Basic Info.

Model NO.

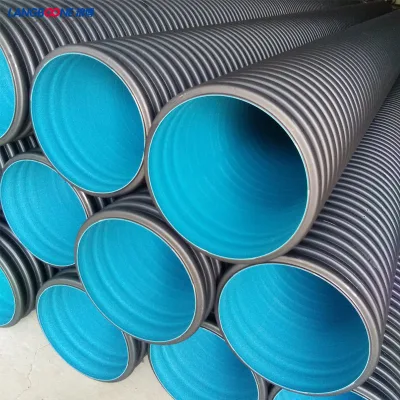

HDPE Double Wall Corrugated Pipe

Contraction Percentage

<0.4%

Tensile Strength

3.9MPa

Production Capaction

300,000t/Year

Certificate

ISO9001, CE, Wras

Production Standard

GB/CE/ISO....

Length

6m

Ring Stiffness Kn/M

Sn8,Sn10,Sn12,Sn16

Transport Package

Customized

Specification

DN100-DN800

Trademark

LANGBOONE

Origin

China

HS Code

3917210000

Production Capacity

300, 000t/Year

Packaging & Delivery

Package Size

1000.00cm * 1000.00cm * 1000.00cm

Package Gross Weight

1000.000kg

Product Description

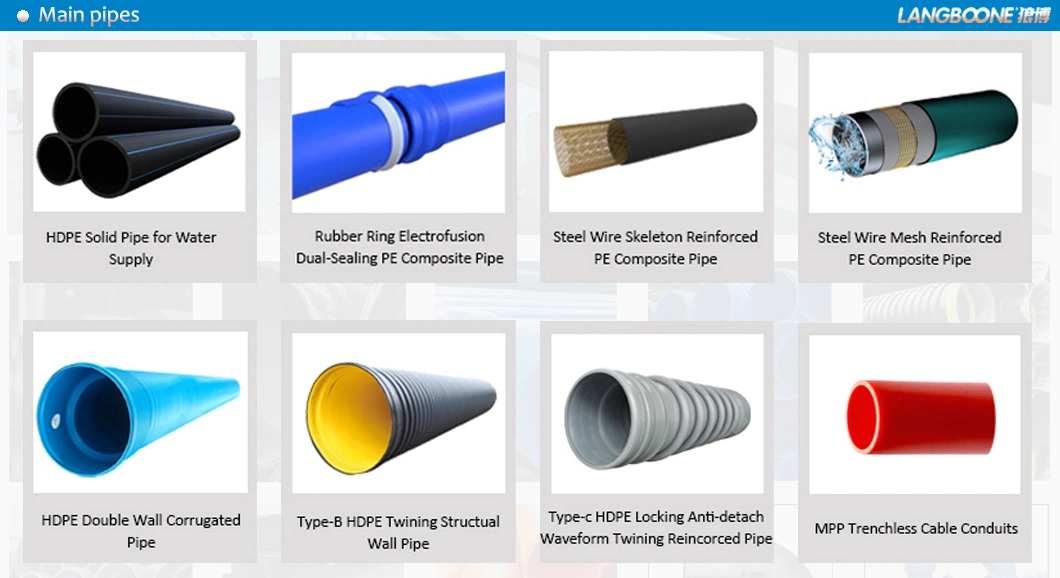

View more products,you can click the product keywords below...

