- Overview

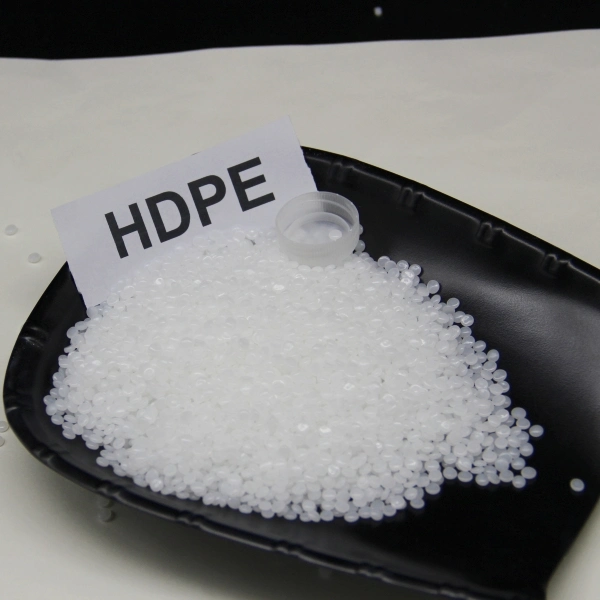

- Product Description

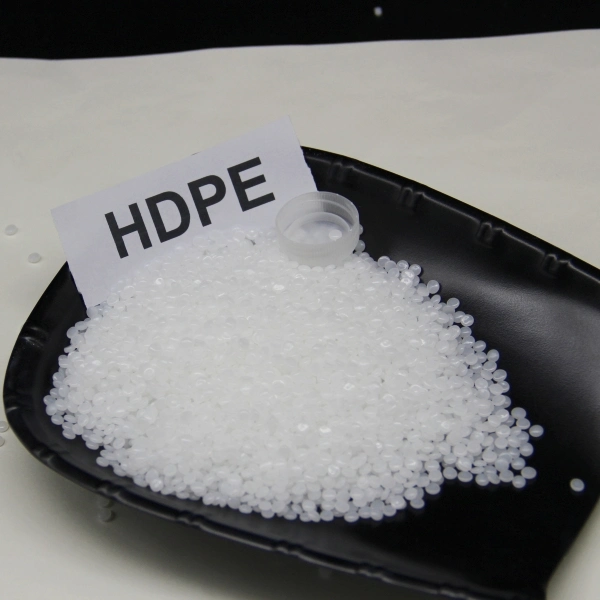

- Detailed Photos

- Product Parameters

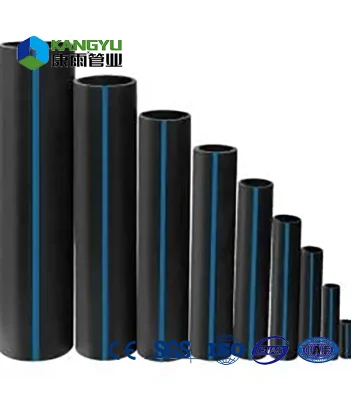

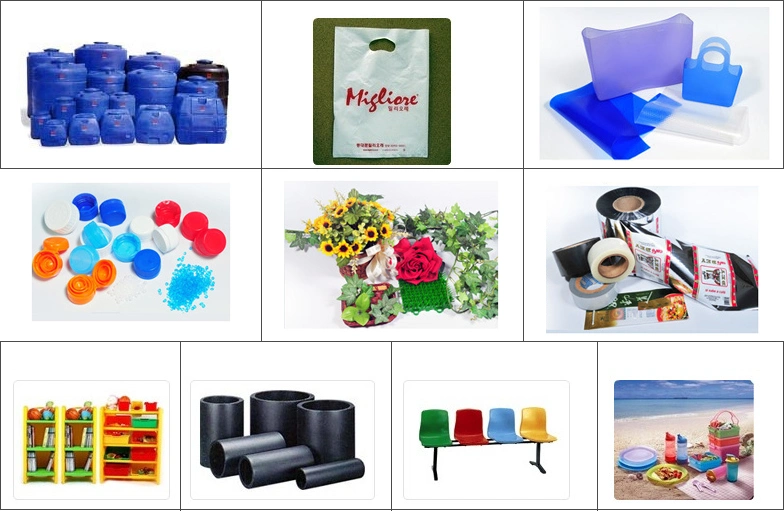

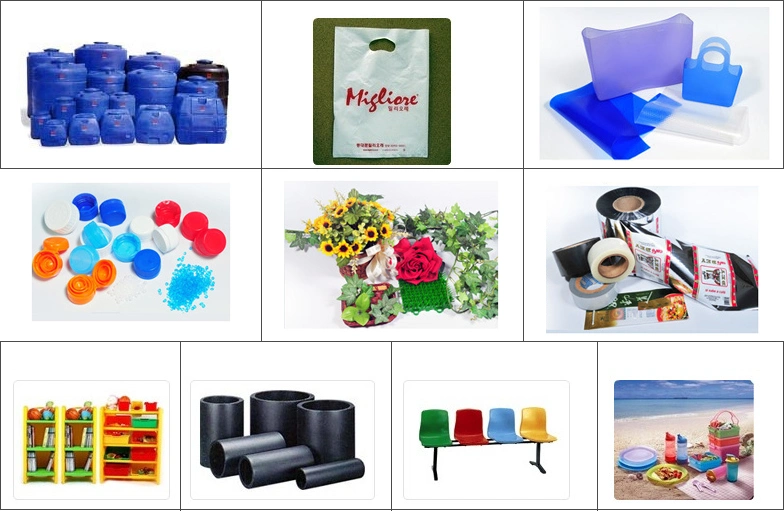

- Application

- Packaging & Shipping

- Company Profile

- product display

- FAQ

Basic Info.

