Basic Info.

Model NO.

EF belt

Standard

Standard

Application

Pipeline Joint Closure

Color

Black

Coustomized

Coustomized

Transport Package

Standard Package

Specification

EN253, EN448, EN728, ISO1133, ISO8501-1. ISO9001

Trademark

Huashida

Origin

Qingdao, China

HS Code

3917400000

Production Capacity

2000sets/Day

Product Description

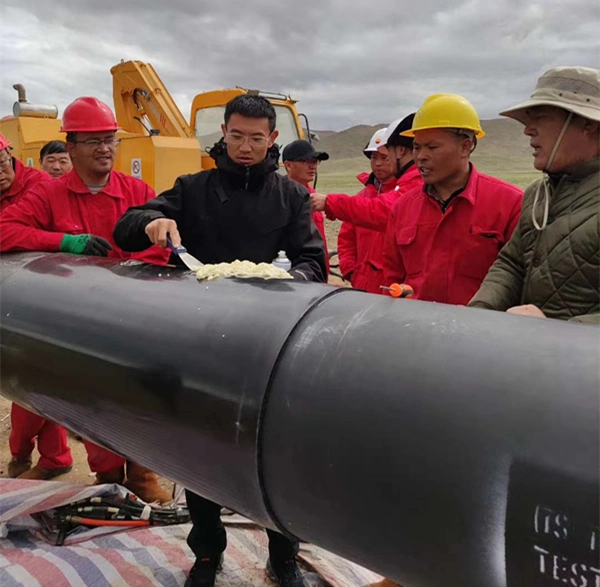

PU foaming insulation pipeline joint HDPE pipe electro-fusion tape coupling

PU foaming insulation pipeline joint HDPE pipe electro-fusion tape coupling Product description:

It is a kind of connecting pipe fitting what is widely used on anti-corrosion, especially on Directly buried pre-insulated pipes field joint. It is made by Polyethylene sheets complex with the electro-fusion wire.

Performance:

1. Waterproof;

2. Able to withstand axial forces initiated by axial movements of the pipe in the ground;

3. Able to withstand radial forces and bending moments;

4. Able to withstand effects of temperature and temperature variations.

5. Have the same thickness of the line pipe insulation layer.

Technical parameters:

| Specification | |||

| Steel pipe outside diameter (mm) | PE outside casing diameter (mm) | Width(mm) | Tic.mm |

| DN159 | 285 | 600 | 4 |

| DN219 | 315 | 600 | 4 |

| DN273 | 365 | 600 | 4 |

| DN325 | 420 | 600 | 5 |

| DN377 | 500 | 600 | 5 |

| DN426 | 550 | 600 | 6 |

| DN478 | 630 | 600 | 6 |

| DN529 | 655 | 600 | 6 |

| DN630 | 760 | 600 | 8 |

| DN720 | 850 | 600 | 8 |

| DN820 | 960 | 600 | 10 |

| DN920 | 1054 | 600 | 10 |

| DN1020 | 1155 | 600 | 12 |

| DN1220 | 1380 | 600 | 12 |

Technical Data:

All of test according with the EN253-2003,ISO1183-2004,ISO6964-1986,EN728-1997

| Final Test | Unit | Standard | Test Result | Result |

| Raw material density | g/CM3 | ≥0.935 | ≤0.961 | PASS |

| Raw material melt flow rate | g/10min | ≤0.50 | 0.46 | PASS |

| Appearance check | / | Inernal and external surfaces is clean and free from other defects. | Pass | PASS |

| Heat reversion | % | ≤3;shall not show any cracks | 0.89,No cracks | PASS |

| Tensile yield strength | Mpa | ≥19 | 20.2 | PASS |

| Elongation at break | % | ≥350 | 656 | PASS |

| Stress crack resistance | h | ≥300 | Pass | PASS |

PLEASE TELL ME YOUR DETAIL PIPE DIA. AND DETAIL DEMAND.