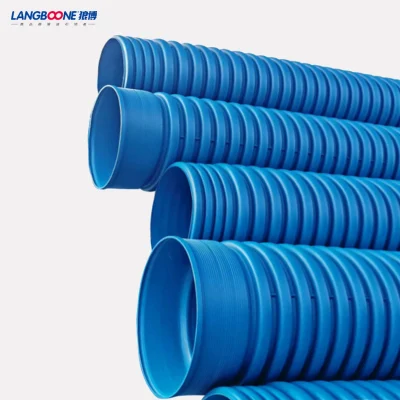

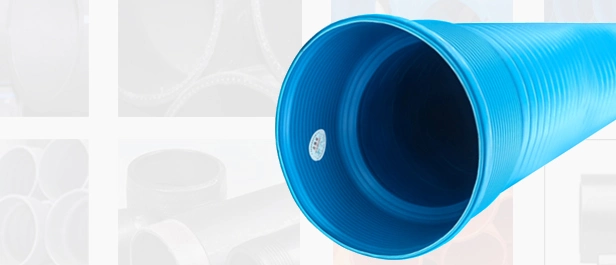

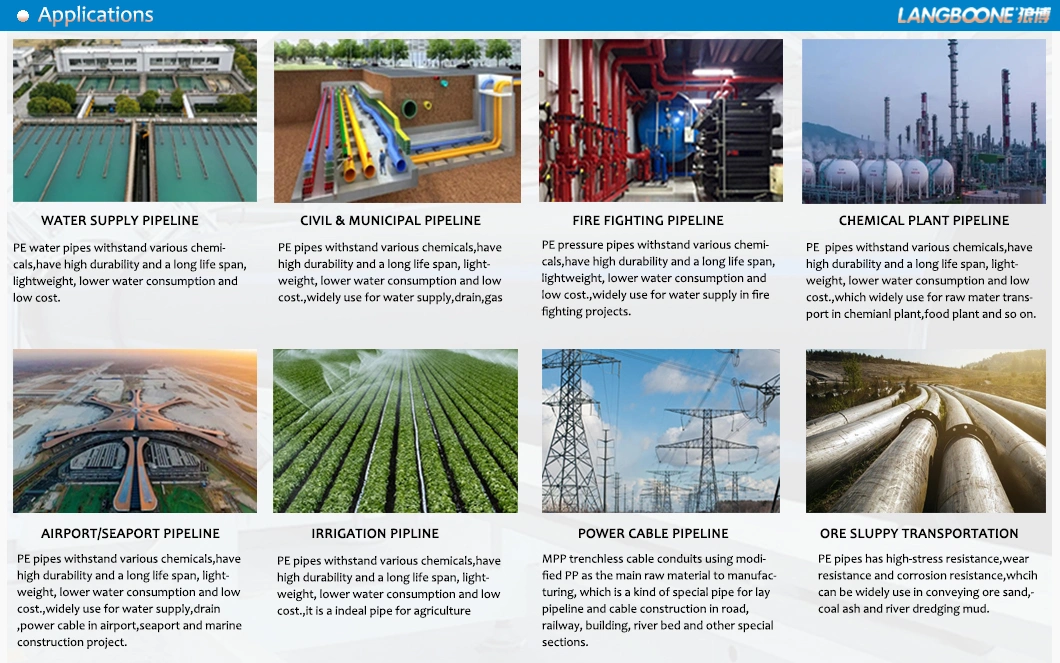

Polyethylene (HDPE) Double Wall Corrugated Pipe is a new type of lightweight pipe made of high density polyethylene raw materials. It has the characteristics of light weight, high pressure resistance, good toughness, fast installation and long service life. Due to excellent double wall structure design which greatly reduces the production cost compared with other pipes and it is widely used at home and abroad to replace concrete pipe and cast iron pipe because of convenient connection and reliability

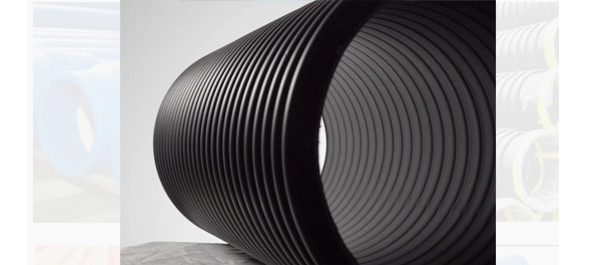

Strong resistance to external pressure: the annular corrugated structure of the outer wall greatly enhances the ring stiffness of the pipe, thus enhancing the resistance of the pipe to soil load. In this aspect, HDPE double-wall corrugated pipe has obvious advantages over other pipes.

Low project cost: under the same load condition, the HDPE double-wall bellows only need a thinner wall to meet the requirements.Therefore, compared with the solid wall tube of the same material specification, it can save about half of the raw material, so the cost of HDPE double wall bellows is also lower.This is another outstanding feature of the pipe.

Convenient construction: due to the light weight of HDPE double-wall corrugated pipe, it is convenient to carry and connect, so the construction is quick and the maintenance is simple.

Long service life: the service life of HDPE double-wall bellows can be more than 50 years under the condition of not being exposed to the sunlight and ultraviolet ray.