Model NO.

pe 100

EINECS

618-339-3

Material

High Density Polyethylene/HDPE

Usage

General Plastics, Engineering Plastics, Specialty Plastics

Plastic Properties After Heated

Thermoplastic Plastics

Plastic Forming Method

Film Pressure

Color

White

Carrier

HDPE

Type

Virgin HDPE Granule

Name

High Density Polyethylene

Grade

Injection, Extrusion

Process

Injection Molding/Extrusion Molding/Blow Molding

Material Attribute

Blow Molding Grade, Blow Film Grade

Application

Blow Molded Film/Injection Molded Pipe/Extrusion P

Softening Point

125-135°

HS

3901100001

Colour

White or Translucent

Polymer

Homopolymer

Features

High Impact/Controlled Rheology/Good Moldability

Material Shape

Pellets/Granule/ Resin

Form

Granule

Certification

ISO CE

Transport Package

Bag

Specification

25kg

Origin

China

HS Code

3901200091

Production Capacity

100000ton/Year

Packaging & Delivery

Package Size

25.00cm * 20.00cm * 25.00cm

Package Gross Weight

25.000kg

Product Description

HDPE

High density Polyethylene (HDPE): is a highly crystalline non-polar thermoplastic resin produced through the copolymerization of ethylene and a small amount of α-olefin monomer. HDPE is synthesized under low pressure and is therefore also called low-pressure polyethylene. HDPE is mainly a linear molecular structure and has little branching. It has a high degree of crystallization and high density. It can withstand high temperatures and has good rigidity and mechanical strength and anti-chemical corrosion

Film Grade

Blow Grade

Injection grade

2. Competitive prices - directly from factory to customer.

3.Advanced equipments for testing and manufacturing.

4.Professional and good after-sale service

5. Free sample for testing

High density Polyethylene (HDPE): is a highly crystalline non-polar thermoplastic resin produced through the copolymerization of ethylene and a small amount of α-olefin monomer. HDPE is synthesized under low pressure and is therefore also called low-pressure polyethylene. HDPE is mainly a linear molecular structure and has little branching. It has a high degree of crystallization and high density. It can withstand high temperatures and has good rigidity and mechanical strength and anti-chemical corrosion

.

Film Grade

| Item | Test condition | Test Method | Value | Unit |

| Density | ISO 1183 | 0.944-0.955 | g/cm3 | |

| MFR | 190°C/2.16kg | ISO 1133 | 0.03-0.07 | g/10min |

| Tensile strength at yield | ISO 527-2 | 22 | MPa | |

| Elongation at break | ISO 527-2 | >350 | % | |

| ESCR | F50,50°C,100% | ASTM D-1693A | 1000 | h |

| VICAT | ASTM D-1525 | 126 | °C |

Blow Grade

| Item | Test Condition | Test Method | Value | Unit |

| Density | ISO 1183 | 0.950~0.955 | g/cm | |

| MFR | 190°C/2.16kg | ISO 1133 | 1.7~2.5 | g/10min |

| Tensile strength at yield | ISO 527-2 | 24 | MPa | |

| Elongation at break | ISO 527-2 | >600 | % |

Injection grade

| Item | Test Condition | Test Method | Value | Unit |

| MFR | 190°C/2.16kg | ASTM D-1238 | 20 | g/10min |

| Density | --- | ASTM D-792 | 0.954 | g/cm3 |

| Tensile strength at yiled | --- | ASTM D-638 | 28 | MPa |

| Elongation at break | --- | ASTM D-638 | 250 | % |

| Impact tensile strength | --- | ASTM D-1822 | 42 | kJ/m2 |

| |

| 3 | --- |

|

|

| 127 | °C |

-

1.Fiber ( Carpet, Textiles, Upholstery, etc.)

2.Film ( shopping bags, casting film, multilayer film, etc.)

3.Blow Molding ( Medical & Cosmetic container, Lubricant & Paint container, etc)

4.Extrusion Molding ( Sheet, Pipe, Wire & Cable, etc.)

5.Injection Molding ( Automotive, Electronic, Construction, House wares, Furniture,

Toys, etc.)

25kg/ carton or 25kg/bag, or per your requirement

25kgs net weight in PP woven or PE plastic bag about 20 tons for 20" container

Since 2020, the company has been engaged in the production of plastic raw materials. Located in Shijiazhuang, Hebei Province, China, the company covers an area of 800 mu and has more than 5,000 employees. The main products are carbon black, master, modifier (pvc, PP, pa6, pa66, pbt, abs), filler master, flame retardant, antioxidant, flexible agent, plasticizer and other plastic raw materials (ldpe, hdpe, lldpe, pvc, pva, pbt, eva abs, eps, gpps, hips, pc Pet, etc.). After years of efforts and development, we have reached a certain scale, with a technical service team to provide high-quality, professional services for users

1.We are able to provide customized service based on your requirements.

2. Competitive prices - directly from factory to customer.

3.Advanced equipments for testing and manufacturing.

4.Professional and good after-sale service

5. Free sample for testing