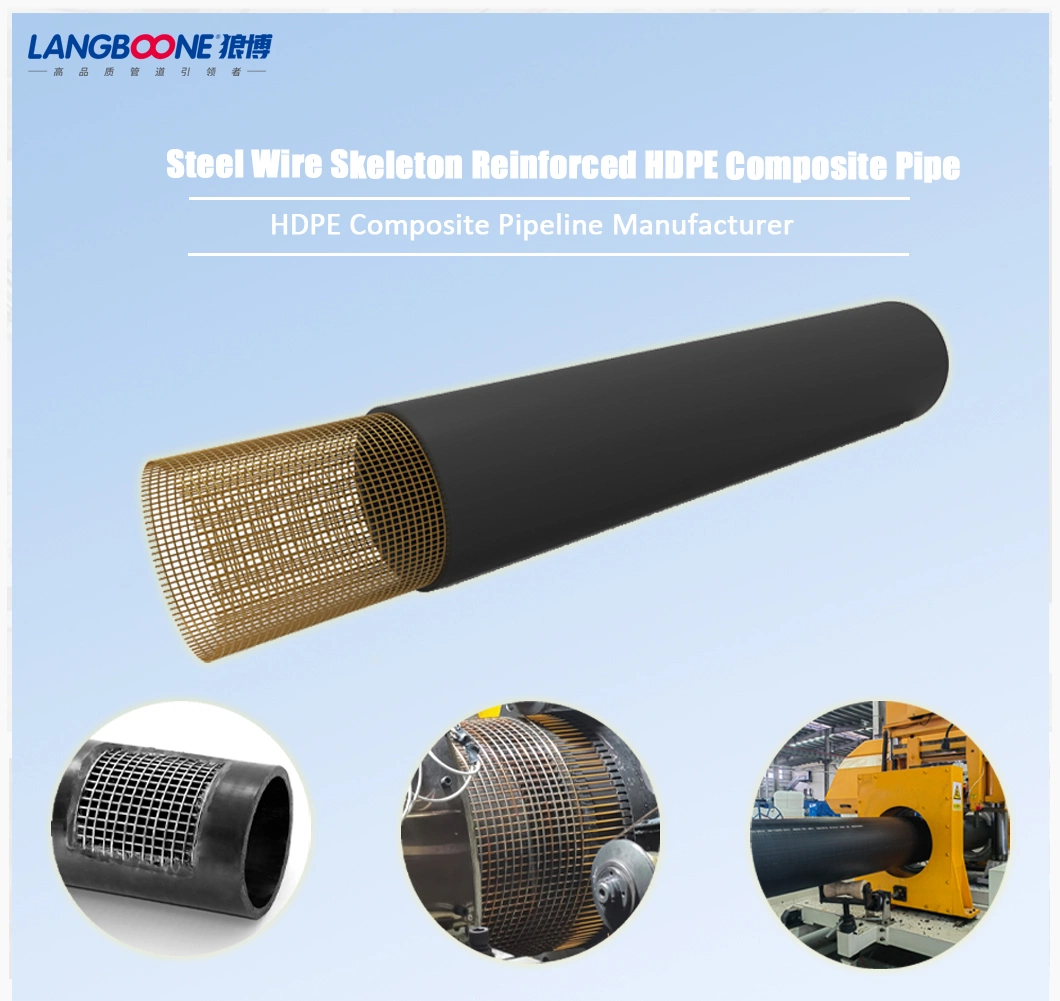

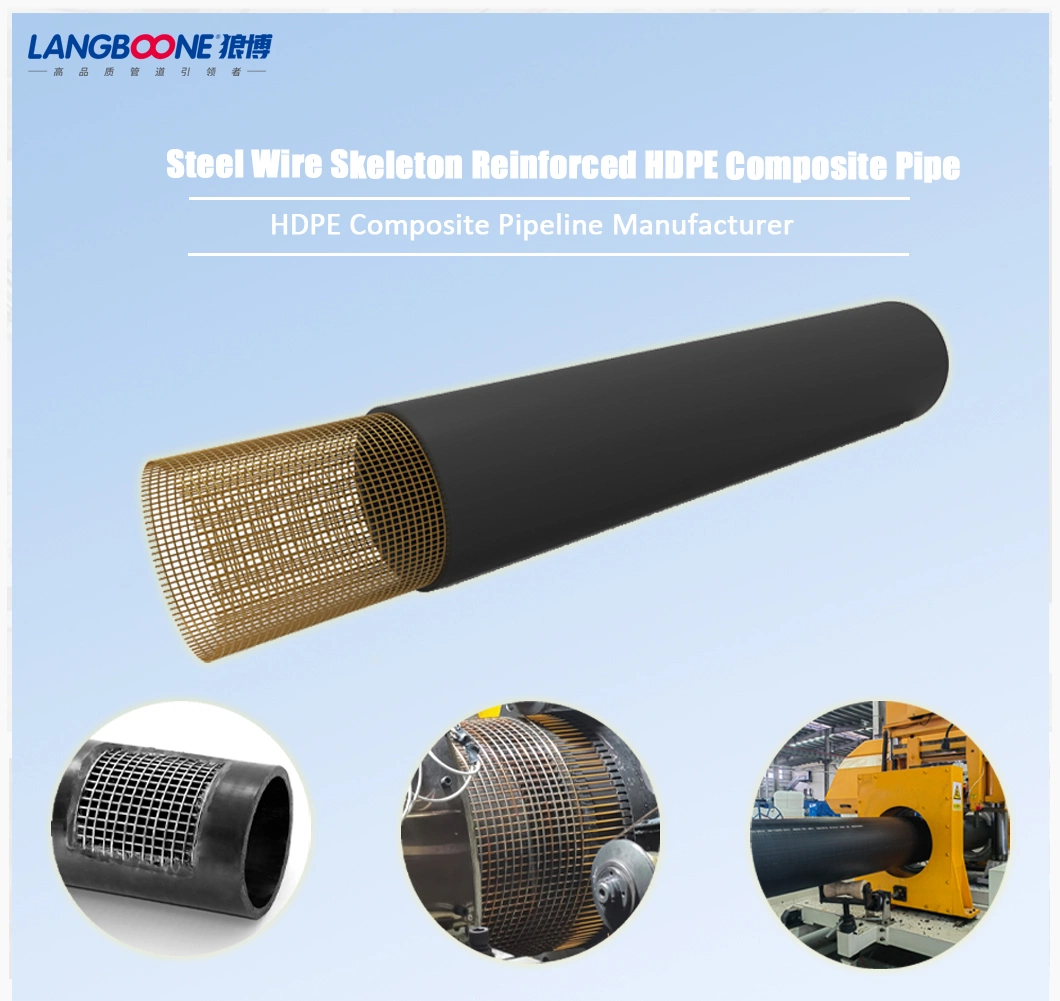

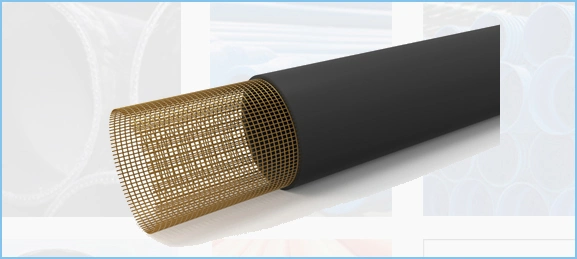

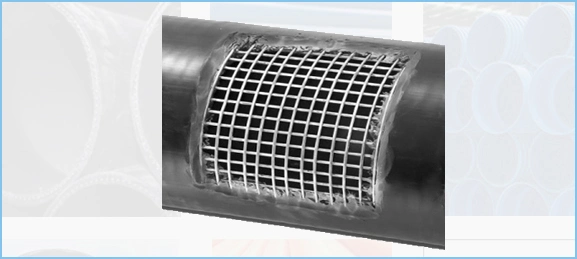

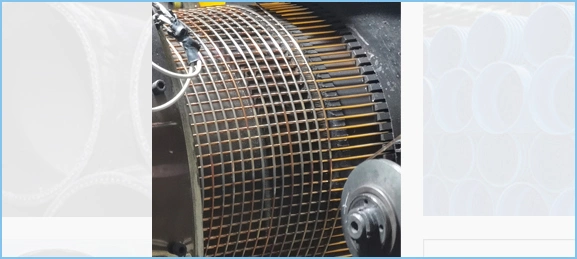

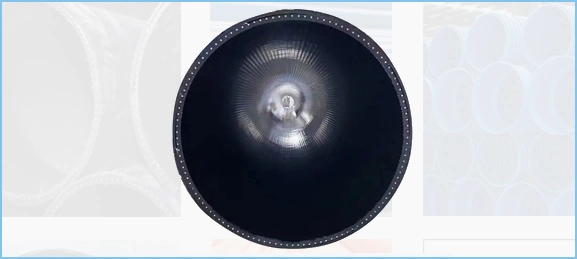

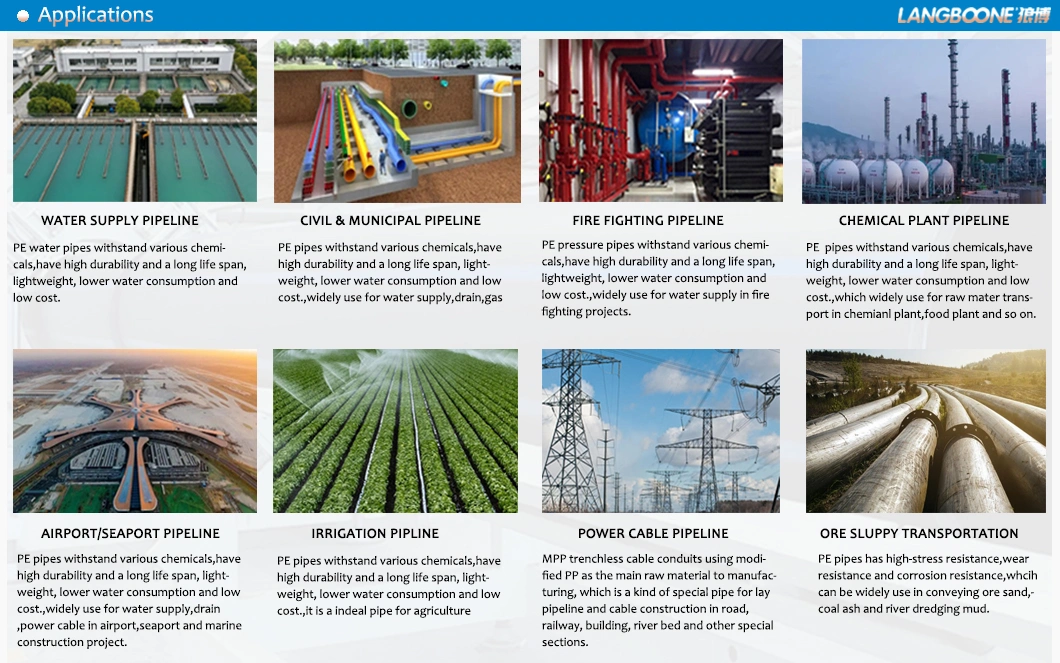

Steel Wire Skeleton Reinforced Composite HDPE Pipe (SRTP) is a new type of medium, high and low-pressure composite pipe with high-strength plastic steel wire as the reinforcement and double-sided composite thermoplastic on the outer and inner layers. Because the reinforcement is covered in continuous thermoplastics, this type of composite pipe not only overcomes the respective shortcomings of steel pipes and plastic pipes but also has the common advantages of steel pipes and plastic pipes.

It is a solution for construction, municipal, petroleum, chemical, and Urgently needed pipes for large-diameter rigid pipes in pharmaceutical, food, mining, gas, and other fields. The pipe fittings used in the steel wire mesh plastic reinforced composite pipe system are electric hot-melt pipe fittings. When connecting, use the internal heating element of the pipe fittings to melt the outer plastic of the pipe and the inner plastic of the pipe fittings to connect them reliably.