Durable: Corrosion resistance: good material stability, effective corrosion resistance Impact resistance: good toughness, high impact resistance Low temperature resistance: can be used at -60ºC High wear resistance: wear resistance is better than metal pipes

Comprehensive economical features, Environmental health: new polyethylene as raw material, no toxic additives, no scaling, no bacteria breeding

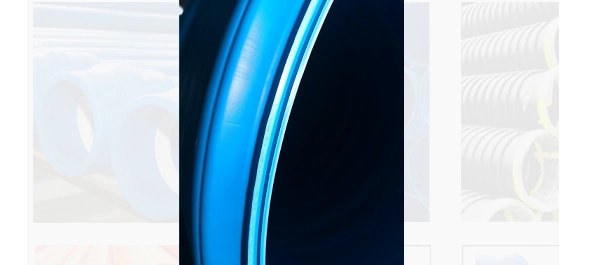

RELIABLE CONNECTION

Hot-melt, electro-fusion connection ensures the identity of the interface material, structure and the pipe body itself, and the tensile strength and burst strength of the interface are higher than the pipe body. The co-extrude interface is clear, long-term sunshine is not easy to fade, and the depth of embedding in the pipe wall thickness is small, so as to avoid welding defects.

Hot-melt, electro-fusion connection ensures the identity of the interface material, structure and the pipe body itself, and the tensile strength and burst strength of the interface are higher than the pipe body. The co-extrude interface is clear, long-term sunshine is not easy to fade, and the depth of embedding in the pipe wall thickness is small, so as to avoid welding defects.

1: Lightweight, quick construction, and lower cost.

1: Lightweight, quick construction, and lower cost.2: The buried service life is more than 50 years.

3: Polyethylene is a hydrocarbon polymer, its molecules are non-polar and resistant to acid and alkali corrosion.

4: The raw materials are green environmental protection materials, non-toxic, non-corrosive, non-scaling, and can be recycled and reused.

6: The applicable temperature range is wide, the pipeline will not break in an environment of -60ºC, and the maximum temperature of the conveying medium is 60ºC.

7: The cost of the comprehensive project is basically equivalent to that of concrete, and the operating cost is low.

8: No foundation is needed when the soil is good.

| HDPE Double Wall Corrugated Pipe's Parameter Datas | |||||

| Norminal Inner Diameter (DN/IN) | Min.Average Inner Diameter | Min. Wall Thickness of the Inside Layer | Min. Wall Thickness of the Inside Layer under a Hollow Section | Min. Wall Thickness of the Outside Layer under a Hollow Section | Min.Length of Engagement of Socket |

| DN/IN | dem.min | e.min | e1.min | e3.min | A.min |

| 100 | 95 | 1.0 | 0.8 | 0.7 | 32 |

| 125 | 120 | 1.2 | 1.0 | 0.8 | 38 |

| 150 | 145 | 1.3 | 1.0 | 0.8 | 43 |

| 200 | 195 | 1.5 | 1.1 | 0.9 | 54 |

| 225 | 220 | 1.7 | 1.4 | 0.9 | 55 |

| 250 | 245 | 1.8 | 1.5 | 1.0 | 59 |

| 300 | 294 | 2.0 | 1.7 | 1.0 | 64 |

| 400 | 392 | 2.0 | 1.7 | 1.0 | 64 |

| 500 | 490 | 3.0 | 3.0 | 1.8 | 85 |

| 600 | 588 | 3.5 | 3.5 | 2.7 | 118 |

| 1000 | 985 | 5.0 | 5.0 | 3.0 | 140 |

| 1200 | 1185 | 5.0 | 5.0 | 3.0 | 162 |

1: The pipe wall thickness is base on the GB/T19472.1-2019 or specified EN/ISO standards

2: Nominal pressure based on water medium temperature ≤20ºC. It should be adjust when the temperature of the medium change.

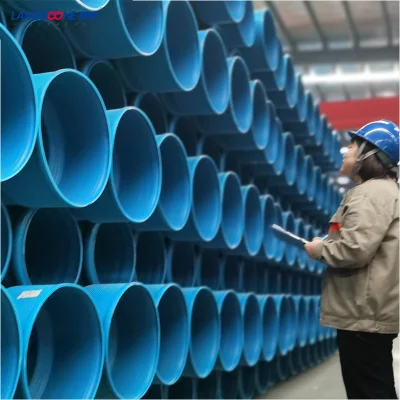

3: Colour of the pipe is BLUE ,others should be negotiate.

4: Application:water,Corrosive liquid,pulp.

LANGBOONE HDPE double wall corrugated pipe and type-b,type-c pipes can be joined by a variesty of methods includng mechanical joints and a range of thermal fusion procedures,the main methods are Butt Fusion,Electrofuion joint,socket fusion joint,flange adaptor joint and compression joint.

LANGBOONE HDPE double wall corrugated pipe and type-b,type-c pipes can be joined by a variesty of methods includng mechanical joints and a range of thermal fusion procedures,the main methods are Butt Fusion,Electrofuion joint,socket fusion joint,flange adaptor joint and compression joint.