Basic Info.

Model NO.

HSD

Customized

Customized

Condition

New

After-sales Service

Overseas Installation, Free Technical Supporting

Material

PE

Control System

Siemens PLC

Pipe Uasge

Water Supply, Gas Supply

Transport Package

Standard Package

Specification

20-1200mm

Trademark

HSD

Origin

Qingdao China

HS Code

8477209000

Production Capacity

50 Units/Year

Product Description

Yellow Black Underground Buried Direct Burial Plastic PE HDPE Poly Polyethylene Water Natrural Gas Supply Pipe Extrusion Production Line

Description

PE gas water supply pipe production line is mainly used to extrude PE pressure pipes, pipe diameter ranging 20-1200mm.

The produced pipe has smooth surface and uniform wall thickness, the specification can meet the international standards of the product. The pipes are widely used in municipal water supply, urban gas transportation and other fields.

The equipment can apply special extrusion molds and adopt multi-layer co-extrusion technology to reduce production costs.

PE pipe extrusion line mainly includes single screw extruder, molds, vacuum calibrating water tank, spray water cooling tank, haul-off machine, cutting machine and bracket.

Application

Underground water supply pipe

Underground gas supply pipe

Advantages

- Use high-efficiency extruder, equipped with barrier screw and mixing head, new slotted barrel, with good plasticizing and mixing effect, large extrusion volume and good stability.

- Use spiral-type die head, which can work with lower melt temperature, with good mixing performance, lower cavity pressure and good stability.

- Exclusive technology for sizing and cooling system. Water film lubrication and water ring cooling are used to meet the requirements of HDPE and PP materials to ensure the stability of the diameter and roundness of the pipe in high-speed production.

- The production line can be controlled by PLC, with a well-experienced man-machine interface, and all process parameters can be set and displayed through the touch screen.

- The application of extrusion die and multi-layer compound co-extrusion technology greatly reduces production costs.

| Style | SPEG-110 | SPEG-160 | SPEG-250 | SPEG-450 | SPEG-630 |

| Diameter(mm) | ∮20-∮110 | ∮50-∮160 | ∮63-∮250 | ∮110-∮450 | ∮315-∮630 |

| Capacity(kg/h) | 250 | 300 | 350 | 600 | 900 |

| Installed power(kw) | 180 | 200 | 210 | 298 | 522 |

| Outer size(m) | 36×1.8×3 | 36×1.8×3 | 36×1.8×3 | 43×3.02×3.0 | 57.8×3.4×3.9 |

| Weight(T) | 12.5 | 13 | 14.5 | 27.5 | 41 |

Service

Provide foundation plans and pre-installation documents

Overseas equipment installation and commissioning

Free technical support

Employee training

One year warranty

Production line details

1. Single Screw Extruder

Single screw extruder is composed of AC motor, hard toothed surface reduction gear, extruding system, heating and cooling system, and electrical controlling part. AC motor transfer the power to reduction gearbox via V-belt wheel and make screw rotate at certain speed to adapt to extruding all kinds of plastics.

2. Die-Head

Die-head is mainly composed of mandril, neck mold, spiral body, cover, die-head body, bolts, and heating rings. The inside surface touching with plastic materials is polished and chrome plated to ensure plastic materials flow smoothly and to ensure no rusting. The uniformity of pipe wall thickness can be adjusted by bolts. The copper calibrating sleeve fixed in die-head is mainly used to cool down the fresh pipe and to calibrate the pipe outer diameter.

3. Vacuum forming tank

Vacuum forming tank is mainly composed of frame, stainless steel tank, vacuum system, spray cooling system, back and forth mobile device. When it is at work, the vacuum pump exhausts the air from the sealed tank to pressurize the fresh pipe cling to calibrating copper sleeve and to realize calibrating the pipe outer diameter. Spray cooling system is used to cool down the extruded pipe by water. Spray nozzles spray cooling water from all directions on pipe surface to cool down the pipe promptly.

4. Water Cooling Tank

Water cooling tank is mainly composed of frame, stainless steel tank, and spray cooling system. Spray cooling system is used to cool down the pipe further and to realize cooling completely and forming.

5. Haul-off Machine

Haul-off machine is mainly composed of driving device, haul-off chain, clamping structure, adjusting system, side plate, and foundation bed. Haul-off tracks are AC motor driven and adopt frequency control of speed to adapt to different pipes extruding speed. It is also equipped with automatic length measuring device to realize cutter cutting at set length.

6. No-Dust Planetary Cutter

It adopts blade punching principle to realize no-dust cutting. It is mainly composed of cutting device, clamping device, structure synchronous mobile device, and frame.

7. Discharging Frame

The table surface is made of stainless steel. It adopts pneumatic overturn and discharging automatically.

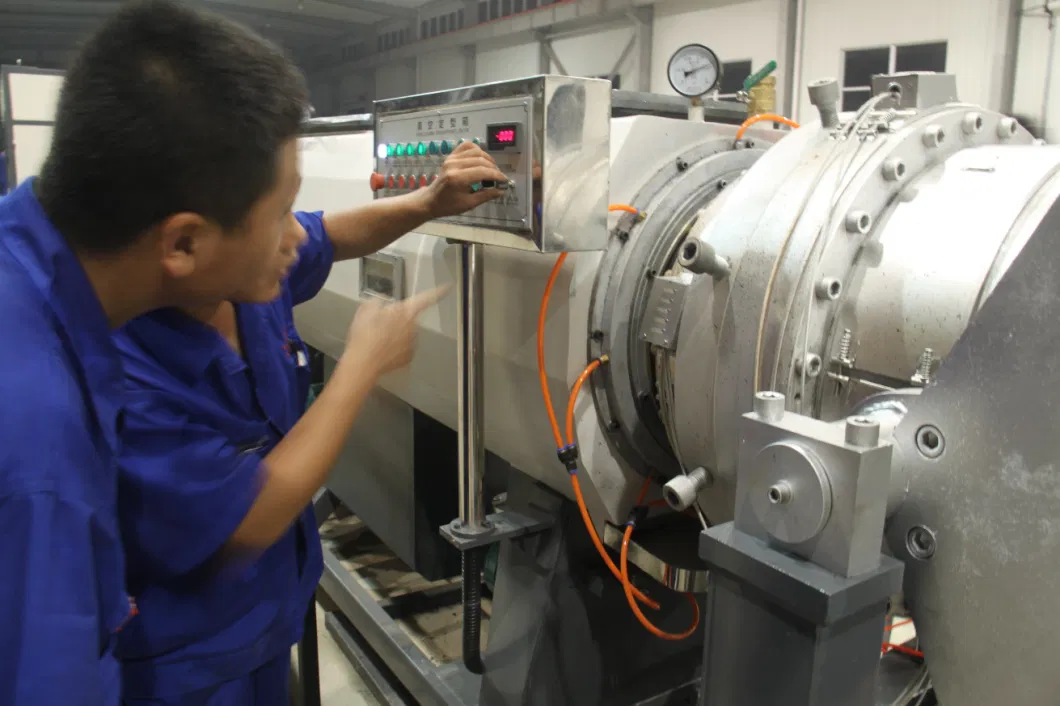

HUASHIDA Workshop

Equipment Delivery

Customers' visiting

Customers' visiting

At overseas exhibitions