It is a solution for construction, municipal, petroleum, chemical, and Urgently needed pipes for large-diameter rigid pipes in pharmaceutical, food, mining, gas, and other fields. The pipe fittings used in the steel wire mesh plastic reinforced composite pipe system are electric hot-melt pipe fittings. When connecting, use the internal heating element of the pipe fittings to melt the outer plastic of the pipe and the inner plastic of the pipe fittings to connect them reliably.

GOOD RESISTANCE TO RAPID CRACK GROWTH

The rapid cracking of the pipeline may instantly cause a major accident of damage to the pipeline of more than ten meters or even thousands of meters. Polyethylene has excellent resistance to rapid crack growth. At the same time, it also has good resistance to scratches and slow crack growth. It is a kind of Safe Plumbing Products.

The rapid cracking of the pipeline may instantly cause a major accident of damage to the pipeline of more than ten meters or even thousands of meters. Polyethylene has excellent resistance to rapid crack growth. At the same time, it also has good resistance to scratches and slow crack growth. It is a kind of Safe Plumbing Products.

DURABLE and ANTI-CORROSION

Polyethylene is an inert material, except for a few strong oxidants, it can resist various chemical media and microbial erosion, no electrochemical corrosion, no need for anti-corrosion coating, and the designed service life is 50 years

Polyethylene is an inert material, except for a few strong oxidants, it can resist various chemical media and microbial erosion, no electrochemical corrosion, no need for anti-corrosion coating, and the designed service life is 50 years

SOFT and BENDABLE

Good flexibility enables small-diameter polypipes to be coiled without pipe connections, reducing material costs, and is used for non-excavation construction. The direction of the pipeline can be changed according to the requirements of the construction method.

Good flexibility enables small-diameter polypipes to be coiled without pipe connections, reducing material costs, and is used for non-excavation construction. The direction of the pipeline can be changed according to the requirements of the construction method.

EASY MOVE and INSTALL

Low density (about 0.94-0.965g/cm3), light weight, easier to transport and install than unimpeded steel pipes or cast iron pipes, reducing construction labor intensity and engineering installation costs.

Low density (about 0.94-0.965g/cm3), light weight, easier to transport and install than unimpeded steel pipes or cast iron pipes, reducing construction labor intensity and engineering installation costs.

1: Higher strength resistance and creep resistance.

1: Higher strength resistance and creep resistance. 2: Excellent stiffness, impact resistance. Low linear expansion coefficient.

3: Smooth inner wall, won't covered with dirt. Low flow resistance, high flow capacity.

4: Both the inner and outer wall are made of plastic, lead the pipe and fittings owns good corrosion resistance.

5: Light weight, easy to transport.

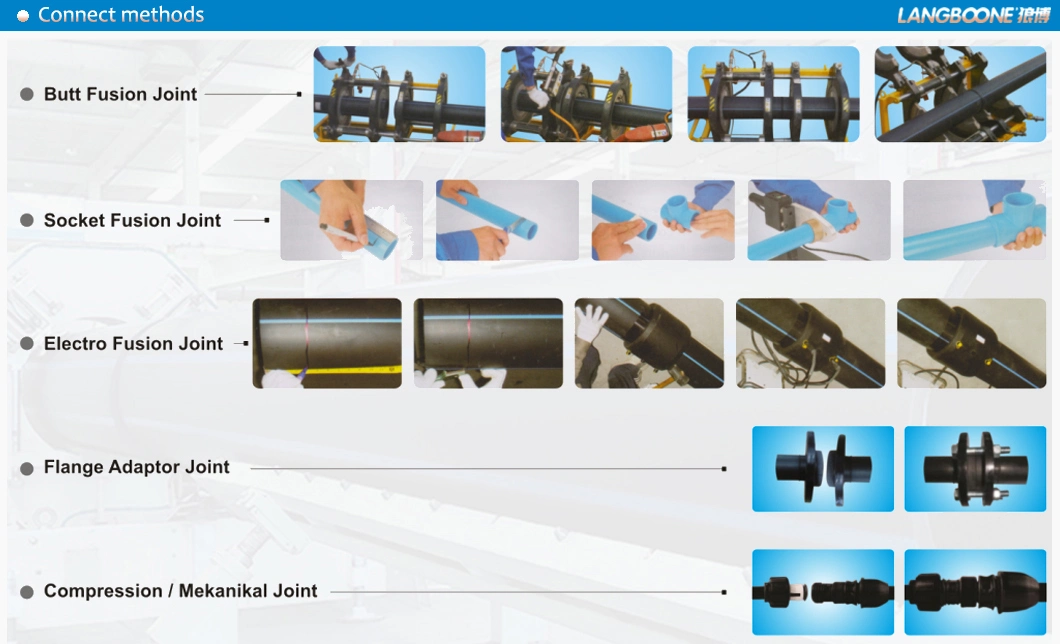

6: Use electro-fusion joint, no leakage in the joint, fast and easy installation.

7: The product is composited with steel wire and plastic, overcome the fast stress crack of plastic pipe.

8: Good abrasion resistance. The product can work for more than 50 years under normal use.

| Steel Wire Skeleton Reinforced HDPE Composite Pipe's Parameter Datas | |||||||

| Norminal Diameter (DN/IN) | Allowable Deviation of ID (%) | PN10/1.0Mpa | PN16/1.6Mpa | PN20/2.0Mpa | PN25/2.5Mpa | PN40/4.0Mpa | Lenght form Steel Wire Skeleton to Inner and Outer Surface |

| Pipe Main Body Thickness (a) and Allowable Deviation (mm) | |||||||

| 50 | ±1 | / | / | / | 9.0+1.4 | 10.6+1.6 | >=1.8 |

| 65 | / | / | / | 9.0+1.4 | 10.6+1.6 | ||

| 80 | / | / | / | 9.0+1.4 | 11.7+1.8 | ||

| 100 | / | 9.0+1.4 | 9.0+1.4 | 11.7+1.8 | 11.7+1.8 | ||

| 125 | / | 10.0+1.5 | 10.0+1.5 | 11.8+1.8 | 12.3+1.8 | ||

| 150 | 12.0+1.8 | 12.0+1.8 | 12.0+1.8 | 12.0+1.8 | 15.5+1.8 | ||

| 200 | 12.0+1.8 | 12.0+1.8 | 12.5+1.9 | 12.5+1.8 | |||

| 250 | ±0.8 | 12.0+1.8 | 12.5+1.9 | 12.5+1.9 | 13.0+1.8 | >=2.5 | |

| 300 | 12.5+1.9 | 12.5+1.9 | 12.5+3.2 | / | |||

| 350 | 15.0+2.4 | 15.0+2.4 | 15.0+2.5 | / | / | ||

| 400 | ±0.5 | 15.0+2.4 | 15.0+2.4 | 15.0+2.6 | / | / | >=3.0 |

| 450 | 15.5+2.4 | 16.0+2.6 | 16.5+2.6 | / | / | ||

| 500 | 15.5+2.6 | 16.0+2.6 | 16.5+2.6 | / | / | ||

| 600 | 19.0+3.0 | 20.0+3.0 | / | / | / | ||

1: The pipe wall thickness is base on the CJ/T 123-2016, HG/T3690-2012,T/CECS 10209-2022 or specified EN/ISO standards

2: Nominal pressure based on water medium temperature ≤20ºC. It should be adjust when the temperature of the medium change.

3: Colour of the pipe is black ,others should be negotiate.

4: Application:water,Corrosive liquid,pulp.

LANGBOONE PE soild pipe and composite pipes can be joined by a variesty of methods includng mechanical joints and a range of thermal fusion procedures,the main methods are Butt Fusion,Electrofuion joint,socket fusion joint,flange adaptor joint and compression joint.

LANGBOONE PE soild pipe and composite pipes can be joined by a variesty of methods includng mechanical joints and a range of thermal fusion procedures,the main methods are Butt Fusion,Electrofuion joint,socket fusion joint,flange adaptor joint and compression joint.